Credit: Francesca De Falco

Wearing clothes can release even greater quantities of microfibres to the environment than washing them, new research shows.

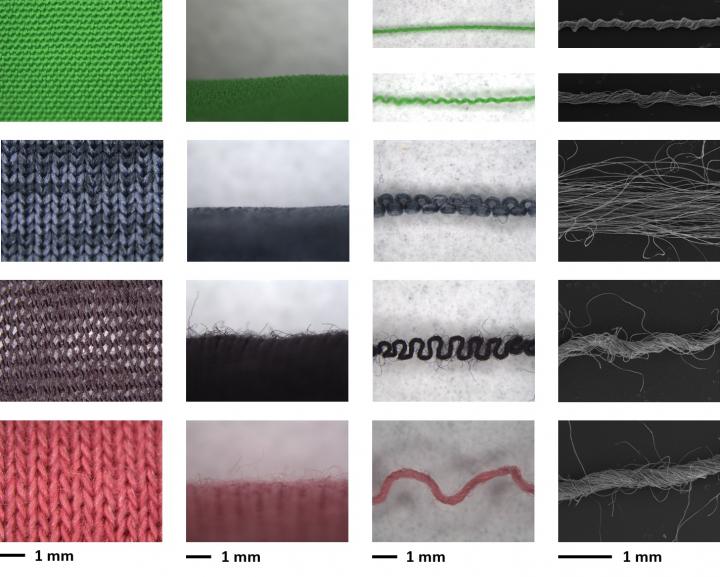

In a first-of-its-kind study, scientists from the Institute for Polymers, Composites and Biomaterials of the National Research Council of Italy (IPCB-CNR) and the University of Plymouth compared four different items of polyester clothing and how many fibres were released when they were being worn and washed.

The results showed that up to 4,000 fibres per gram of fabric could be released during a conventional wash, while up to 400 fibres per gram of fabric could be shed by items of clothing during just 20 minutes of normal activity.

Scaled up, the results indicate that one person could release almost 300million polyester microfibres per year to the environment by washing their clothes, and more than 900million to the air by simply wearing the garments.

In addition, there were significant differences depending on how the garments were made, which the researchers concluding that clothing design and manufacturer has a major role to play in preventing microfibres from being emitted to the environment.

The research, published in the journal Environmental Science and Technology, was conducted by scientists at the National Research Council of Italy and the University of Plymouth. It builds on their previous studies which showed substantial quantities of fibres are released during the laundry process.

Dr Francesca De Falco, Research Fellow at IPCB-CNR and lead author on the current research, said: “Recently, more evidence has been accumulating on the presence of synthetic microfibres not only in aquatic environments, but also in atmospheric ones. That is why we decided to design this set of experiments to study microfibre release by garments to both media. This is a type of pollution that should be mainly fought at its source, the fabric itself, but we investigated the influence of different textile parameters on the release. Results have shown that textiles with a very compact structure like woven, with yarns highly twisted and composed of continuous filaments, can release less microfibres to both air and water.”

The study compared four different garments, which were washed at 40°C with any released fibres being collected. It showed that anywhere between 700 and 4,000 individual fibres could be released per gram of fabric during a single wash.

The researchers also created a dedicated clean lab used by multiple volunteers wearing each of the four garments separately and then performing a sequence of movements simulating a mix of real life activities. Any fibres emitted by the garments were then collected, with up to 400 being released per gram of fabric in just 20 minutes.

The polyester/cotton garment showed the greatest release during both washing and wearing, with a woven polyester one releasing the least quantity of microfibres.

However, based on the overall results, the researchers say previous estimations of microplastic pollution have actually underestimated the importance of synthetic textiles since they did not take into account the quantities released directly into the air.

Professor Richard Thompson OBE, Head of the University of Plymouth’s International Marine Litter Research Unit, was a senior author on the current study and gave evidence to both the UK Government’s Sustainability of the Fashion Industry inquiry and the recent OECD Forum on due diligence in the garment and footwear sector.

He added: “The key story here is that the emission of fibres while wearing clothes is likely of a similar order of magnitude as that from washing them. That constitutes a substantial and previously unquantified direct release to the environment. The results also show textile design can strongly influence both release to the air and release due to laundering; that is a crucial message highlighting the importance of sustainable design for the fashion industry. Indeed many of the current issues associated with the environmental impacts of plastic items stem from a lack of holistic thinking at the design stage.”

###

Media Contact

Alan Williams

[email protected]

0044-175-258-8004

Related Journal Article

http://dx.