Scientists develop a method to better manipulate tiny droplets in lab-on-a-chip applications for biochemistry, cell culturing, and drug screening

Credit: Ritsumeikan University, Japan

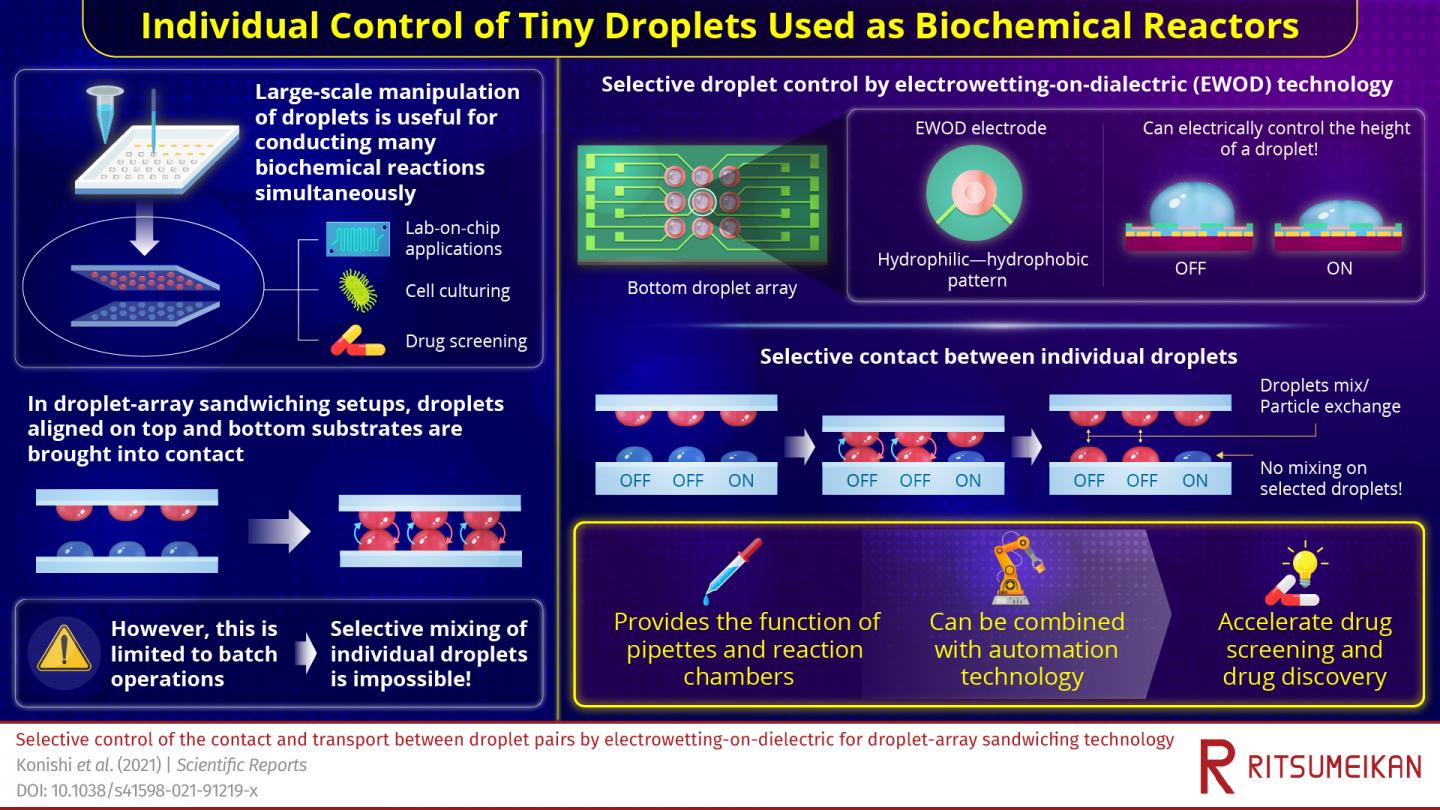

Miniaturization is rapidly reshaping the field of biochemistry, with emerging technologies such as microfluidics and “lab-on-a-chip” devices taking the world by storm. Chemical reactions that were normally conducted in flasks and tubes can now be carried out within tiny water droplets not larger than a few millionths of a liter. Particularly, in droplet-array sandwiching techniques, such tiny droplets are orderly laid out on two parallel flat surfaces opposite to each other. By bringing the top surface close enough to the bottom one, each top droplet makes contact with the opposite bottom droplet, exchanging chemicals and transferring particles or even cells. In quite a literal way, these droplets can act as small reaction chambers or cell cultures, and they can also fulfill the role of liquid-handling tools such as pipettes but on a much smaller scale.

The problem with droplet-array sandwiching is that there is no individual control of droplets; once the top surface is lowered, each droplet on the bottom surface necessarily makes contact with one on the top surface. In other words, this technology is limited to batch operations, which limits its versatility and makes it costlier. Could there be a simple way to select which droplets should make contact when the surfaces are brought closer together?

Thanks to Professor Satoshi Konishi and his colleagues at Ritsumeikan University, Japan, the answer is a resounding yes! In a recent study published in Scientific Reports, this team of scientists presented a novel technique that allows one to individually select droplets for contact in droplet-array sandwiching. The idea behind their approach is rather straightforward: if we could control the height of individual droplets on the bottom surface to make some stand taller than others, we could bring both surfaces close together such that only those droplets make contact with their counterparts while sparing the rest. How this was actually achieved, however, was a bit trickier.

The researchers had previously attempted to use electricity to control the “wettability” of the dielectric material in the area below each droplet. This approach, known as “electrowetting-on-dielectric (EWOD),” lets one slightly alter the balance of forces that holds a water droplet together when resting on a surface. By applying an electric voltage under the droplet, it is possible to make it spread out slightly, increasing its area and reducing its height. However, the team found that this process was not easily reversible, as droplets would not spontaneously recover their original height once the voltage was turned off.

To tackle this problem, they developed an EWOD electrode with a hydrophilic-hydrophobic pattern. When the electrode is turned on, the previously described process makes the droplet on top of it spread out and become shorter. Conversely, when the electrode is turned off, the outer hydrophobic part of the electrode repels the droplet while the inner hydrophilic part attracts it. This restores the original shape, and height, of the droplet!

The researchers showcased their method by laying out multiple EWOD electrodes on the bottom surface of a droplet-array sandwiching platform. By simply applying voltage to selected electrodes, they could easily choose which pairs of droplets came into contact when the top platform was lowered. In their demonstration, they transferred red dye from the top droplets to only some of the bottom droplets. “Our approach can be used to electrically set up individual contacts between droplets, allowing us to effortlessly control the concentration of chemicals in these droplets or even transfer living cells from one to another,” explains Prof. Konishi.

This study paves the way for the potentially fruitful combination of droplet-handling techniques and automation. “We envision that lab-on-chip technology using droplets will replace conventional manual operations using tools such as pipettes, thereby improving the efficiency of drug screening. In turn, this will accelerate the process of drug discovery,” highlights Prof. Konishi. He adds that culturing cells in hanging droplets, which has been used in the field of cell biology, will also make cell-based evaluation of drugs and chemicals cheaper and faster, representing a valuable tool for biochemistry and cell biology.

Let us hope the fruits of this technology “drop” just around the corner!

###

Reference

Title of original paper: Selective control of the contact and transport between droplet pairs by electrowetting-on-dielectric for droplet-array sandwiching technology

Journal: Scientific Reports

DOI: https:/

About Ritsumeikan University, Japan

An eminent private university located in western Japan, Ritsumeikan University is constantly accelerating its efforts toward being a research-intensive institute. In the fiscal year 2020, Ritsumeikan was ranked third among private universities in terms of both the number and the total amount of Grants-in-Aid for Scientific Research awarded by the Japanese government. It has the distinction of being the first university in Japan to have been rated by QS Stars as a four-star institution, while also receiving a five-star rating in internationalization. It has also performed the best among Japanese private universities in the THE Impact Rankings for two consecutive years.

Website: http://en.

About Professor Satoshi Konishi from Ritsumeikan University, Japan

Satoshi Konishi received a BS, MS, and PhD degrees in Electronics and Electrical Engineering from the University of Tokyo, Japan, in 1991, 1993 and 1996, respectively. He joined Ritsumeikan University in 1996, where he currently serves as Professor and director of the Micro/Nano Mechatronics Laboratory. His study is devoted to microelectromechanical systems (MEMS), covering broad ranges of topics from fundamental to applied fields. His current research focuses on biomedical MEMS, especially multiscale interfaces in biomedical engineering.

Media Contact

Kazuki Kurajo

[email protected]

Original Source

http://en.

Related Journal Article

http://dx.