Credit: POSTECH

Plastic is light, cheap, and can be made into any shape if heated, making it a “gift from the 20th-century god.” The key is to maintain its uniform quality but its sensitivity to process conditions makes processing autonomy difficult. It also takes long to change the process once it is set and real-time optimization is deemed impossible due to the difference in actual outcomes.

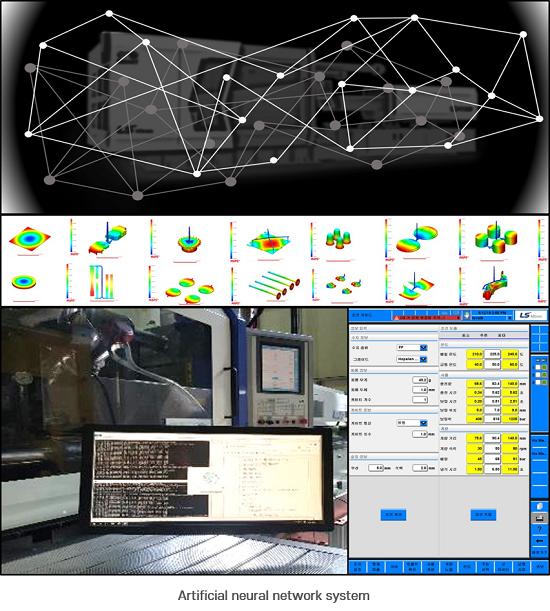

A research team consisting of Professor Junsuk Rho and doctoral student Chihun Lee of POSTECH’s departments of mechanical and chemical engineering and Professor Seungchul Lee, Juwon Na in the MS-PhD integrated program with Professor Seongjin Park in the Department of Mechanical Engineering have together developed a system that recommends process conditions for injection molding by combining artificial neural network (Artificial Neural Network) and a random search. Various shapes can be obtained in real time through using this new system. These research findings were recently published in the journal Advanced Intelligent Systems.

The team trained the relationship between process conditions and final products using artificial intelligence to find the conditions that satisfy the target quality. 3,600 simulations and 476 experiments from 36 different molds were obtained and learned. As a result, the team confirmed that each datum had 15 shapes and five processes as input value and the final weight of the product as the output value.

Based on the weight prediction model trained through transfer learning, a recommender system was developed to find the optimal process conditions by random search. By applying the conditions recommended by the AI model, the average relative error of 0.66% was achieved.

Finally, a GUI (graphical user interface) was developed for the actual injection machines. This allows even non-experts to enter the shape information for any product to establish a process condition that has an error within 1% of the target product weight.

Conventional research predicted the quality of the target product by only changing the process conditions for one specified product. However, this study collected information on the results (weight) of 36 differently shaped products while changing both quantified shapes and process conditions. Therefore, even if a new product is molded, the process conditions can be controlled without having to predict the results or to generate learning data by simply entering the shape of the product. In addition, transfer learning was introduced to obtain both simulation data and the accuracy of experimental data.

Using this newly developed artificial neural network system, even non-experts can obtain uniform results by simply entering the shape and the weight of the final product desired. It is anticipated that such system will enable the implementation of ‘unmanned smart factory’ in various manufacturing industries by allowing plastic injection processes, machining, 3D printers, and casting, which were previously challenging.

###

This research was jointly conducted with LS Mtron, the Korea Institute of Industrial Technology, VM Tech and POSCO, and supported by the Ministry of Science and ICT and the National Research Foundation of Korea (Mid-career Researcher program, Global Frontier Project, RLRC Leading Research Center), the Ministry of Trade, Industry and Energy-Korea Evaluation Institute of Industrial Technology (Machine Industry Core Technology Development Program).

Media Contact

Jinyoung Huh

[email protected]

Original Source

http://postech.

Related Journal Article

http://dx.