Credit: PENG Shenyou

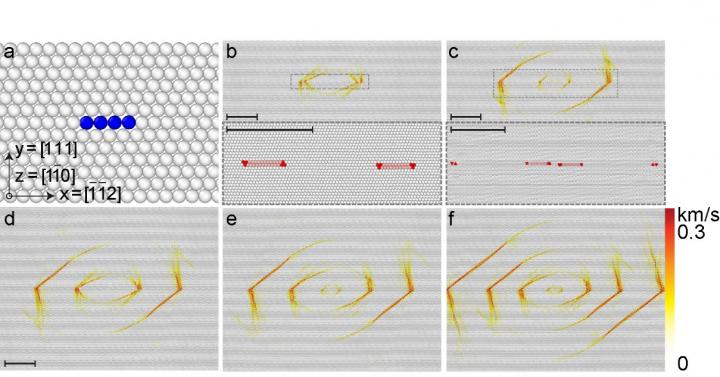

Researchers from the Institute of Mechanics of the Chinese Academy of Sciences, teaming up with scientists from Singapore and the U.S., have found that nanoscale precipitates provide a unique sustainable dislocation source at sufficiently high stress.

The scientists discovered that densely dispersed nanoprecipitates simultaneously serve as dislocation sources and obstacles, leading to a sustainable and self-hardening deformation mechanism that enhances ductility and strength. The results were published in PNAS on Feb. 24, 2020.

In structural materials, resistance against deformation is of vital importance, specifically resistance to the initiation of plastic deformation or yielding; the stress at this point represents the strength of the material. Meanwhile, how much a metal can deform plastically – its ductility – is another important measure. Both strength and ductility depend on the movement of metal dislocations.

Movement of a dislocation becomes more difficult if some barrier or discontinuity enters the path of the dislocation, that is, the materials are hardened. Among many hardening routines, precipitate hardening has been well established and widely employed in engineering materials like Al alloys, Ni super alloys, steel, and recently discovered high-entropy alloys.

Precipitates serve as obstacles to dislocation glide and cause hardening of the material. However, they may lead to premature failure and decreased ductility. Obstacles to dislocation glide often lead to high stress concentration and even microcracks, a cause of progressive strain localization and the origin of the strength-ductility conflict.

According to the researchers, the key to mitigating the conventional strength-ductility tradeoff is to employ a mild yet homogeneous hardening mechanism at a high stress level. Nanoprecipitates provide a sustainable and self-hardening deformation mechanism that enhances ductility and strength. The condition for achieving sustainable dislocation nucleation from a nanoprecipitate is governed by the lattice mismatch between the precipitate and matrix.

Dr. PENG Shenyou, author of the study, said “The interplay of the two length scales, precipitate size and spacing, can be utilized as an optimal design motif to produce a superb combination of strength and ductility, as well as provide a criterion for selecting precipitate size and spacing in material design.”

These findings establish a foundation for strength-ductility optimization through densely dispersed nanoprecipitates in multiple-element alloy systems.

###

The research was support by the National Natural Science Foundation of China and the Strategic Priority Research Program of the Chinese Academy of Sciences.

Media Contact

PENG Shenyou

[email protected]

Related Journal Article

http://dx.