Compound may magnetically outperform neodymium magnets

Credit: NIMS

NIMS and Tohoku Gakuin University have developed a boron-doped anisotropic Sm(Fe0.8Co0.2)12 thin film containing only small amount of rare earth elements. The compound exhibited 1.2 tesla coercivity, sufficient for use in automotive electric motors. This was achieved by creating a unique granular nanostructure in which Sm(Fe0.8Co0.2)12 grains are uniformly enveloped by an amorphous grain boundary phase approximately 3 nm in thickness. This compound exhibited superior magnetic properties to that of Nd-Fe-B based magnets even when processed into a thin film.

Demand for green technologies that can help to reduce CO2 emissions (e.g., electric motors for environmentally friendly vehicles and wind power generation) has been growing, leading to rapidly increasing demand for the high-performance permanent magnets needed for these technologies. The Nd-Fe-B based sintered magnets currently in use are composed not only of the rare earth element neodymium but also a heavy rare earth element: dysprosium. Because of the geopolitical risks associated with the acquisition of these materials, development of new magnets that do not rely on the scarce elements is desirable. Anisotropic SmFe12-based compounds containing relatively small quantities of rare earth elements have been studied for their potential to serve as an effective alternative candidate for the next generation permanent magnets. In 2017, NIMS confirmed that samarium-iron-cobalt compounds (Sm(Fe0.8Co0.2)12) are superior to neodymium magnets in terms of several important magnetic parameters: magnetization, magnetocrystalline anisotropy and Curie temperature. However, previous studies had found these compounds’ coercivity–another important parameter for practical magnets–to be inadequate.

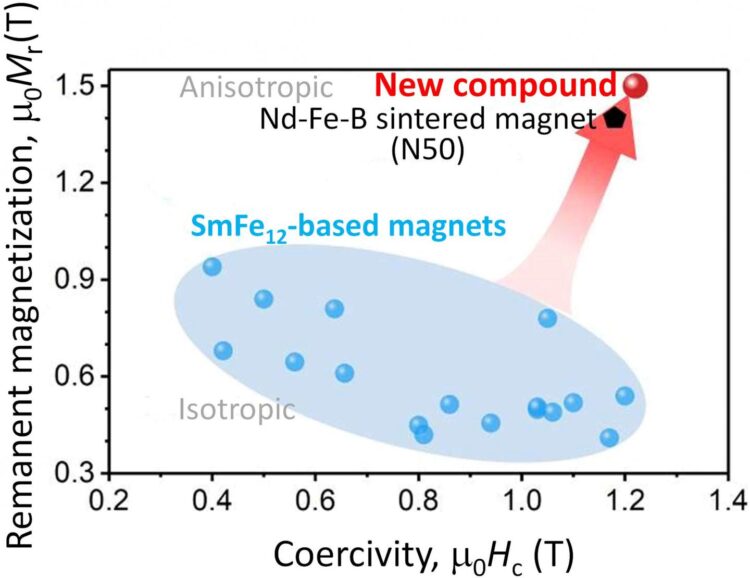

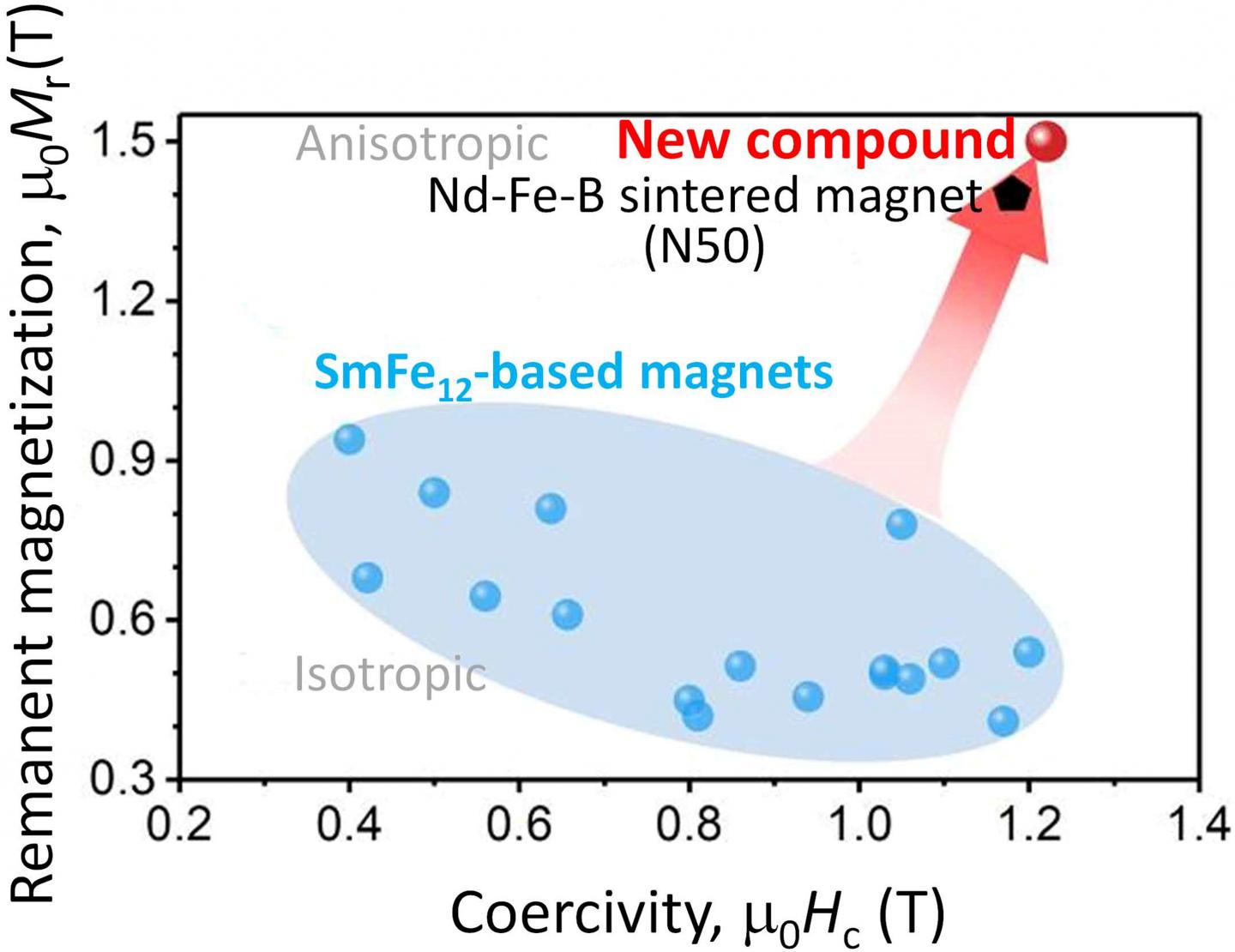

This research group focused on the fact that high-performance neodymium magnets with high coercivity have a multiphase microstructure in which Nd2Fe14B microcrystals are arranged in one direction and individually enveloped by an amorphous phase approximately 3 nm in thickness. The group then attempted to develop a similar microstructure in which individual Sm(Fe0.8Co0.2)12 grains are uniformly enclosed by a thin layer of an amorphous phase. In this research project, the group doped Sm(Fe0.8Co0.2)12 with boron, thereby fabricating a nano-granular microstructure in which Sm(Fe0.8Co0.2)12 nanoparticles are evenly surrounded by an amorphous phase approximately 3 nm in thickness. Moreover, this compound has an anisotropic granular microstructure, enabling it to exhibit a remnant magnetization greater than that exhibited by other SmFe12-based compounds with isotropic granular microstructures. As result, this compound exhibited a large coercivity of 1.2 T combined with a large remanent magnetization of 1.5 T, much larger than the previously developed SmFe12-based magnetic compounds.

This Sm(Fe0.8Co0.2)12 compound with an anisotropic, multiphase microstructure was proven to have very high coercivity, even when processed into a thin film. It may serve as a novel magnet capable of outperforming neodymium magnets. Previously studied anisotropic Sm(Fe0.8Co0.2)12 compounds exhibited significantly lower coercivity than the compound developed in this research. The underlying mechanisms which lead to realizing a high coercivity discovered in this research may be applicable to bulk magnets with the aim of developing practical anisotropic Sm(Fe0.8Co0.2)12 magnets with high coercivity.

###

This project was carried out by a research group led by H. Sepehri-Amin (NIMS Principal Researcher) and Toshiyuki Shima (Professor, Tohoku Gakuin University) and supported by MEXT-funded Elements Strategy Initiative Center for Magnetic Materials (ESICMM). This research was published in the online version of Acta Materialia on June 12, 2020.

Contacts

(Regarding this research)

H. Sepehri-Amin

Research Center for Magnetic and Spintronic Materials

National Institute for Materials Science (NIMS)

Tel: +81-29-859-2739

E-Mail: [email protected] =nims.go.jp

(Please change “=” to “@”)

Toshiyuki Shima

Professor, Department of Engineering

Tohoku Gakuin University

Tel: +81-22-368-1128

E-Mail: shima=mail.tohoku-gakuin.ac.jp

(Please change “=” to “@”)

(General information)

Public Relations Office

National Institute for Materials Science

Tel: +81-29-859-2026, Fax: +81-29-859-2017

Email: pressrelease=ml.nims.go.jp

(Please change “=” to “@”)

Public Relations Office,

Public Relations Department,

Tohoku Gakuin University

Tel: +81-22-264-6423, Fax: +81-22-264-6478

Email: koho=mail.tohoku-gakuin.ac.jp

(Please change “=” to “@”)

Media Contact

Yasufumi Nakamichi

[email protected]

Original Source

https:/

Related Journal Article

http://dx.