Credit: Takahiro Muraoka, TUAT

A collaboration mainly led by scientists from Tokyo University of Agriculture and Technology (TUAT) in Japan has developed a new method of molecular design to control both temperature reversibility and stiffness of nanofibers that are gel-forming peptides. The peptide nanofiber hydrogel can be used as biomedical materials. This method will allow the peptide nanofibers more biomedical applicable.

The researchers published their results on July 8th in Chemistry-A European Journal, which was highlighted in the Front Cover and Cover Profile.

In general, some of peptides form nanofiber hydrogels. These peptides are short chains of natural amino acids found in all living organisms. Since these are bio-friendly, these have been widely used in medicine such as tissue recovery materials, regenerative medical materials, extracellular matrices, cell culture materials, and drug delivery containers.

“For some medical applications of nanofiber peptides, we need to develop a technique to control both stiffness (mechanical strength) and temperature response changing between gel (solid) and sol (liquid),” said Takahiro Muraoka, PhD, corresponding author on the paper and associate professor in the Department of Applied Chemistry, Graduate School of Engineering at TUAT. “It is, however, difficult to make better the both features at the same time. For example, when increasing stiffness of a peptide nanofiber by replacement of a simple amino acid alanine to a more hydrophobic amino acid phenylalanine, it is known that temperature response is often lost.”

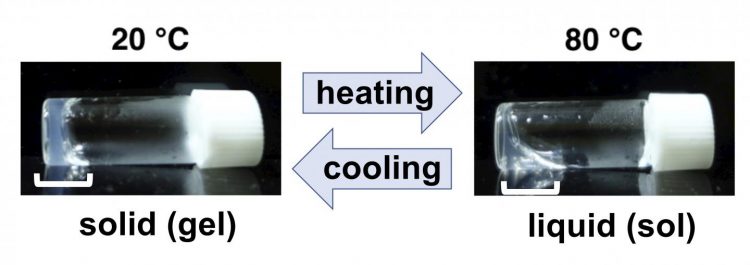

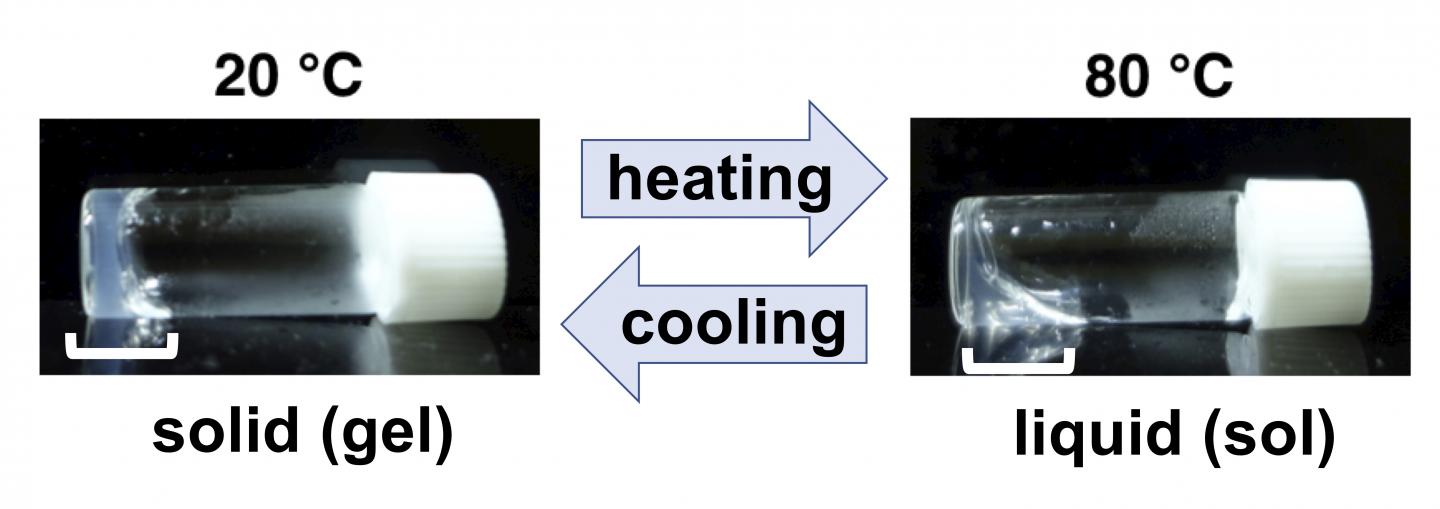

In their experiments, they found that an amino acid replacement that was thought to make a softer gel unexpectedly formed a harder gel. They used 5 sets of different peptides that had 16 amino acids. Interestingly, one particular peptide did not lose temperature response. The peptide (concentration at 1% in solution) formed gel (solid) at 20°C (68°F) and when increasing temperature to 80°C (178°F) the gel became sol (liquid). When reducing temperature from 80°C to 20°C, gel was again formed. “This temperature reversible feature is applicable for drug delivery by local injection,” said Muraoka.

They replaced alanine in the middle of the peptide to glycine, the simplest amino acid. The glycine replacement usually makes the gel softer. They used regular analytical instrument such as CD, IR, and TEM microscopy to understand precisely how the gel was formed. They also used a computational approach, called molecular dynamics simulation. “Based on our results, we are now able to design peptides better by computer simulation,” said Muraoka.

Furthermore, the peptide nanofiber was cell adhesive, which is suitable as a biomaterial for cell culture and tissue regeneration. “This research will open new avenues towards designing peptide nanofibers more biomedical applicable,” Muraoka added.

###

For more information about the Muraoka laboratory, please visit https:/

About Tokyo University of Agriculture and Technology (TUAT):

TUAT is a distinguished university in Japan dedicated to science and technology. TUAT focuses on agriculture and engineering that form the foundation of industry, and promotes education and research fields that incorporate them. Boasting a history of over 140 years since our founding in 1874, TUAT continues to boldly take on new challenges and steadily promote fields. With high ethics, TUAT fulfills social responsibility in the capacity of transmitting science and technology information towards the construction of a sustainable society where both human beings and nature can thrive in a symbiotic relationship. For more information, please visit http://www.

Original publication:

Glycine Substitution Effects on the Supramolecular Morphology and Rigidity of Cell-Adhesive Amphiphilic Peptides.

Atsuya Ishida, Go Watanabe, Mio Oshikawa, Itsuki Ajioka, and Takahiro Muraoka

Chem. Eur. J. 2019, 25, 1-9

10.1002/chem.201902083

This work was supported by JSPS and MEXT Grants-in-Aid for Scientific Research (JP16K21353 and JP17H03038 to G.W., 17H04885 and 17H05147 to T.M.), MEXT Leading Initiative for Excellent Young Researchers (T.M.), JST PRESTO (JPMJPR13KH to T.M., JPMJPR14K1 to I.A.), the research fund of Kanagawa Institute of Industrial Science and Technology (I.A.), TEPCO Memorial Foundation Research Grant (Basic Research to T.M.), and Kitasato University Research Grant for Young Researchers (G.W.).

Contact:

Takahiro Muraoka, PhD.

Associate Professor

Department of Applied Chemistry, Graduate School of Engineering, TUAT, Japan.

E-mail: [email protected]

Media Contact

Yutaka Nibu, Ph.D.

[email protected]

Related Journal Article

http://dx.