Credit: Hyung Joon Cha (POSTECH)

As the COVID-19 pandemic spreads around the world, masks have become an essential personal hygiene product as the first line of defense to protect one’s respiratory system against the viruses and germs that spread through droplets in the air. It’s a waste to dispose the masks after single use but troubling to reuse them. In light of this, a Korea-Japan research team recently released findings that compare and analyze the performance and functional differences of the filters used in masks after they are cleaned with ethanol.

Professor Hyung Joon Cha and doctoral candidates Jaeyun Lee and Yeonsu Jeong of the Department of Chemical Engineering at POSTECH and Professor Ick-Soo Kim and doctoral candidates Sana Ullah and Azeem Ullah of Shinshu University in Japan have been jointly analyzing the filtration efficiency, airflow rate, surface and morphological properties of the mask filters after they undergo cleaning treatments.

The research team verified the results using two types of cleaning procedures: First one was spraying 75% ethanol on the mask filter then air drying it, second was to saturate the filter in a 75% ethanol solution then air drying it.

A study of the melt-blown filters commonly used in N95 masks and the nanofiber filters produced by electrospinning found that just by spraying ethanol three or more times on the two materials or dipping them in the ethanol solution for more than five minutes effectively inhibit pathogens that can remain inside the mask filter.

The filtration efficiency of both materials in its first usage was measured at 95% and above, indicating that the wearer’s respiratory system is effectively protected. It was also confirmed that surface of both materials do not allow water to adhere well, sufficiently hindering wetting by moisture or saliva (droplets).

However, the filtration efficiency of the melt-blown filter decreased by up to 64% when cleaned with ethanol solution and reused. On the other hand, the filtration efficiency of nanofiber filters when reused 10 times through ethanol spray cleaning or immersion in ethanol solution for 24 hours maintained nearly consistent high filtration efficiency.

The joint research team attributed this difference to the decrease in static electricity in the filters after cleaning. Melt-blown filters rely in part on the electrostatic effect of the surface when filtering particles. However, nanofiber does not rely on static electricity but filters according to the morphological properties and pore size of the surface, and is not deformed by ethanol.

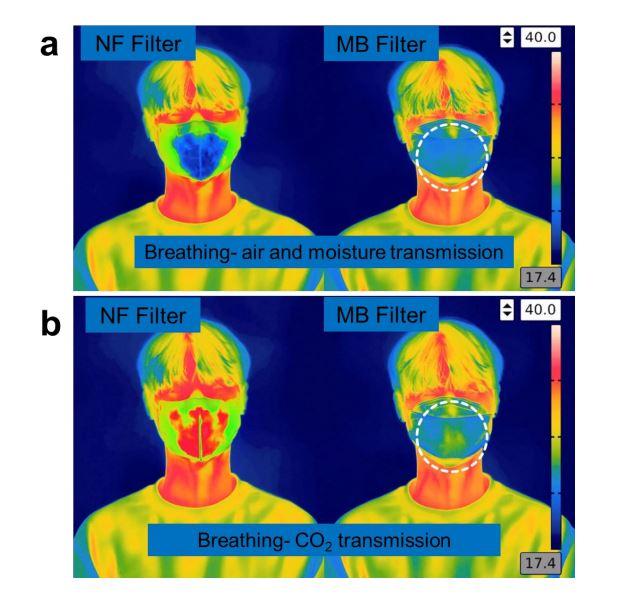

Moreover, nanofiber filters have better breathability because they have much higher heat and carbon dioxide emission capabilities compared to the melt-blown filters. Biosafety tests using human skin and vascular cells also confirmed no cytotoxicity.

In summary, both mask filters have similar filtration performance in its initial use, but only nanofiber filters can be reused multiple times through a simple ethanol cleaning process.

POSTECH Professor Hyung Joon Cha explained the significance of the research by commenting, “This research is an experiment that has verified the biosafety of nanofiber masks – which have recently become a hot issue – and their ability to maintain filtration efficiency after cleaning.”

In addition, Professor Ick-Soo Kim of Shinshu University added, “I hope the nanofiber masks will help everyone as a means of preventing contagion in the possible second or third wave of COVID-19.

###

These research findings were recently published online in the international journal ACS Applied Nano Materials published by the American Chemical Society.

Media Contact

Jinyoung Huh

[email protected]

Original Source

http://postech.

Related Journal Article

http://dx.