Credit: Daisuke Matsunaka, Department of Mechanical Systems Engineering, Shinshu University

Magnesium is a promising material for use in structural materials because they are lightweight, have high-specific strength, and high-specific stiffness. However, its limited formability at room temperature keeps its potential use limited.

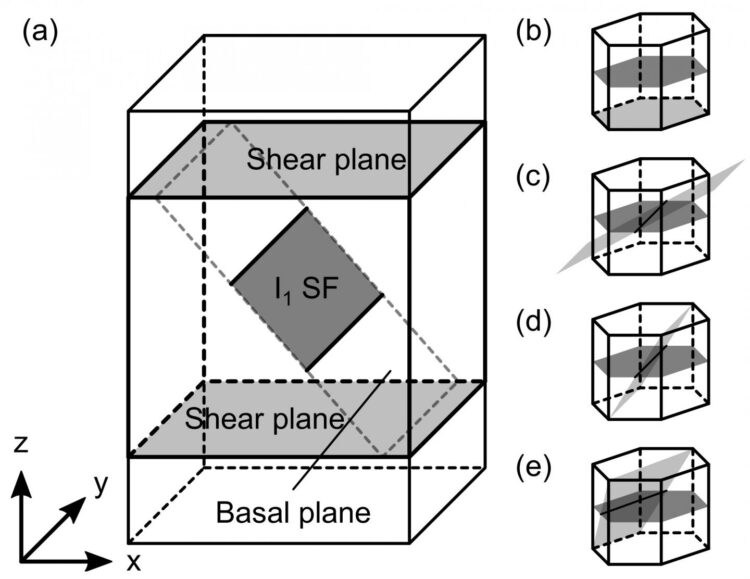

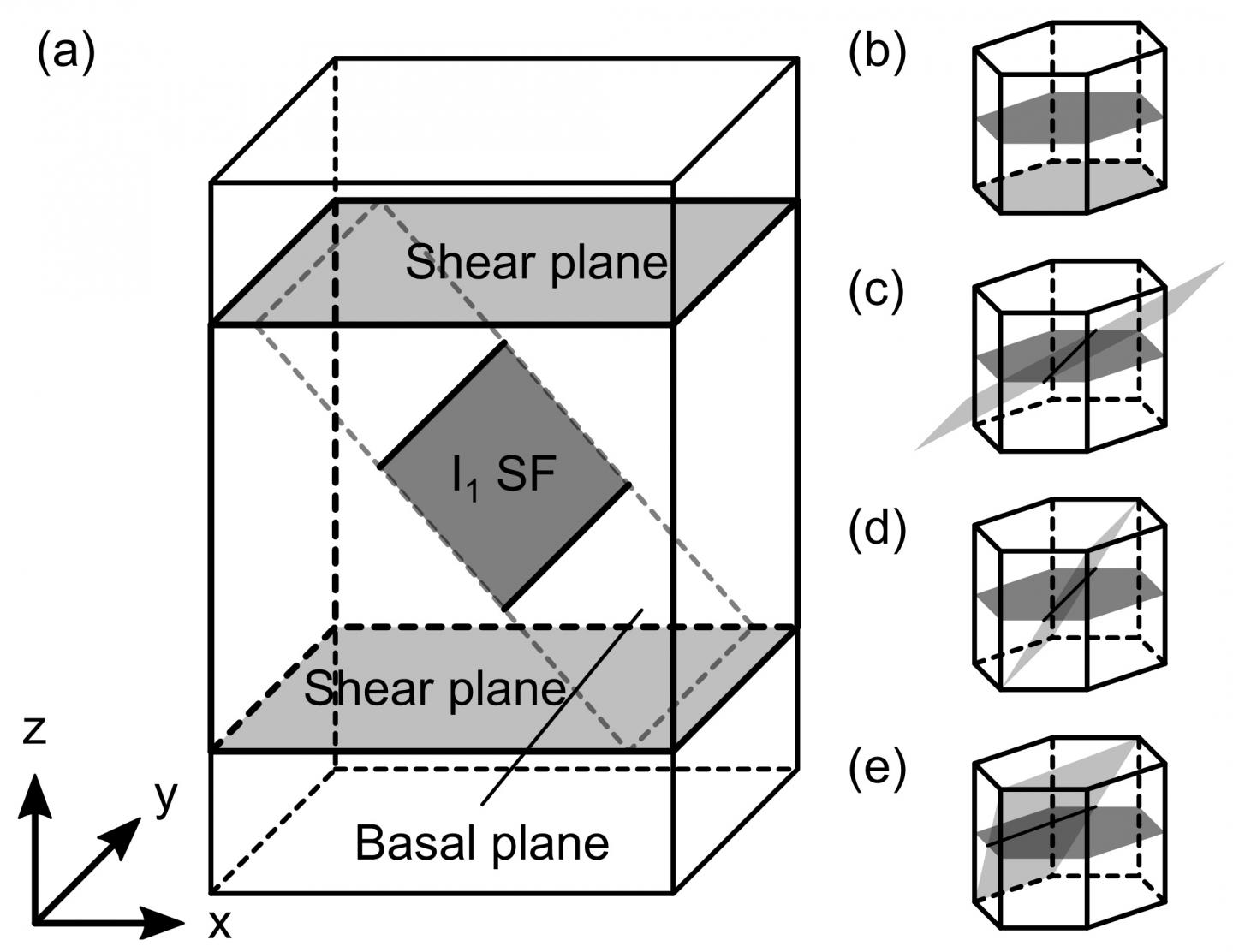

Activation of non-basal slip systems has been observed in several magnesium alloys which showed improvement of ductility. To elucidate the mechanism of the activation of non-basal slip systems, So Yoshikawa and Daisuke Matsunaka of Shinshu University conducted molecular dynamics simulations of defect nucleation in the vicinity of the I1-type stacking fault.

Stacking fault is one kind of defect in crystals. Previous first-principles calculations found that the alloying elements capable of improving ductility reduce the stacking fault energy. Yoshikawa and Matsunaka applied shear stress to atomic models of about 60,000 atoms including an I1-type stacking fault and observed its deformation behavior. Analyzing atomic configurations at each snapshot in the simulations, they discussed defect nucleation from the I1-type stacking fault. Then, they found that

This study successfully obtained the atomistic picture of

Plastic deformation in hexagonal close-packed (HCP) metals such as magnesium is more complex than body centered cubic and face centered cubic metals. Detailed understanding of deformation mechanisms in magnesium, brought from this study and others in the field, would contribute to not only efficient designing high-performance magnesium alloys but also the development of materials science of HCP metals.

###

For more information on the study please read: Defect nucleation from a pre-existing intrinsic I1 stacking fault in magnesium by molecular dynamics simulations.

So Yoshikawa: Conceptualization, Methodology, Software, Formal analysis, Investigation, Writing- original draft, review & editing, Visualization

Daisuke Matsunaka: Conceptualization, Resources, Writing- review & editing, Project administration, Funding acquisition.

Media Contact

Hitomi Thompson

[email protected]

Related Journal Article

http://dx.