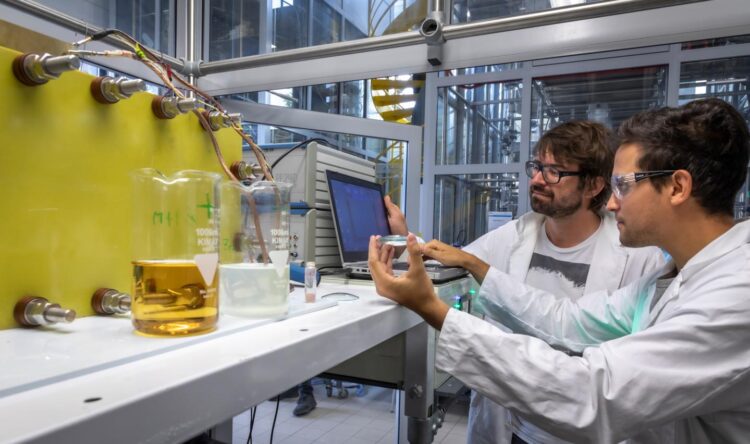

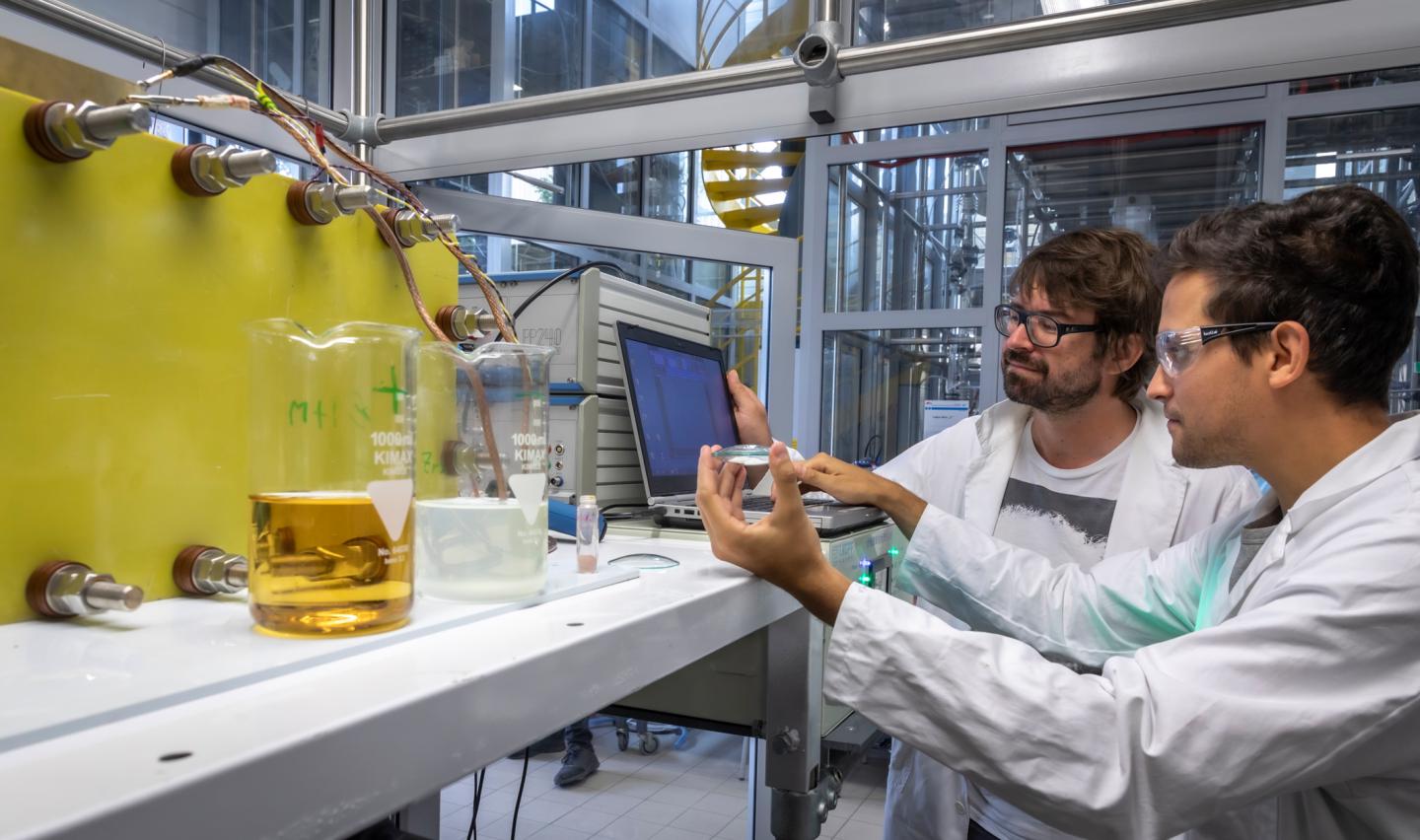

Credit: © Lunghammer – TU Graz

The increasing use of battery technologies in the mobility sector and in stationary applications has been leading to increasing efforts in battery research of operational safety and battery recycling. The group led by Stefan Spirk at the Institute of Bioproducts and Paper Technology at TU Graz is now also devoting itself to these topics. The development of a vanillin-based redox flow battery by Spirk and his team recently caused attention in international press reports. The environmental and safety aspects of these and all currently available redox flow technologies are being investigated in the SABATLE project (Safety assessment of flow battery electrolytes).

Toxicological evaluation and safety tests

Together with the partners BioNanoNet, the Institute of Systems Sciences, Innovation and Sustainability Research at the University of Graz, the company Mondi and the Spanish biotechnology company Biobide, researchers at TU Graz are investigating the safety risks for humans and the environment posed by redox flow technologies. “We consider exposure scenarios for accidents that may occur during and after the use of such batteries. We also want to find out what toxic doses people and the environment are realistically exposed to in such accidents,” says Spirk.

Redox flow technology is important for the expansion of renewable energies such as wind and solar power, as it is characterized by the storage of large amounts of energy and can therefore mitigate voltage peaks in the power grid. The batteries are also suitable as backup storage for stationary applications such as power plants, hospitals, mobile phone systems or e-fuelling stations. “We want to carry out a benchmarking study that identifies risk factors and highlights potential for improvement in this area,” continued Spirk.

Thus, another core element of the project is the further development of such redox flow systems according to the Safe-and-Sustainable-by-Design (SaSbD) concept, a core competence of the Graz-based research company BioNanoNet. Its CEO Andreas Falk names the advantages of SaSbD: “By implementing this concept, potential risks are mitigated and avoided, and this ultimately leads to better and safer electrolytes.” Spirk and Mondi are already taking this concept into account in the current development of the vanillin-based redox flow battery mentioned above and have already been able to deliver promising results.

Presentation of the ecological redox flow variant at the 3rd NanoSyn Joint Meeting

Stefan Spirk is presenting the concept of the vanillin-based redox flow battery and the SABATLE project on December 14, 2020 at the 3rd NanoSyn Joint Meeting. This event is jointly organized by nanoNET-Austria and the Austrian Microfluidics Initiative (AMI) and will take place virtually this year due to the corona pandemic. Registration is possible until December 11, 2020 via the website of BioNanoNet (in German) where you can also find further information about the event.

The SABATLE project is funded within the SAF€RA framework. SAF€RA is a network of 21 research funding agencies from 10 European countries, which carry out joint calls for proposals and manage projects in the field of industrial research security. In Austria the programme is supported by the FFG.

Participating research partners:

- Institute of Bioproducts and Paper Technology from TU Graz (Lead)

- Institute of Chemical Engineering and Environmental Technology from TU Graz

- BioNanoNet Forschungsgesellschaft mbH

- Institute of Systems Sciences, Innovation and Sustainability Research from the University of Graz

- Mondi AG

- Biobide

This research work is anchored in the Fields of Expertise “Sustainable Systems” and “Advanced Materials Science”, two of the five strategic research foci of Graz University of Technology.

Environmental and safety aspects of battery technologies are also being researched at Graz University of Technology by other research groups, such as the Institute of Vehicle Safety (in the K-Project Safe Battery and the new Battery Safety Center Graz) and by the Institute for Chemistry and Technology of Materials (ICTM).

###

Media Contact

Stefan SPIRK

[email protected]

Original Source

https:/