Toward realization of lightweight and high strength structural materials

Credit: Nagoya University

Nagoya, Japan – Single-walled carbon nanotubes should theoretically be extremely strong, but it remains unclear why their experimental tensile strengths are lower and vary among nanotubes. A team at Nagoya University, Kyoto University, and Aichi Institute of Technology directly measured the tensile strengths of individual structure-defined single-walled carbon nanotubes, revealing key insights into the relationship between their structure and strength.

Carbon nanotubes have been predicted as game-changing structural materials due to their outstanding theoretical strength per weight (Fig. 1a). They have even encouraged the construction of a space elevator, which is impossible using other existing materials.

Carbon nanotubes have a variety of structures with various carbon atom alignments. Depending on the number of concentric layers, carbon nanotubes are classified as single-walled or multi-walled nanotubes (Fig. 1b). Additionally, structures of the concentric layers are specified by diameter and chiral angle (Fig 1c) or a pair of integers (n,m) called as chiral indices.

Because of the difficulty in the selective synthesis of single structure nanotubes, the systematic studies of their mechanical properties require the structure determination of each sample nanotubes. However, due to their nanoscale size and difficulty in handling them, the tensile test of “structure-defined” single-walled carbon nanotube has not been achieved yet. The previous studies have shown that the tensile strength of real carbon nanotubes, including multiwalled and structure-undefined single-walled carbon nanotubes, is typically lower than the ideal case. Furthermore, the strengths considerably varied among the measured samples. This scattering poses a critical problem regarding their practical use in macroscopic structural materials such as yarns composed of many carbon nanotubes, because their fracture will be initiated from the weakest nanotubes. The lack of a systematic experimental study on the structure dependence has long obscured the fracture mechanism of real carbon nanotubes, and, therefore, has hindered the development of a macroscopic structural material with an ideal strength-to-weight ratio.

A team of physicists, chemists, and mechanical engineers designed the experimental schemes for the tensile test of structure-defined single-walled carbon nanotubes (hereafter, referred to as nanotubes). Individual nanotubes were synthesized over a micrometer-scale open slit via ambient alcohol chemical vapor deposition methods (Fig. 2a). Broadband Rayleigh scattering spectroscopy was employed to determine the nanotube structures (Fig. 2b). Then, the individual structure-defined nanotubes were picked up with a micro fork (Fig. 2c), and transferred onto a homemade microelectromechanical system (MEMS) device (Fig. 2d). Each individual nanotube was suspended and cramped between a pair of sample stages that were connected to a micro load-cell and actuator for the direct force measurement and uniaxial tensile force application, respectively (Fig. 2d). Figure 2e shows an image at the moment the nanotube fractured during tensile loading. The force was directly evaluated from the measured displacement of the load-cell stage equipped with micro springs according to Hooke’s law.

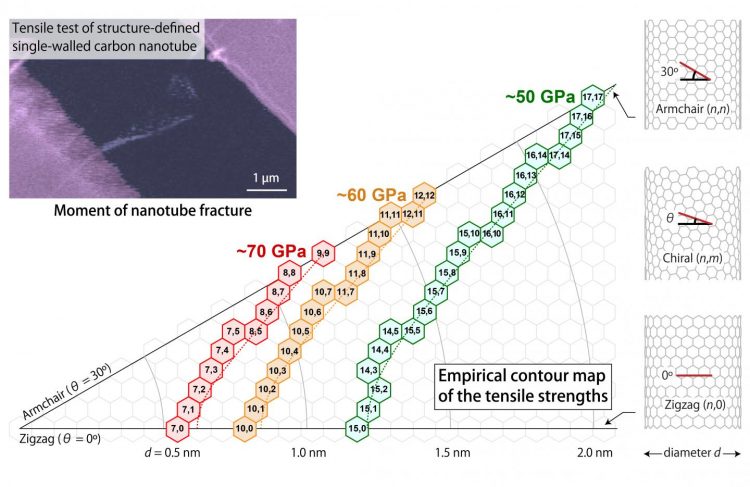

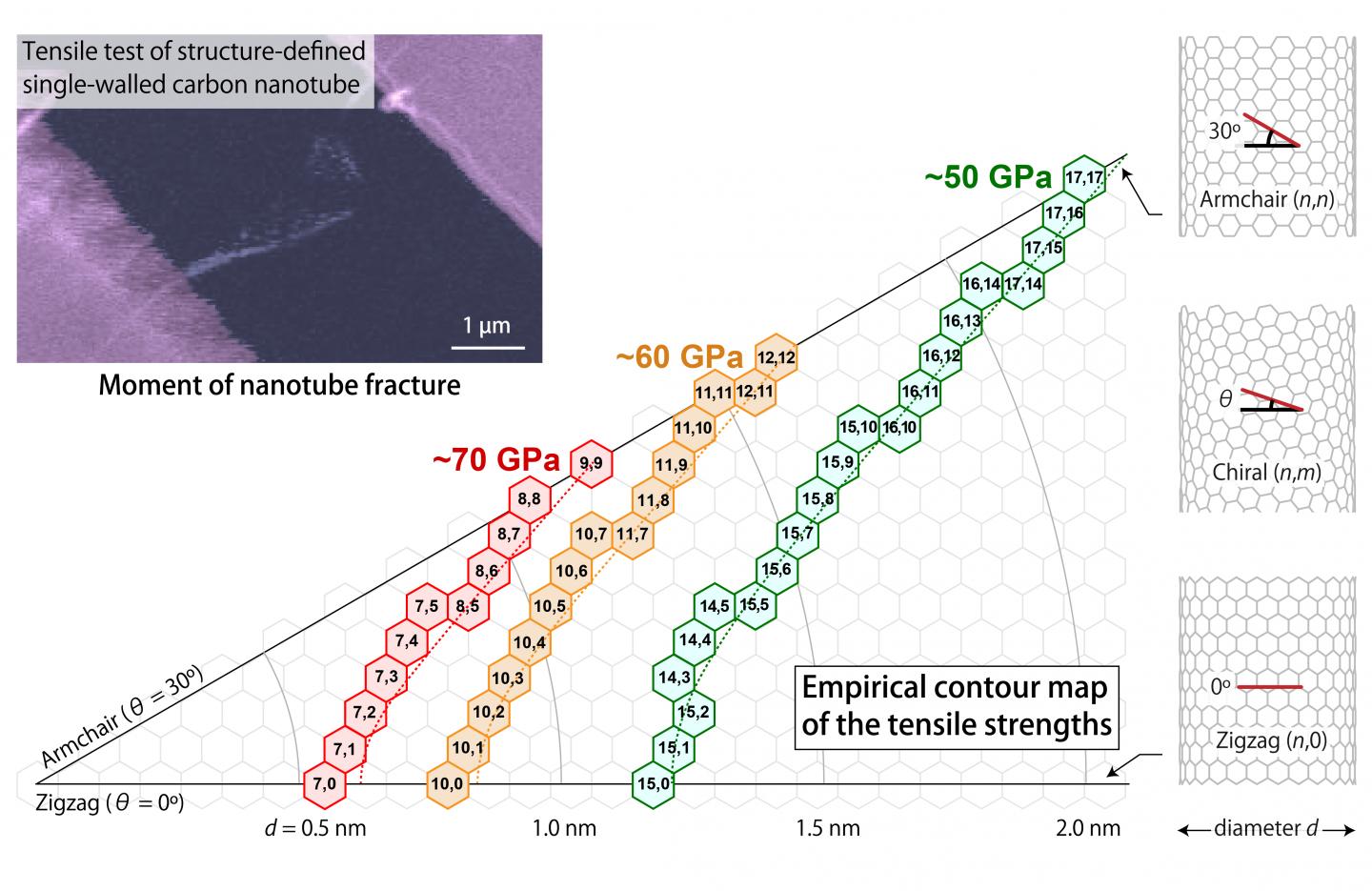

The team succeeded in measuring the tensile strengths of 16 structure-defined nanotube species. Figure 3a summarizes the structure dependence of the measured ultimate tensile nanotube strengths. The strengths are seemingly dependent on both the chiral angle (Fig. 3b) and diameter (Fig. 3c) of the nanotubes.

The team found the clear relation between strengths and structures by considering directions of carbon-carbon bonds against the direction of the tensile load and stress concentration at structural defects (Fig. 4). Furthermore, the team developed an empirical formula to predict the real nanotubes’ strengths. This empirical formula provides the most favorable nanotube structures that should be selectively synthesized toward the strongest material (Top of contents). Fortunately, the suggested types of the nanotube structures are not well-constrained. Although there remain a number of severe problems, including structure selective synthesis of defect-less nanotubes, the growth of long nanotubes, and making ropes with keeping their strength, this finding provides one of the fundamental insights for developing super-strong and ultra-lightweight materials for use in the construction of the safest and most fuel-efficient transport equipment or massive architectural structures.

###

Media Contact

Aki Miura

[email protected]

Original Source

https:/

Related Journal Article

http://dx.