Credit: Shotaro Hiraide Ph.D., Department of Chemical Engineering, Kyoto University

The Paris Agreement of 2015 set a goal of reducing CO2 emissions, a greenhouse gas that causes global warming to levels less than 2°C more than before the Industrial Revolution. In order to achieve this goal, it is necessary to reduce industrial energy consumption, half of which is used in separation processes for purifying, distilling and drying chemicals. It takes a lot of energy and is costly to separate a mixture of molecules. In other words, the development of a highly efficient and energy-saving separation technology is one of the most important challenges facing the world today, of which CO2 separation and capture is a high priority for lowering greenhouse gases.

The adsorption separation method for separating a mixture of molecules makes use of the property that specific molecules are adsorbed in a porous material. This is how water purifier filters and deodorizing charcoal in refrigerators work. When a gas mixture is poured from one end of an adsorption tower filled with a porous material (adsorbent), molecules that strongly interact with the adsorbent are captured into the pores. Some molecules with a weak interaction with the adsorbent are also adsorbed in the pores, but most pass through and flow out of the adsorption tower. The molecules taken into the pores are recovered or desorbed by heating or depressurizing the content of the adsorption tower. In order to selectively adsorb molecules into an adsorbent, there is a need for a stronger interaction, but the energy required for desorption increases accordingly. The key to greatly improving the adsorption separation efficiency is to find adsorbents with certain contradictory properties that can selectively adsorb large amounts of molecules and easily desorb them.

The pressure vacuum swing adsorption (PVSA) and temperature swing adsorption (TSA) processes, which are both gas separation methods using porous materials, can be more energy efficient than distillation, which requires selective boiling and condensation. However, PVSA and TSA aren’t without their limitations. It is difficult to achieve high-throughput separation with these techniques because pressure loss is caused due to necessary system enlargement as well as the crushing of adsorbents at the bottom of the adsorption column. Previous efforts to resolve these issues have caused other problems such as heat generated by adsorption, which results in a decrease of adsorption capacity, so there is a need to find a novel adsorption material that exhibits a large loading capacity, high selectivity and minimal heat of adsorption, which are actually conflicting characteristics with known materials.

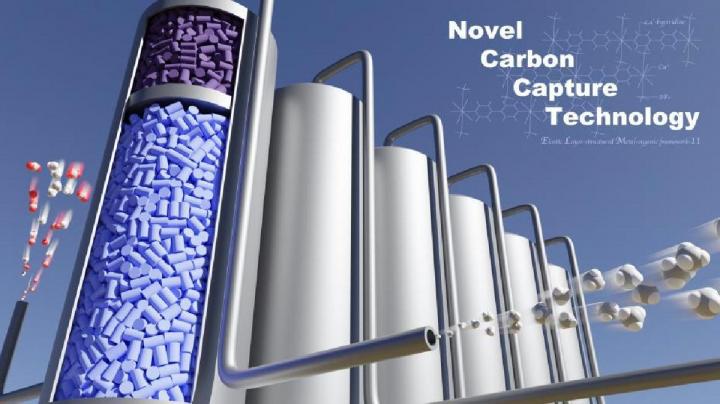

Therefore, the focus of this research was on “gate-type adsorbents”. The greatest feature of this material is that it has a flexible structure. The researchers worked with ELM-11, a flexible metal-organic framework (MOF), which is a porous material with “gate-opening” and “gate-closing” properties exhibited at specific gas pressures. ELM-11’s pores are closed and does not adsorb CO2 when the concentration of CO2 contained in the gas mixture is low, but rapidly expands when the CO2 concentration exceeds a certain threshold value, and opens the pores to capture CO2 molecules. Since the opening and closing behavior of the pores is like a gate, it is called a gate type adsorbent. ELM-11 deforms its structure to encapsulate CO2 molecules, and thus exhibits high CO2 selectivity. Furthermore, ELM-11 contracts its structure and releases all the adsorbed CO2 molecules when the CO2 concentration in the gas mixture falls below a threshold value. In other words, ELM-11 has properties that are highly suitable for CO2 adsorption and separation. It selectively adsorbs CO2 and easily desorbs CO2.

For the real world application of the adsorption separation of CO2 contained in exhaust gas, a large amount of gas must be processed at high speed. The problem is the generation of heat associated with CO2 adsorption. In traditional “hard” adsorbents, the heat of adsorption raises the temperature, resulting in reduced CO2 adsorption and reduced CO2 selectivity. ELM-11, which has a flexible structure, expands when it takes in CO2 molecules. The research group focused on the possibility that the expansion of ELM-11 may generate cold heat and effectively suppress the temperature rise due to CO2 adsorption.

First, they conducted a gas adsorption experiment on ELM-11 and conducted a variety of computational studies to quantify the CO2 separation capacity of ELM-11. They compared performance data with HKUST-1, a conventional adsorbent which is considered to be the most promising for separating CH4and CO2 gas mixtures. The data showed that ELM-11 has a CO2 selectivity 9.7 times that of HKUST-1. The CO2 recovery amount per adsorbent weight is 2.1 times that of HKUST-1, which has no intrinsic thermal management capability. ELM-11 proved to be extremely suitable for high-speed adsorption separation systems.

The researchers designed a high-speed adsorption separation system consisting of two-stage adsorption towers, one packed with HKUST-1. When the CO2 concentration contained in the gas mixture exceeds a certain threshold value, ELM-11 expands rapidly and opens pores, adsorbing CO2 molecules. This means that when the CO2 concentration in the gas falls to the threshold due to CO2 adsorption on ELM-11, the remaining CO2 is not adsorbed at all and flows out with CH4, which means that high-purity CH4 gas is not obtained. Therefore, to prevent this problem the researchers installed a small adsorption column filled with HKUST-1 that has excellent adsorption characteristics for low-concentration CO2 gas, in the latter stage of the adsorption column filled with ELM-11. They conducted a breakthrough measurement for a mixed gas of CH4 and CO2 using a small two-stage adsorption column, and was able to confirm that high-purity CH4 gas was obtained.

The two-stage adsorption tower system enables the reduction of the total tower volume, reduces the amount of adsorbent used, and reduces energy consumed. At first glance, the system is based on a simple idea, but it was possible to reduce the system size significantly in this way by designing the first-stage adsorption tower so that the characteristics of ELM-11 can be fully exhibited. The hybridization system utilizing the characteristics of ELM-11 and HKUST-1 worked extremely effectively.

The researchers needed to clarify three issues to see if ELM-11 possessed the necessary qualities needed for a real-life high-throughput separation process. First, it was necessary that the host framework response for the gate-opening needed to be very fast. Secondly, the separation properties must work for non-isothermal conditions, which has not been previously reported to the knowledge of the researchers. Thirdly, the “slipping-off” phenomenon caused by a decrease in the partial gas pressure below the gate-opening pressure, which makes the flexible MOF unable to adsorb molecules needed to be addressed. ELM-11 showed that the researchers are able to overcome these three issues, the “slipping-off” problem can be managed with the two-stage adsorption tower.

In addition, this system can be applied to the exhaust gas treatment of CO2 emission sources such as thermal power plants. In order to put this high-speed adsorption/separation system that uses a gate-type adsorbent into practical use, the hinderance of gate-opening due to the pelletization of flexible MOFs, and the pressure drop due to the volume expansion of pellets need to be addressed. The team have already started tackling these issues.

The accomplishments of this present research has opened the doors to a new era in gas separation. Corresponding author Hideki Tanaka of Shinshu University states that, “the study took 3 years to publish, which we are very grateful for because the multiple feedback from reviewers was very insightful and the subsequent re-writes made the study more innovative and better, which eventually led to the paper being published in Nature Communications. I’m very happy that the hard work of first author Shotaro Hiraide of Kyoto University was finally rewarded.”

###

Acknowledgements

This work was financially supported by a Grant-in-Aid for JSPS fellows no. 15J05846, a Grant-in-Aid for Research Activity Start-up no. 19K23574, a Grant-in-Aid for Scientific Research (B) no. 17H03097 and no. 20H04466, a Challenging Research (Exploratory) no.18K18975, the ENEOS Hydrogen Trust Fund, JST CREST grant no. JPMJCR1324, Japan and “Five-star Alliance” in “NJRC Mater. & Dev.”. For this work, we used the supercomputer at ACCMS, Kyoto University. The synchrotron radiation experiments were performed at the BL02B2 beamline of SPring-8 with the approval of the Japan Synchrotron Radiation Research Institute (JASRI) (proposal no. 2017B1210, 2018A1082, 2018B1539, 2019B1290).

Media Contact

Hitomi Thompson

[email protected]

Related Journal Article

http://dx.