“Smart Gear” makes industrial robots more powerful and intelligent

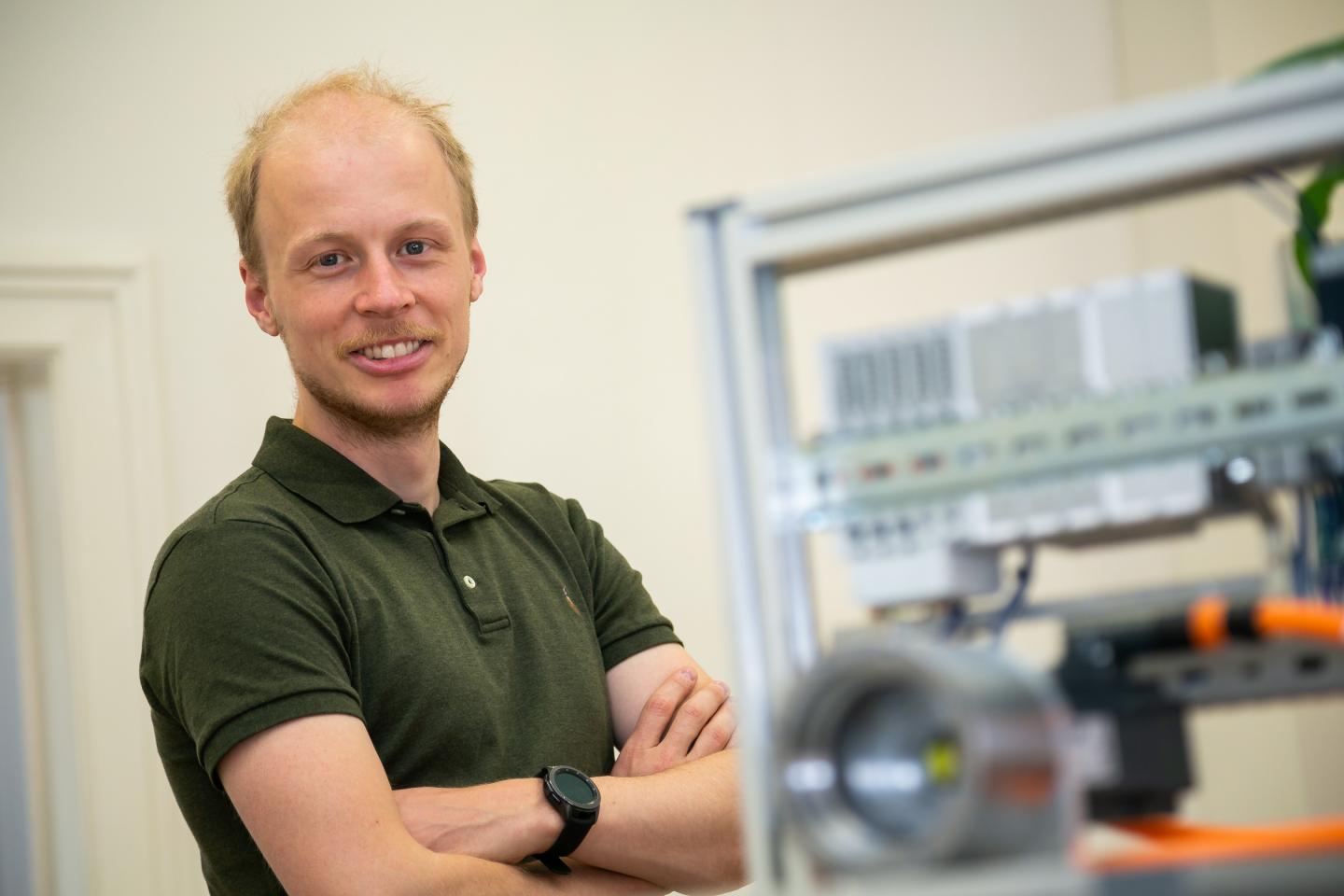

Credit: © Frankl – TU Graz

Additional portrait for download can be found at the end of the message

As part of his master’s thesis at TU Graz, Philipp Eisele developed a concept for a collaborative robot in 2019, i.e. an industrial robot that works together with humans. As a doctoral student at TU Graz’s Institute of Production Engineering, he developed the concept further – and is now the inventor of “Smart Gear”. This is an innovative and meanwhile patented drive system which is currently being implemented as a prototype and could be a watershed in drive technology.

Lightweight with smart interior

The innovative gear principle allows transmission ratios twice as high as previous coaxial gears, as Eisele uses pistons for power transmission instead of revolving gear wheels. “Compared to conventional gear units, the patented system allows the transmission ratio to be doubled while increasing the transmitted torque.” As a result, the size and thus the weight can be halved in comparison to existing gear units without losing effect. The Smart Gear prototype consists of steel and aluminium. The structure is modular, which means that the individual components can be inexpensively produced in mass production and cover a wide range of products through various combinations. “In practice, this means drives will become smaller, lighter and cheaper,” says Eisele, summarising the advantages. The use of Smart Gear is possible with industrial robots, lifting devices and positioning equipment.

The main strength of Smart Gear lies in the available space in the housing, which was created by the elimination of the revolving gears, as Eisele explains: “We can use the empty space for intelligent sensor technology to enable completely new services.” For example, the gear can be connected to cloud services or local company networks, allowing companies to monitor performance data and transmission status in addition to the mechanical system, thus enabling them to manage their production processes efficiently.

Worthwhile payment models

In addition, the networking of the gear opens up new business models that can be used to keep acquisition costs low. Eisele names three types as examples: “As in pay-by-use models, only those hours during which the gear is used are charged for. In fact, the company only pays for the actual duration of use. The system also allows for predictable maintenance. This maximizes uptime and reduces costs for the company. In addition, the maximum power can be limited by software and can be unlocked as needed, allowing a power upgrade without having to replace the gearbox.” With this business model, Smart Gear won the twelfth edition of the Start-Up Garage in 2019 – a cooperation project between TU Graz and the University of Graz that trains students to become the founders of tomorrow – and thus also attracted investment.

System to be further developed with business partners

Pre-series production is scheduled to start this year; initial talks are already underway with robot manufacturers and companies from the manufacturing industry who want to integrate Smart Gear into their products. Eisele is already thinking one step ahead. He would like to make production even more cost-effective and efficient by using innovative manufacturing processes and new materials.

This research is anchored in the Field of Expertise “Mobility & Production” at TU Graz, one of five strategic research core areas of the University.

Media Contact

Philipp EISELE

[email protected]

Original Source

https:/