Credit: American Chemical Society

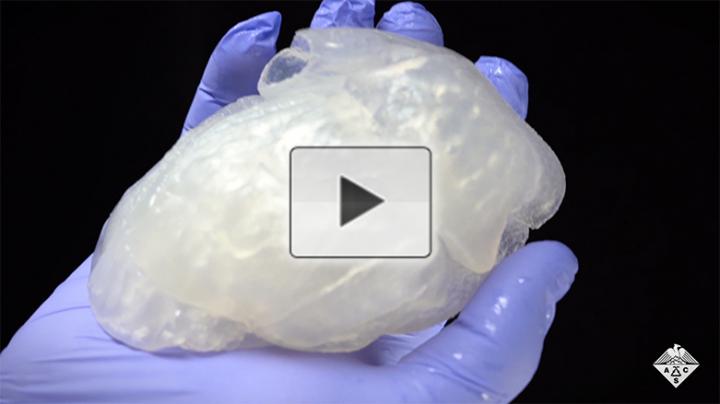

Full-size, realistic models of human organs could help surgeons train and practice before they cut into a patient. However, it’s been challenging to make inexpensive models of a size, complexity and material that simulates human organs. Now, researchers reporting in ACS Biomaterials Science & Engineering have developed a way to 3D print a full-size model of a patient’s own heart. Watch a video of how they made the 3D organ here.

For complex heart surgeries, having a chance to plan and practice on a realistic model could help surgeons anticipate problems, leading to more successful outcomes. Current 3D printing techniques have been used to make full-size organ models, but the materials generally don’t replicate the feel or mechanical properties of natural tissue. And soft, tissue-like materials, such as silicone rubbers, often collapse when 3D printed in air, making it difficult to reproduce large, complex structures. Eman Mirdamadi, Adam Feinberg and colleagues recently developed a technique, called freeform reversible embedding of suspended hydrogels (FRESH), which involves 3D printing soft biomaterials within a gelatin bath to support delicate structures that would otherwise collapse in air. However, the technique was previously limited to small objects, so the researchers wanted to adapt it to full-size organs.

The team’s first step was to show that alginate, an inexpensive material made from seaweed, has similar material and mechanical properties as cardiac tissue. Next, the researchers placed sutures in a piece of alginate, which held even when stretched — suggesting that surgeons could practice stitching up a heart model made from the material. In preparation for making the heart model, the team modified their FRESH 3D printer to make larger objects. They used this device and magnetic resonance imaging (known as MRI) scans from a patient to model and print a full-size adult human heart, as well as a section of coronary artery that they could fill with simulated blood. The heart model was structurally accurate, reproducible and could be handled outside of the gelatin bath. The method could also be applied to printing other realistic organ models, such as kidneys or liver, the researchers say.

The authors acknowledge funding from the Office of Naval Research, the U.S. Food & Drug Administration and the National Institutes of Health.

The abstract that accompanies this paper can be viewed here.

The American Chemical Society (ACS) is a nonprofit organization chartered by the U.S. Congress. ACS’ mission is to advance the broader chemistry enterprise and its practitioners for the benefit of Earth and its people. The Society is a global leader in providing access to chemistry-related information and research through its multiple research solutions, peer-reviewed journals, scientific conferences, eBooks and weekly news periodical Chemical & Engineering News. ACS journals are among the most cited, most trusted and most read within the scientific literature; however, ACS itself does not conduct chemical research. As a specialist in scientific information solutions (including SciFinder® and STN®), its CAS division powers global research, discovery and innovation. ACS’ main offices are in Washington, D.C., and Columbus, Ohio.

To automatically receive news releases from the American Chemical Society, contact [email protected].

Follow us: Twitter | Facebook

###

Media Contact

Katie Cottingham

[email protected]