Significant advances in the understanding of P-Type GaN semiconductor formation mechanisms and techniques enabling mass production of GaN devices

Credit: NIMS

In Gallium Nitride (GaN) implanted with a small amount of magnesium (Mg), NIMS succeeded for the first time in visualizing the distribution and optical behavior of the implanted Mg at the nanoscale which may help in improving electrical performance of GaN based devices. Some of the mechanisms by which introduced Mg ions convert GaN into a p-type semiconductor are also revealed. These findings may significantly expedite the identification of optimum conditions for Mg implantation vital to the mass production of GaN power devices.

The development of GaN based power devices–a promising energy-saving technology–requires fabrication of both n- and p-type GaN semiconductors. p-type GaN semiconductors can be mass produced by introducing Mg ions into GaN wafers and subjecting the wafers to thermal treatment. However, no method existed for assessing the effect of Mg concentrations and thermal treatment temperature on the distribution and optical behavior of Mg implanted into GaN at nanoscale dimensions. In addition, the mechanisms by which p-type GaN forms remained unclear so far. These issues had been hindering the development of technologies enabling mass production of GaN devices.

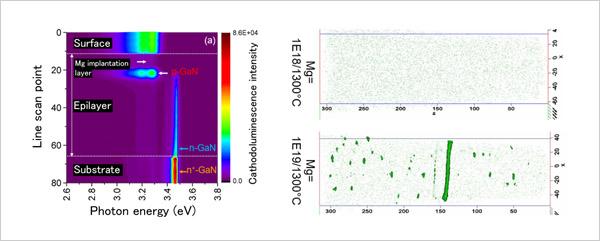

For this research, we prepared slanted cross-sections of Mg ion-implanted GaN wafers by polishing the wafers at an angle and analyzed the distribution of luminescence intensity on the cross-sections using a cathodoluminescence technique. As a result, we found that Mg atoms implanted several tens of nanometers beneath the wafer surface had been activated while those immediately below the surface had not been activated (figure at left). In addition, we found using atom probe tomography that Mg atoms, when implanted in high concentrations, develop into either disc- or rod-shaped deposits depending on temperature (figure at right). The integration of different analytical results generated by these latest microscopy techniques indicated that Mg atoms implanted in the vicinity of the wafer surface may develop into deposits under certain temperature conditions, and thus prevents them from activating.

The results of this research have provided vital guidance for the development of ion-doped p-type GaN layers. Furthermore, the techniques developed during this project for the analysis of impurity distributions are applicable not only in homogeneous wafers but also in GaN device materials with varying structures. The use of these techniques may therefore speed the development of high-performance GaN devices.

###

This project was carried out jointly by a research team led by Tadakatsu Ohkubo (Leader of the CL / EBIC / Atom Probe Group, Center for GaN Characterization and Analysis, Research Network and Facility Services Division [RNFS], NIMS) and Jun Chen (Senior Researcher, CL / EBIC / Atom Probe Group, Center for GaN Characterization and Analysis, RNFS, NIMS) and, a research team led by Masaharu Edo (Senior Manager of the Advanced Materials Reserch Dept., Materials Fundamental Technology Research Center, Advanced Technology Laboratory, Corporate R&D Headquarters, Fuji Electric Co. Ltd.).

This project was conducted under the MEXT “Program for research and development of next-generation semiconductor to realize energy- saving society (Center for GaN Characterization and Analysis).”

Part of this research was published online in Applied Physics Express, a journal of the Japan Society of Applied Physics, on April 11, 2019.

Contacts

(Regarding this research)

Tadakatsu Ohkubo

CL/EBIC/Atom Probe Group

Center for GaN Characterization and Analysis

Research Network and Facility Services Division

National Institute for Materials Science

Tel: +81-29-859-2716

E-Mail: [email protected]

(For general inquiries)

Public Relations Office

National Institute for Materials Sciences

Tel: +81-29-859-2026

Fax: +81-29-859-2017

E-Mail: [email protected]

Media Contact

Yasufumi Nakamichi

[email protected]

Original Source

https:/

Related Journal Article

http://dx.