In a groundbreaking advance for food technology and pharmaceutical manufacturing, researchers at the University of Arkansas have unveiled a novel 3D-printable bioink derived from sorghum proteins. This innovation leverages the unique hydrophobic properties of sorghum—a drought-resilient grain known for its remarkable adaptability to diverse climatic conditions—to create highly stable and printable gels suitable for producing precise, structured edible and medicinal products. Unlike conventional protein-based printing materials, which are typically hydrophilic and prone to water absorption that compromises print fidelity, sorghum protein’s natural water-repellent nature facilitates improved cohesion and integrity of printed items, addressing a pivotal challenge in the emerging field of 3D food printing.

Sorghum’s robust biological profile is well-established within agricultural and nutritional sciences. This drought-tolerant cereal grain thrives where water scarcity limits the cultivation of other staples, making it an increasingly vital crop amid global climate challenges. Beyond its agronomic advantages, sorghum contains bioactive phenolic compounds with demonstrated antioxidant capabilities, anti-inflammatory effects, and cardiovascular benefits, providing multifaceted value not only as a food source but also as a functional ingredient in health-oriented products. Significantly, sorghum is gluten-free, expanding its relevance for consumers with dietary sensitivities or specific nutritional needs.

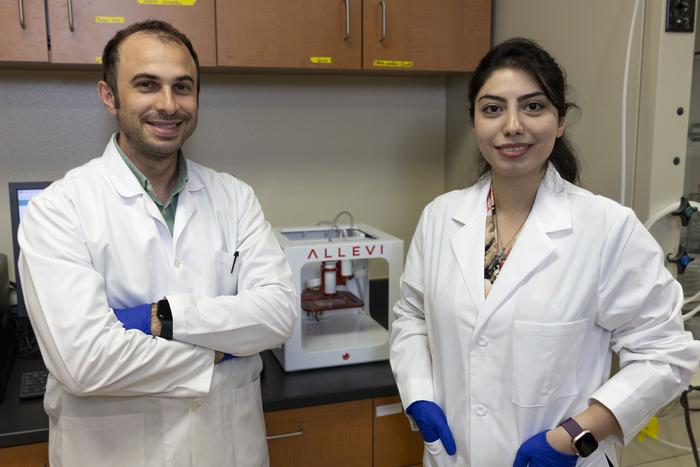

At the heart of this research, Ali Ubeyitogullari, assistant professor of food engineering, has pioneered efforts to refine sorghum proteins for application in 3D printing, focusing on their physicochemical properties to optimize gel formation. Past studies from his laboratory established that sorghum flour itself could serve as a precursor material for 3D-printed edible goods such as cookies, setting the stage for more complex bioink development. Building on these findings, the current work elucidates how protein concentration and printing parameters interact to maximize the printability and structural stability of sorghum protein gels.

.adsslot_8bJa0BdyHL{width:728px !important;height:90px !important;}

@media(max-width:1199px){ .adsslot_8bJa0BdyHL{width:468px !important;height:60px !important;}

}

@media(max-width:767px){ .adsslot_8bJa0BdyHL{width:320px !important;height:50px !important;}

}

ADVERTISEMENT

The team discovered that a protein concentration of 25 percent within the gel formulation yields superior print quality when extruded at a velocity of 20 millimeters per second through a 0.64-millimeter nozzle. Contrary to initial assumptions, elevating the protein concentration to 35 percent did not confer further improvements and, in some cases, impeded printability. These insights underscore the nuanced balance required between composition and printing dynamics to harness the full potential of sorghum proteins as bioinks.

Unlike many plant proteins routinely used in food printing—commonly soy or wheat—which are hydrophilic and thus less compatible with hydrophobic bioactive compounds, sorghum proteins’ water-repelling nature makes them uniquely suited for encapsulating hydrophobic molecules. This capability opens exciting avenues for the food industry and pharmaceutical sector alike, enabling the encapsulation and targeted delivery of water-insoluble nutrients and drugs within stable, biocompatible printed structures.

Sorour Barekat, a postdoctoral fellow and lead author of the study, demonstrated that the sorghum protein-based gels maintain their integrity post-printing, a critical criterion for practical application. The gels’ rheological characteristics—which include viscosity, shear thinning behavior, and viscoelasticity—were meticulously optimized through the use of a rheometer, allowing precise characterization of flow properties essential for extrusion-based 3D printing. This methodological rigor marks a significant stride in establishing sorghum protein as a viable bioink.

The research extends beyond mere food production. Given the gels’ ability to serve as carriers for bioactive hydrophobic compounds, they present a promising vehicle for pharmaceutical encapsulation and controlled release. This dual functionality—edible and medicinal—augments the versatility of 3D printing technology and sets the stage for personalized nutrition and precision medicine, domains poised for transformative growth in the coming decade.

Moreover, this breakthrough aligns with sustainable and economic imperatives. Sorghum’s widespread cultivation in regions vulnerable to climate variability translates into a readily available, cost-effective protein source. Utilizing sorghum proteins in additive manufacturing taps into a renewable resource, promoting circularity and reducing reliance on animal-based proteins, whose production often entails significant environmental footprints.

The publication, appearing in the International Journal of Biological Macromolecules, represents a collaborative endeavor supported by the United Sorghum Checkoff Program, the U.S. Department of Agriculture’s National Institute of Food and Agriculture, and the Arkansas Biosciences Institute. This multidisciplinary support underscores the research’s significance within agricultural innovation, food science, and bioengineering.

Beyond this seminal work, Ubeyitogullari’s lab continues to push the boundaries of 3D food printing. Recent investigations include encapsulating fragile compounds such as lutein within multilayered gel matrices to enhance stability and bioaccessibility, achievements published in journals such as Additive Manufacturing and the Journal of Food Engineering. These complementary studies further elucidate the promise of extrusion-based printing in creating fortified functional foods tailored to consumer health demands.

As global populations grapple with nutritional challenges and resource scarcity, the fusion of advanced materials science and food technology heralds a new era in both nutrition and medicine. The work on sorghum protein bioinks not only exemplifies this convergence but also paves the way toward customizable, on-demand manufacturing of foods and pharmaceuticals that meet specific health and dietary needs.

The potential societal benefits of this technology are vast, from producing safer, allergen-free foods to enabling localized production of pharmaceuticals in remote or resource-limited settings. As 3D printing technology matures, the integration of sustainable, high-performance bioinks like those derived from sorghum will be pivotal in fulfilling the promise of personalized, accessible, and environmentally responsible products.

In sum, the University of Arkansas team’s contribution marks a significant leap forward in additive manufacturing, combining deep molecular understanding of sorghum proteins with cutting-edge engineering to create a novel bioink platform. This work points toward a future where complex nutrient- and drug-loaded materials can be precisely fabricated, transforming both the food landscape and pharmaceutical delivery paradigms.

Subject of Research: 3D-printable bioinks developed from sorghum proteins for food and pharmaceutical applications.

Article Title: Maximizing sorghum proteins printability: Optimizing gel formulation and 3D-printing parameters to develop a novel bioink.

News Publication Date: April 15, 2025.

Web References:

University of Arkansas Agricultural Experiment Station

International Journal of Biological Macromolecules DOI Link

References:

Barekat-Sorghum et al., “Maximizing sorghum proteins printability: Optimizing gel formulation and 3D-printing parameters to develop a novel bioink,” International Journal of Biological Macromolecules, 2025.

Image Credits: University of Arkansas System Division of Agriculture photo by Paden Johnson.

Keywords: Applied sciences and engineering, Food additives, Food chemistry, Agriculture, Foods, Food industry, Plants.

Tags: 3D food printing technologyantioxidant properties of sorghumbioink derived from sorghumclimate-resilient cropsdrought-resilient grainsgluten-free food innovationshealth-oriented food ingredientshydrophobic properties of proteinsnutritional benefits of sorghumpharmaceutical manufacturing advancementssorghum protein bioinkstability in 3D printing