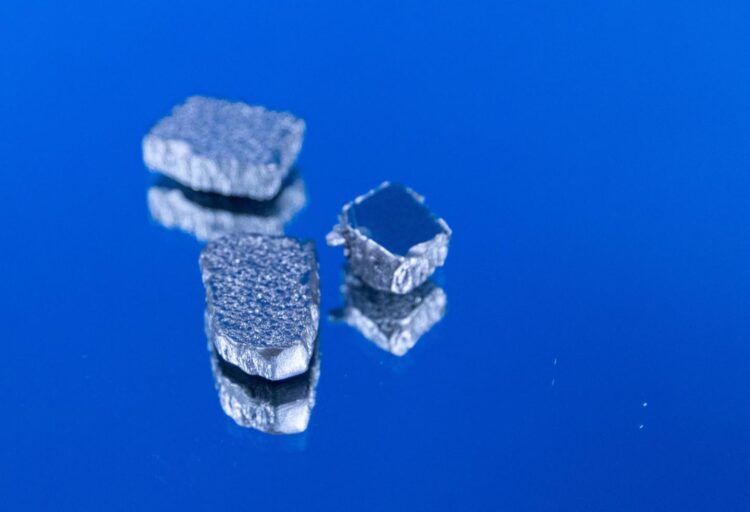

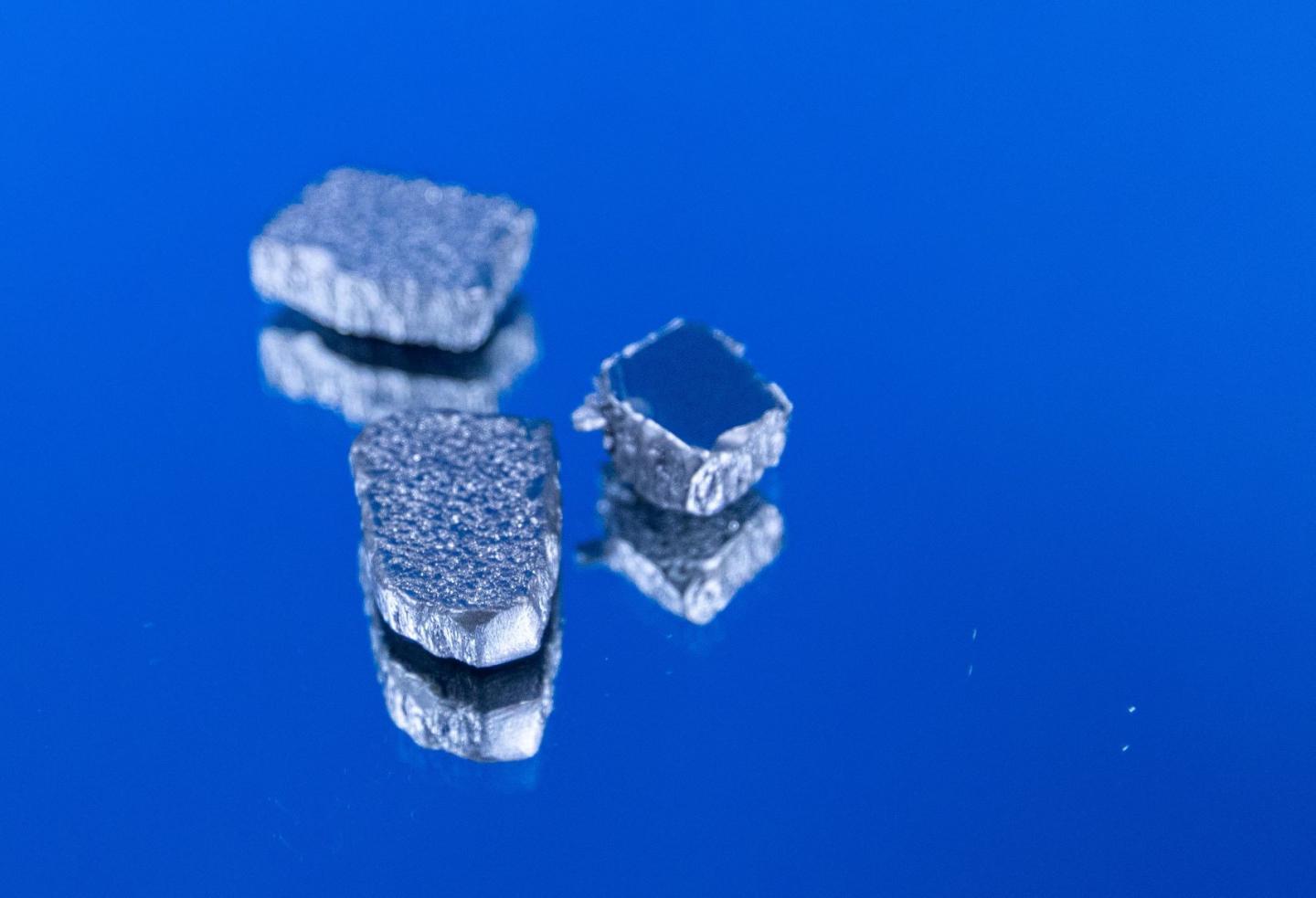

Credit: photo credit: U.S. Department of Energy Ames Laboratory

The U.S. Department of Energy’s (DOE’s) Critical Materials Institute has developed a low-cost, high performance permanent magnet by drawing inspiration from an out-of-this-world source: iron-nickel alloys in meteorites. The magnet rivals widely used “Alnico” magnets in magnetic strength and has the potential to fill a strong demand for rare-earth- and cobalt-free magnets in the market.

Here on earth, the strongest permanent magnets are ones containing the rare earth element neodymium – NdFeB magnets. Next strongest are Samarium-Cobalt, or SmCo magnets. Before rare-earth magnets were developed in the 1970s, the strongest magnets were made of aluminum-nickel-cobalt, or Alnico, which are still in wide use today in applications ranging from electric motors to consumer electronics.

The problem with these strong but earthly man-made permanent magnets is that they contain critical elements– rare earths in the case of NdFeB and SmCo, and cobalt in the case of SmCo and Alnico– ones that are in high demand for many technologies and for which manufacturers pay a premium for a sometimes unreliable supply.

“The iron-nickel magnetic alloys found in meteors are rare-earth and cobalt-free, but are highly ordered and take millions of years to produce through natural means,” said Vitalij Pecharsky, scientist at U.S. DOE’s Ames Laboratory and CMI. “Our team — Oleksandr Dolotko, Ihor Hlova, Shalabh Gupta, and Anis Biswas – developed a method to produce the magnetic qualities of iron-nickel alloys that already perform on the level of Alnico, but in a much faster fashion.”

The method introduces a large number of defects into an iron and nickel alloy. It is then placed in reaction with ammonia, which results in a chemically ordered precursor iron-nickel-nitrogen, or FeNiN. The next step extracts the nitrogen from the material, without disturbing the order of the remaining iron and nickel.

Pecharsky said the ammonia process is scalable and reliably yields the precursor material at about 98 percent. The end product has energy density of 6 MG-Oe, which makes it comparable to Alnico magnets, and room for further improvements is substantial.

“There is a market demand for magnets that fill the gap in technical applications between the higher end, strongest rare-earth permanent magnets, and lower-strength options,” said Pecharsky. “We see this gaining wide adoption in that gap magnet space.”

The Critical Materials Institute is a Department of Energy Innovation Hub led by the U.S. Department of Energy’s Ames Laboratory and supported by the Office of Energy Efficiency and Renewable Energy’s Advanced Manufacturing Office, which supports early-stage applied research to advance innovation in U.S. manufacturing and promote American economic growth and energy security. CMI seeks ways to eliminate and reduce reliance on rare-earth metals and other materials subject to supply chain disruptions.

Ames Laboratory is a U.S. Department of Energy Office of Science national laboratory operated by Iowa State University. Ames Laboratory creates innovative materials, technologies and energy solutions. We use our expertise, unique capabilities and interdisciplinary collaborations to solve global problems.

DOE’s Office of Science is the single largest supporter of basic research in the physical sciences in the United States, and is working to address some of the most pressing challenges of our time. For more information, please visit science.energy.gov.

###

Media Contact

Laura Millsaps

[email protected]

Original Source

https:/