In a groundbreaking advancement poised to revolutionize the field of on-demand manufacturing and sensing, researchers from Japan’s Shibaura Institute of Technology have developed a palm-sized, portable multimaterial printer capable of fabricating intricate three-dimensional origami devices. Harnessing the power of electrowetting on dielectric (EWOD) technology, this innovative system enables precise, valve-free manipulation and deposition of conductive and insulating inks on flexible substrates such as paper. This technological leap paves the way for rapid, site-specific production of functional Internet of Things (IoT) sensors, bridging the gap between complex fabrication processes and real-world applications in remote or resource-limited environments.

Origami-inspired three-dimensional devices have emerged as a transformative approach to create compact, foldable, and multifunctional systems by transforming a single flat sheet into a complex three-dimensional architecture. These devices are rapidly gaining traction across diverse fields including healthcare, agriculture, and aerospace, where miniaturization, adaptability, and portability are critical. Examples include bioresorbable stents and surgical tools, soil sensors for precision agriculture, and lightweight deployable solar arrays for spacecraft. However, despite the conceptual appeal, the practical fabrication of such devices on-site remains a challenge mainly due to limitations in existing manufacturing platforms that are bulky, complex, or impractical outside laboratory environments.

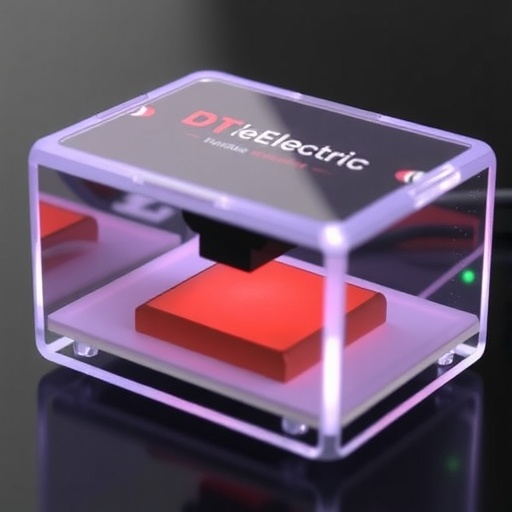

Meeting the increasing demand for customized, on-site fabricated sensors, the multidisciplinary team led by Associate Professor Hiroki Shigemune introduced a novel EWOD-based printing system that functions without conventional pumps or valves. EWOD technology manipulates discrete liquid droplets by modulating their contact angle on a dielectric surface under an applied electric field, enabling digital microfluidic control with unprecedented precision. This sophisticated mechanism facilitates the independent control and deposition of multiple materials, enabling the formation of composite functional structures that are vital for creating integrated origami devices with tailored electrical and mechanical properties.

The compact printer leverages electrical ON/OFF signals to regulate droplets of both conductive and insulating inks, which are selectively printed onto paper substrates to form structural and functional components. Paper, chosen for its flexibility, porosity, and environmental compatibility, serves as an ideal platform for these stretchable and breathable devices. The integration of inkjet-like precision within a portable form factor eliminates the need for bulky external components, making this system especially suitable for decentralized manufacturing, including field deployment in agriculture, emergency medical scenarios, and even extraterrestrial missions where conventional infrastructure is unavailable.

To demonstrate the capabilities of their portable system, the researchers optimized printing parameters separately for structural inks forming device frameworks and electrode inks enabling electrical functionality. Remarkably, when combined, these materials maintained full performance without cross-interference, ensuring device reliability. Among the fabricated prototypes were a stretchable strain sensor and a respiration sensor, both conforming to paper substrates. The strain sensor exhibited remarkable endurance, maintaining stable output after over 1,000 mechanical deformation cycles, while the respiration sensor reliably detected breath patterns through repeated testing, highlighting the robustness and longevity of devices produced via this method.

The durability and flexibility of these origami sensors stem not only from the materials and printing technology but also from the inherent properties of paper-based substrates. Their lightweight and porous nature not only contribute to wearability and comfort when integrated into garments or masks for health monitoring but also enhance environmental sustainability by reducing electronic waste. These characteristics align well with the growing global emphasis on developing eco-friendly, disposable, yet functional electronic systems for the rapidly expanding IoT landscape, especially in sectors requiring mass deployment of sensors with minimal ecological footprint.

One of the primary advantages of this EWOD-enabled portable printer lies in its minimalistic design, comprising mainly paper, functional inks, and a compact electronic control unit. This minimalism drastically reduces the logistical burden of transporting manufacturing equipment, allowing for instant device fabrication in off-grid or challenging environments. For instance, in disaster relief operations where traditional supply chains are disrupted, medical personnel could swiftly fabricate customized sensors or diagnostic tools on-site. Similarly, agricultural workers could produce environment-specific sensors tailored to local conditions, optimizing resource use and crop yields without relying on centralized manufacturing facilities.

Furthermore, the implications of such technology extend beyond Earth. Space missions, which require lightweight and adaptable hardware to optimize payload and respond dynamically to unforeseen challenges, stand to benefit from on-demand fabrication capabilities enabled by this system. The ability to produce sensors or devices tailored to changing mission parameters without the need for extensive storage or resupply could enhance mission safety and efficiency. This aligns with the broader vision of sustainable, flexible manufacturing paradigms that support human exploration and habitation of extraterrestrial environments.

By enabling digital control over multimaterial printing processes without mechanical pumps or valves, the approach simplifies device fabrication workflows and reduces potential points of failure. This innovation is particularly significant in realizing high-throughput yet customizable manufacturing of IoT devices where each sensor might demand unique shapes or functionalities. Such versatility opens avenues in personalized healthcare, where wearable biosensors could be tailored to individual patient needs at the point of care, enhancing monitoring effectiveness while reducing costs and complexity inherent in mass-produced devices.

Associate Professor Hiroki Shigemune and his team foresee this EWOD-based portable printing platform as a foundational tool for smart agriculture and medical IoT applications. On-site fabrication of sensor-integrated smart packaging for harvested fruits, customized to specific size or impact sensitivity, can significantly augment quality control processes. Similarly, producing wearable respiratory or motion sensors compatible with masks and clothing can facilitate real-time infection monitoring and eldercare, offering new layers of proactive healthcare management especially during pandemics or in aging societies.

The system’s scalability and cost-effectiveness also suggest its potential to democratize advanced sensor technology, making it accessible to end-users in diverse contexts worldwide. By eliminating the dependence on centralized manufacturing hubs, it can empower localized innovation and rapid prototyping, catalyzing community-driven technological adoption. The use of common materials such as paper and inks, combined with the absence of complex mechanical systems, promises low barriers to replication and widespread dissemination.

In sum, this novel EWOD-based portable multimaterial printer marks a significant stride toward sustainable, flexible, and accessible manufacturing of functional origami devices. The successful integration of electrical and structural components on flexible substrates, combined with a minimalistic, compact design, opens myriad possibilities across smart sensing, medical devices, agriculture, and space exploration. Dr. Shigemune’s research group has laid the groundwork for a transformative fabrication paradigm that aligns seamlessly with the environmental imperatives and technological aspirations of the modern era.

Subject of Research:

Not applicable

Article Title:

Electrowetting on Dielectric (EWOD) Based Portable Multimaterial Printer To Fabricate Origami Devices

News Publication Date:

30-Jul-2025

Web References:

https://doi.org/10.1021/acsami.5c12629

References:

DOI: 10.1021/acsami.5c12629

Image Credits:

Dr. Hiroki Shigemune from Shibaura Institute of Technology, Japan

Keywords:

Additive manufacturing, Sensors, Wearable devices, Medical technology, Sustainable development, Microfluidics, Materials science, Fabrication

Tags: aerospace lightweight deployable systemscompact multifunctional systemselectrowetting on dielectric applicationsflexible substrate fabrication methodsinnovative healthcare device fabricationInternet of Things sensor productionon-demand manufacturing advancementspalm-sized electrowetting printerportable multimaterial printer technologyprecision agriculture sensor technologyresource-limited manufacturing solutionsthree-dimensional origami devices