AE Professor Phil Ansell set the bar high for phase 1 of a NASA-funded University Leadership Initiative program: to develop new technologies using cryogenic liquid hydrogen as an energy carrier for aircraft. Support from the Illinois-led initiative was used to establish the Center for High-Efficiency Electrical Technologies for Aircraft, to innovate novel power, energy, and configuration systems for a zero-emissions aviation future. Three years later, the nine academic institutions, Boeing, GE, and the Air Force Research Lab cleared the bar and are focused on phase 2: to develop prototypes of their designs.

Credit: The Grainger College of Engineering at the University of Illinois Urbana-Champaign

AE Professor Phil Ansell set the bar high for phase 1 of a NASA-funded University Leadership Initiative program: to develop new technologies using cryogenic liquid hydrogen as an energy carrier for aircraft. Support from the Illinois-led initiative was used to establish the Center for High-Efficiency Electrical Technologies for Aircraft, to innovate novel power, energy, and configuration systems for a zero-emissions aviation future. Three years later, the nine academic institutions, Boeing, GE, and the Air Force Research Lab cleared the bar and are focused on phase 2: to develop prototypes of their designs.

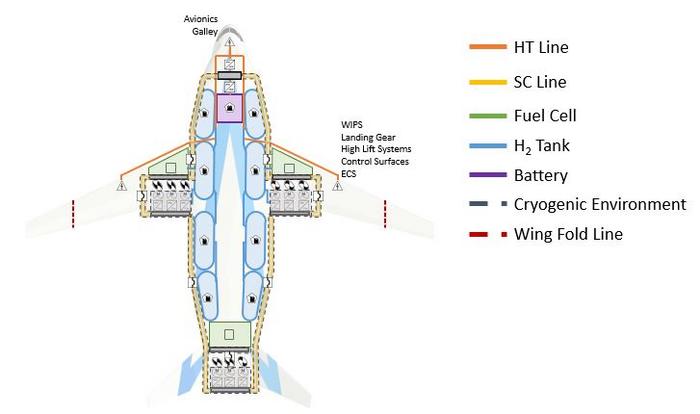

“Because hydrogen takes up a lot of volume, it’s best kept cold in a liquid state. Instead of thinking of that as a barrier, we saw it as an opportunity to leverage those unique characteristics,” said Phillip Ansell, an aerospace engineering professor and director of CHEETA. “We saw a great deal of promise in using the 20 Kelvin cryogenic temperature of liquid hydrogen to enable the use of superconducting technology. Certain classes of materials demonstrate a drop to zero resistance at these temperatures, which removes the primary source of electrical losses that are found in conventional power systems. In this way, we leveraged the liquid hydrogen both as a fuel and as a convenient way to maintain these ultra-low temperatures.”

The first phase of the program consisted of a $6 million award, resulting in the development of several groundbreaking technologies and design concepts over the three-year period.

Ansell said “In phase 1, we developed a vision for how fuel cell technology could be utilized and managed to meet the aggressive power requirements for commercial aircraft, while producing zero carbon dioxide and nitrogen oxide emissions from the vehicle. The team also developed an architecture for a superconducting power transmission system capable of efficiently operating at much lower voltages than most room-temperature systems would require, solving several challenges faced with conventional designs.”

The team also developed a new class of cryogenic electric machines, which were co-designed with electrically powered ducted fan systems. The principles involved in these cryogenic electric machines have similarities to what has already been used on magnetic levitation trains, particle accelerators, and MRIs. To date, no commercial cryogenic electric machines exist for aircraft applications.

Phase 1 included a detailed benchmarking of power electronics components down to temperatures of 4 Kelvin and use of these data to create a new set of cryogenic inverters capable of converting the supplied electrical power from DC to AC, a form the motors can use.

Additional innovations were made in the design of a new class of liquid hydrogen storage systems.

“In many ways, the hydrogen tanks and fuel management system are the heart of the airplane. The tank technology developed in CHEETA is remarkable. Not only are these systems super lightweight, but they were designed with the operating requirements of the aircraft in mind. They are robust enough to withstand the heavy-duty cycling of commercial aircraft while meeting the stringent safety requirements of certification,” Ansell said.

A key component of the CHEETA research was to determine how these advanced components could be configured into an aircraft system.

“We were able to reduce the electrical system losses to below 2 percent, so the whole system is over 98 percent efficient from the output of the fuel cell to turning the rotor of the electric machine,” Ansell said. “This is in line with the ambitious goal we made on day one of the program, and I am incredibly proud of our team for the tremendous work that went into meeting this vision.”

“Finding a way to house the large volume of hydrogen for the concept was tough. However, when I see a large volume requirement, I perceive this as a new opportunity to think differently about aircraft design. We were able to maintain the proven, efficient design of conventional fuselages. However, by blending the tank region into the fuselage to create a section that produces useful lift for the aircraft, we produced a design that is more efficient than current aircraft,”

The system had numerous required safety considerations. “We had to place the tanks high on the aircraft to avoid the risk of tank punctures or fires during emergency landing scenarios,” Ansell said. “Due to its minuscule size, hydrogen is a very slippery molecule, which makes it prone to leaks. Even existing jet fuel handling systems of today’s aircraft commonly experience leaks. Though, hydrogen is incredibly buoyant and can be rapidly vented upwards away from the aircraft. Under these scenarios with hydrogen, we wanted to place the tanks in a way that ensured there was no chance that vapors would enter passenger compartments.”

There were other key developments at the aircraft system level. For example, in moving to a fully electric propulsion system the team seized opportunities to integrate the propulsion system into the aircraft aerodynamic design.

“We used boundary-layer ingestion to reduce propulsive power required and integrate the propulsion system into the design of the high-lift system, all while developing new design tools that permitted the optimization of these configurations. From a design perspective, one of the most significant challenges of operating a fuel cell system is dealing with the tremendous heat loads that are produced. We optimally configured an integration strategy for heat exchangers to recover some of the waste heat in a way that minimized the net drag produced by these devices.”

Ansell recognized that self-imposed constraints made the mission more challenging.

“I wanted this to be a zero emissions airplane that doesn’t backpedal on capabilities while meeting the same performance characteristics of a Boeing 737-800 aircraft. This includes things like cruise speed, payload carrying capability of passengers, range, and airport compatibility,” Ansell said. “I was very tempted to cheat on some of these design requirements, but ultimately, we saw the value of not compromising, because that’s the reality.

“There could be different models for aircraft operation in the future, but there’s not a precedent for extensive fuel burn used by short-range or limited-payload aircraft today, which is why we said, let’s go to the hard problem,” he said. “If we look at the actual greenhouse gas emissions and the environmental impact of aviation, we can’t just assume that aviation as an ecosystem is going to adjust to aircraft with reduced performance capabilities. We need to make the aircraft meet what the customer expects. That’s why we were so dogged in maintaining high-level requirements because it’s the harder problem.”

As with the electrical system requirements, the final CHEETA concept produced from phase 1 successfully indicated an ability to meet the flight performance of the 737-800 aircraft, while producing zero carbon dioxide and nitrogen oxide emissions by the aircraft itself.

Phase 2 will take the conceptual designs the group developed and create prototypes of key components. This begins with the development of a 300-kilowatt cryogenic electrical machine, which would represent a one-eighth-scale version of what was designed for full-size aircraft. This machine will be coupled to a superconducting power transmission demonstrator unit, sized to be capable of peak power in excess of this 300-kilowatt benchmark. The team will also develop a 300-liter prototype of the liquid hydrogen tank technology, as well as a 5.5 percent scale uncrewed aircraft to demonstrate the merits of the lifting fuselage approach to house the voluminous hydrogen fuel.

“The point of phase 1 wasn’t to build an airplane,” Ansell said. “We’ve had the ability to take the creative helm and do what universities do well, come up with ideas. Some ideas might be unconventional but a lot of them are getting traction. They are being ported into the research portfolios of other organizations, both domestic and international. And NASA wants us to take these technologies and advance them, which is why they’re funding us for the next couple of years.

“Everything in phase 1 was essentially a design study backed up by analysis. Now we get to put physical prototypes together. They’ll be smaller and lower power than a full implementation but there’s a lot of learning that happens in terms of what is needed to scale up for primetime and showing that the paper designs and analysis are correct.”

Ansell said probably the biggest challenge of this next phase will be the time constraint to build prototypes quickly.

“Two years is not a lot of time to meet ambitious goals and build innovative hardware,” he said. “We’ll need specialized equipment. We’ll need to get students up to speed with how to assemble and build components. But we have excellent people with precedent for meeting aggressive timetables on previous programs.

“We have a lot of lofty challenges in aviation, notably for sustainability, and we have very few solutions,” Ansell said. “I think NASA has recognized the long-term creative potential of this work. It is likely that zero-emission aircraft in the future will look quite a bit different than our CHEETA phase 1 outcome, but these technologies and integration strategies are vital for the environmental goals set by the aviation industry. We’ve had good reception to the initial ideas and efforts to transfer lessons learned into the industry.”