Credit: by Haoyi Yu, Haibo Ding, Qiming Zhang, Zhongze Gu, and Min Gu

Three-dimensional (3D) direct laser writing (DLW) based on two-photon polymerisation (TPP) is an advanced technology for fabricating precise 3D hydrogel micro- and nanostructures for applications in biomedical engineering. Particularly, the use of visible lasers for the 3D DLW of hydrogels is advantageous because it enables high fabrication resolution and promotes wound healing. Polyethylene glycol diacrylate (PEGda) has been widely used in TPP fabrication owing to its high biocompatibility. However, the high laser power required in the 3D DLW of PEGda microstructures using a visible laser in a high-water-content environment limits its applications to only those below the biological laser power safety level.

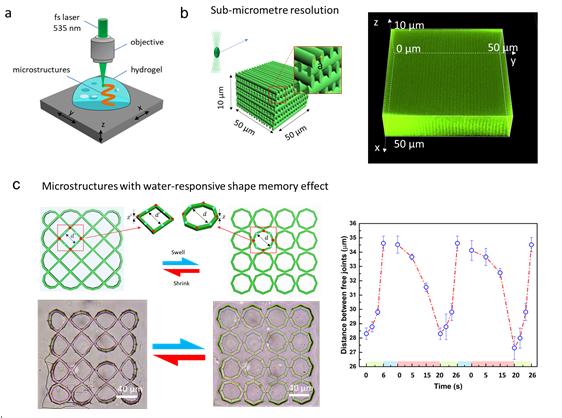

In a new paper published in Light Advanced Manufacturing, a team of scientists, led by Professor Min Gu from from the Centre for Artificial-Intelligence Nanophotonics, University of Shanghai for Science and Technology,and the State Key Laboratory of Bioelectronics, Southeast University, China, and co-workers from the Laboratory of Artificial-Intelligence Nanophotonics, RMIT University, Australia, have developed a formula for a TPP hydrogel based on 2-hydroxy-2-methylpropiophenone (HMPP) and PEGda was developed for the fabrication of 3D DLW microstructures at a low threshold power (0.1 nJ per laser pulse at a writing speed of 10 μm·s?1) in a high-water-content environment (up to 79%) using a green laser beam (535 nm).

Based on these outstanding properties of this hydrogel formula, a novel shape-memory microstructure ‘octagons to squares’ was designed and fabricated in a highwater content environment. Due to the responsive effect of hydrogel to water, the the microstructure can change its shape along with the water content change in the micro-environment. Besides, the microstructure also demonstrated a very robust reversibility. The hydrogel formula and the shape-memory microstructure can support various kinds of applications in biomedical engineering. These scientists summarize the principle that the new photosensitive material is developed upon:

“PEGda is a very typical hydrogel materials and have been widely used in numerous applications in biomedical engineering, due to its high biocompatibility and nontoxicity to biological tissues. The photo initiator: 2-hydroxy-2-methylpropiophenone (HMPP) is one kind of very commonly used photo-initiator for single photon ultra-violet light lithgraphy but has not been used for visible light sources (green) in TPP based on 3D DLW. We chose this material because it can satisfy the needs for future 3D DLW: (1) sub-micrometre fabrication resolution; (2) strong mechanical stability; (3) high polymerization ratio in high water content environment, which will reduce the laser threshold power needed for TPP fabrication; and (4) supports visible light wavelength as the working laser source.”

“The presented material can be used to fabricate various microstructures using 3D DLW with a low power. And it will be used in a wide range of application scenarios, for instance, we can fabricate microstructures with biological tissue on site, and then control shapes of the microstructure using the shape-memory effect. This breakthrough could open a new venue for future reversible microstructures in controlling biological tissues and would be a useful platform for scientists to study the behaviors and functions of biological tissues.” the scientists forecast.

###

Media Contact

Haoyi Yu

[email protected]

Related Journal Article

http://dx.