Credit: LI Mingjie and LI Xiankai

Liquid metals (LMs) are promising for applications in flexible electronics and biomimetic functional composites. Nanometerization and surface modification of LMs are usually used to improve their substrate affinity and processing properties. In most cases, LM nanodroplets are encapsulated into ultrathin and fragile shells of oxides or amphiphile monolayers.

However, it may be hindered from being incorporated homogeneously into various composites through conventional processing methods. Therefore, producing stable and processable LM nanodroplets remains challenging.

In their previous study, Prof. LI Chaoxu and his coworkers from the Institute of Bioenergy and Bioprocess Technology (QIBEBT) of the Chinese Academy of Sciences (CAS) revealed that LM can initiate free radical polymerization of vinyl monomer under ultrasonication.

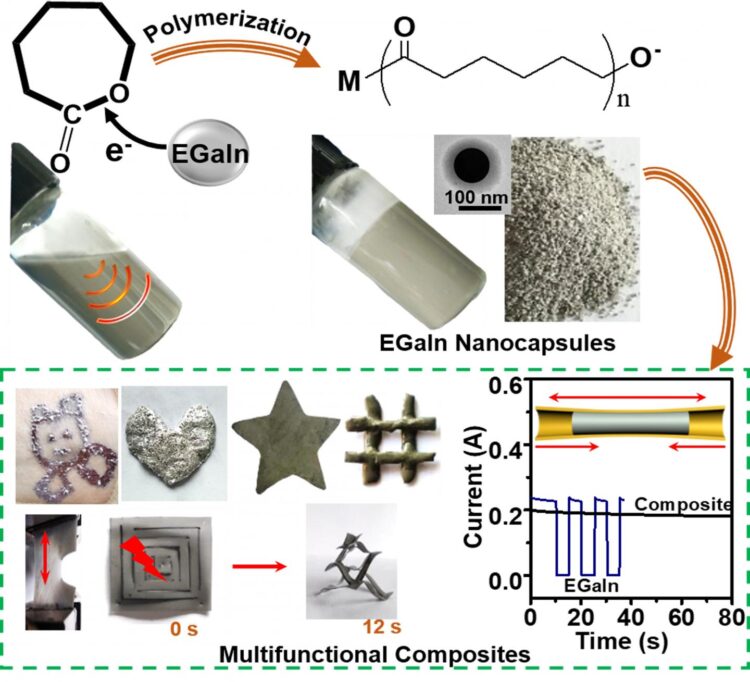

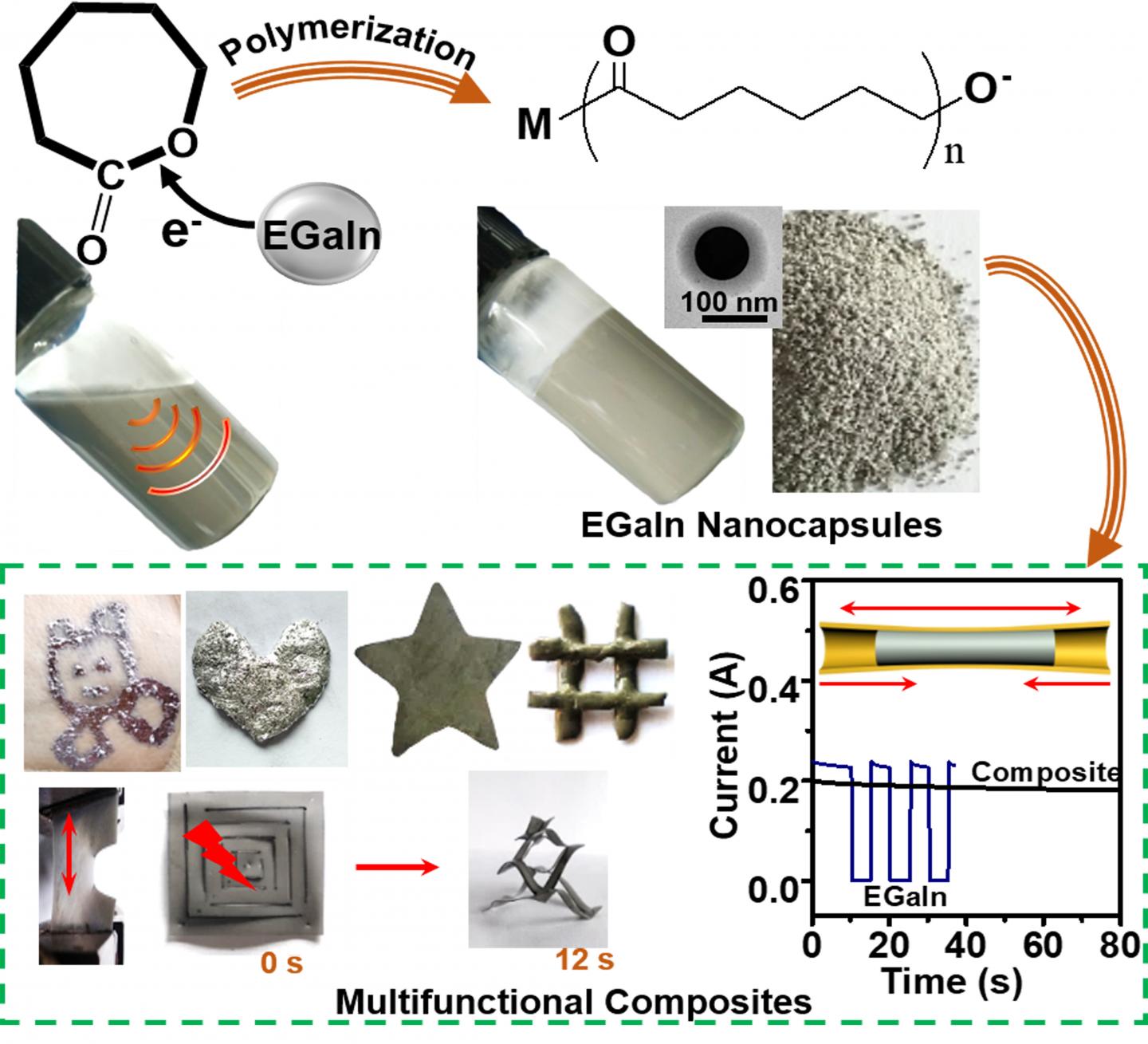

Recently, this research group, for the first time, has found that the ring-opening polymerization was initiated by sonicating liquid metal in fluidic lactones and proposed multifunctional liquid metal nanocapsules. “By this in-situ polymerization, LM nanodroplets were encapsulated into polylactone shells with tunable thickness, which could further be dried into solid powder,” said Prof. LI.

Besides high chemical stability and dispersibility in organic solvents, the powder of LM capsules combined exceptional properties of LM droplets and polylactone shells. It could be introduced into thermoplastic composites through liquid casting and thermal-/photo-molding for notch-insensitive tearing property, sintering-induced electric conductivity and photo-thermal effect.

LM initiator of ring-opening polymerization may start a pathway to produce stable and thermal/photo-moldable powder of LM capsules and their multifunctional composites applicable in biomedicines, soft electronics and smart robots.

###

The study was published in Advanced Materials on Sept. 21. It was supported by the National Natural Science Foundation of China, QIBEBT & Dalian National Laboratory for Clean Energy (DNL), CAS and Shandong Collaborative Innovation Center.

Media Contact

CHENG Jing

[email protected]

Related Journal Article

http://dx.