Credit: HUANG Qingshan

Gas-liquid and gas-liquid-solid reactors have been widely applied in fermentation, photosynthetic culture, metallurgy, and many other processes in chemical industries.

Accurate prediction of bubble diameter is crucial for the proper design, optimization, and scale-up of gas-liquid apparatuses. Most previous research focused only on orifice superficial gas velocity Recently, a research team led by Prof. YANG Chao from the Qingdao Institute of Bioenergy and Bioprocess Technology (QIBEBT), Chinese Academy of Sciences (CAS), systematically investigated the influence of orifice diameter, liquid viscosity, surface tension and orifice superficial gas velocity on the bubble diameter of gas spargers under industrial jetting conditions.

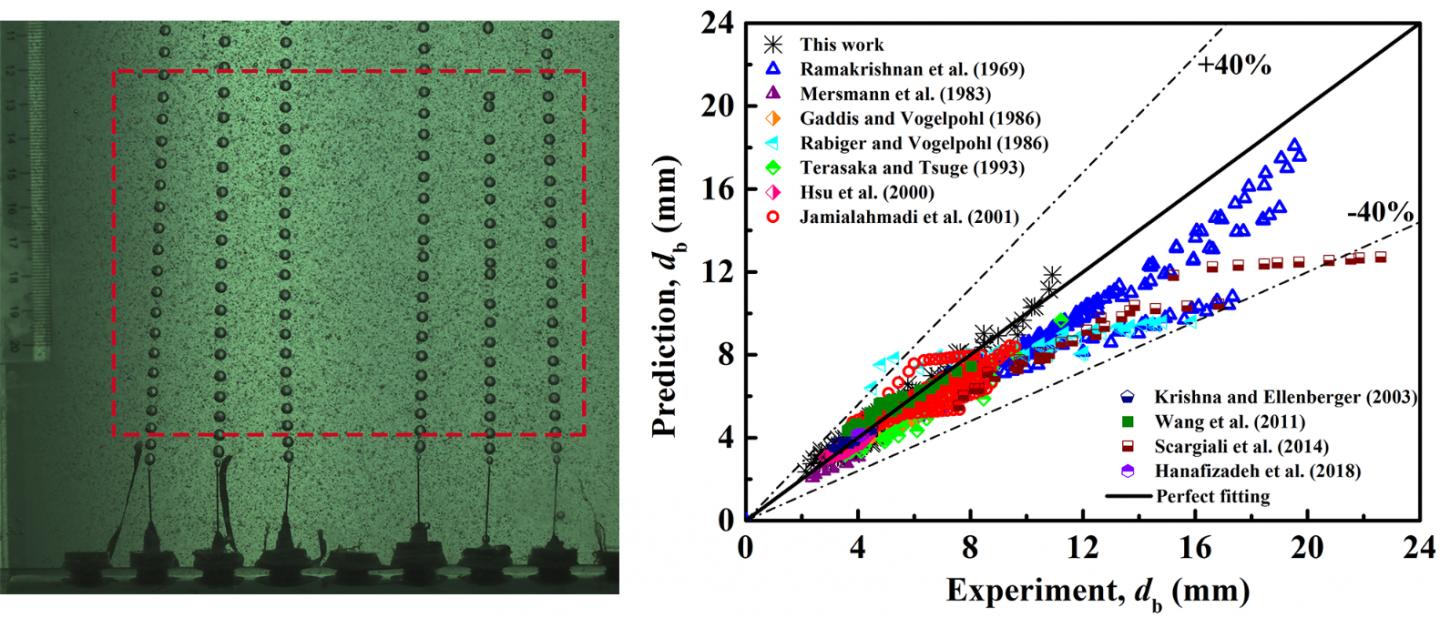

In the study, the bubble diameter was investigated in a rectangular vessel made of transparent Plexiglas. Bubbles were recorded through a single-lens reflex camera. A typical bubble formation image is illustrated in Fig.1 (a). Bubble sizes were analyzed and calculated using patented software (Chinese Software Copyright Registration Number: 2017SR354522).

Based on extensive experimental results, a simple correlation for predicting bubble diameter was proposed using nonlinear least square optimization. The new correlation was successfully validated by comparing prediction results with experimental data over a wide range of operating conditions and working systems from the literature.

The comparison of the results predicted by the new model versus the experimental data from our work and the literature is shown in Fig. 1 (b). Only 6.54% of the 657 experimental results obtained from the literature had deviations of more than 30%, indicating that the proposed correlation in this work can be applied extensively with reasonable accuracy.

These findings were published in Chemical Engineering Science. This work was supported by the National Natural Science Foundation of China, the Instrument Developing Project of CAS, and the “Transformational Technologies for Clean Energy and Demonstration”, Strategic Priority Research Program of CAS.

###

Media Contact

CHENG Jing

[email protected]

Related Journal Article

http://dx.