Credit: SUTD

Droplets or emulsions are widely employed in the fields of drug delivery, chemical analysis, biological assays and material synthesis. Emulsions can be created using a microfluidic device that allows generation of droplets of one phase dispersed in an immiscible phase. Unlike bulk emulsification process, microfluidic devices allow for controlled generation of droplets with high monodispersity.

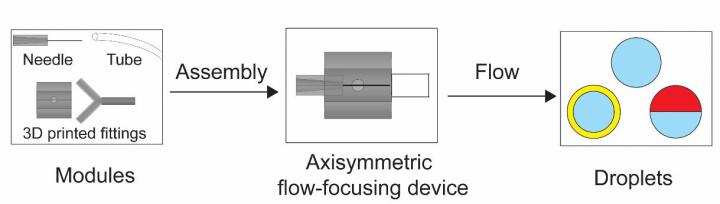

Microfluidic droplet generators are being made by various methods including photolithography, manual assembly of fluidic units and 3D printing. It is challenging to achieve a balance between ease of fabrication of devices and complexity of emulsions produced. Developing a customisable droplet generator that can produce emulsions of varying size and complexity is of great interest. Such devices can be employed for different applications to produce custom-made emulsions. To this end, researchers from the Singapore University of Technology and Design (SUTD) developed a modular approach to fabricate microfluidic axisymmetric droplet generators with distinct modules of 3D printed fittings, needles and tubes.

A single device was made by co-axially aligning a 3D printed connector and needle secured by elastic tubes. The plug-and-play fabrication of these devices allowed for facile reconfiguration and customisation. Each module of the device can be individually altered, and additional modules can be easily attached to vary the type of emulsions. Droplets of varying diameters can be produced by switching the needles attached to the device, and the researchers have achieved a minimum diameter of 332 ± 10 μm for the needle of standard inner diameter of 60 μm. The devices were extended in serial and parallel directions by using appropriate fittings that produced double emulsions and Janus particles.

“By using simple fittings and low-cost units, we were able to rapidly prototype the device in a plug-and -play way. We demonstrated the customisability of the devices by producing simple and complex emulsions by assembling multiple modules together,” said SUTD Assistant Professor Michinao Hashimoto.

This work has been published in RSC Advances, an esteemed journal that encourages high quality multi-disciplinary research. Sindhu Vijayan, a graduate student at SUTD also participated in this research project.

###

Media Contact

Melissa Koh

[email protected]

65-649-98742

Related Journal Article

http://dx.