Credit: University of Illinois Urbana-Champaign

Researchers at University of Illinois Urbana-Champaign developed software to improve the accuracy of 3D-printed parts, seeking to reduce costs and waste for companies using additive manufacturing to mass produce parts in factories.

“Additive manufacturing is incredibly exciting and offers tremendous benefits, but consistency and accuracy on mass-produced 3D-printed parts can be an issue. As with any production technology, parts built should be as close to identical as possible, whether it is 10 parts or 10 million,” said Professor Bill King, Andersen Chair in the Department of Mechanical Science and Engineering and leader of the project.

The team’s software allows for the rapid and automatic measurement of additively manufactured parts – a processes that is typically time consuming and costly. It also allows for increased accuracy.

“Factories that rely on 3D printing are being built rapidly all over the world. Our software helps ensure production is consistent, accurate, and cost-effective,” King said.

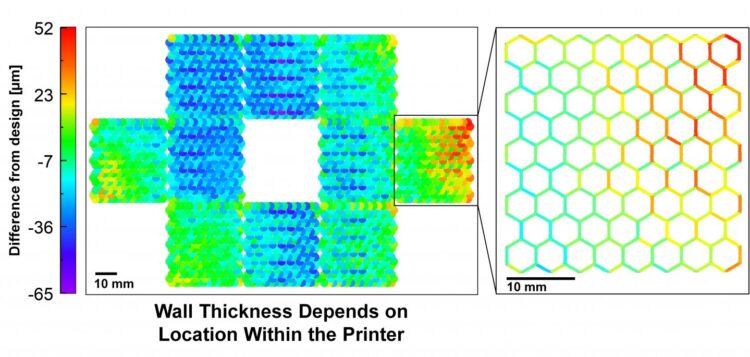

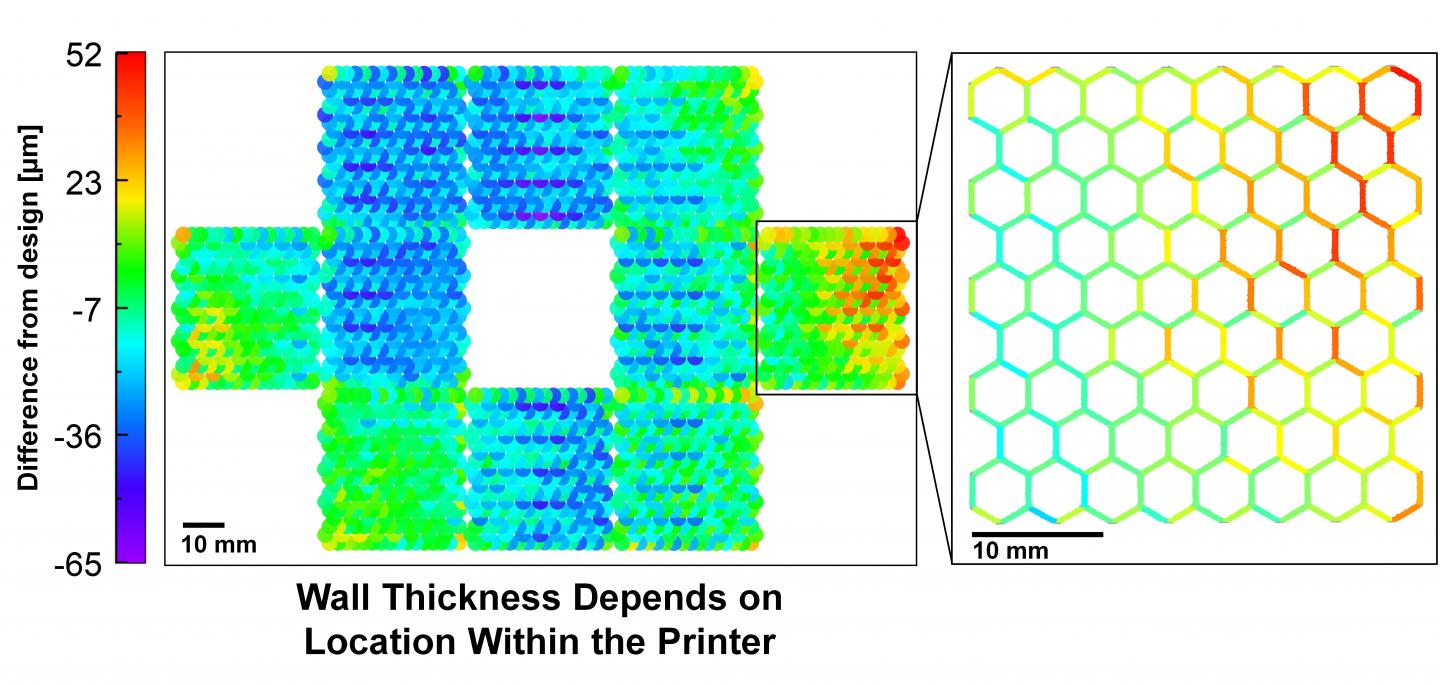

The software tracks how the accuracy of an additively manufactured part depends on which printer made the part and where the part was located in the printer. This process works by measuring parts using optical scanning technology and analysis of the scan data. This analysis allows a user to determine which parts are accurate and identifies which printers, and settings, produce the most accurate parts.

###

The University of Illinois researchers collaborated with engineers at Fast Radius Inc., a Chicago-based company with one of the world’s largest additive manufacturing factories. In 2018, the World Economic Forum identified Fast Radius as one of the world’s most advanced digital factories. King is one of the company’s co-founders and serves as its chief scientist.

The research was published this month in Additive Manufacturing, in an article titled: “Analyzing part accuracy and sources of variability for additively manufactured lattice parts made on multiple printers.” Authors on the study are Davis J. McGregor, Sameh Tawfick, and Chenhui Shao, and William King from University of Illinois, and Samuel Rylowicz, Aaron Brenzel, Daniel Baker, Charles Wood, David Pick, and Hallee Deutchman from Fast Radius.

Media Contact

Bill Bell

[email protected]

Related Journal Article

http://dx.