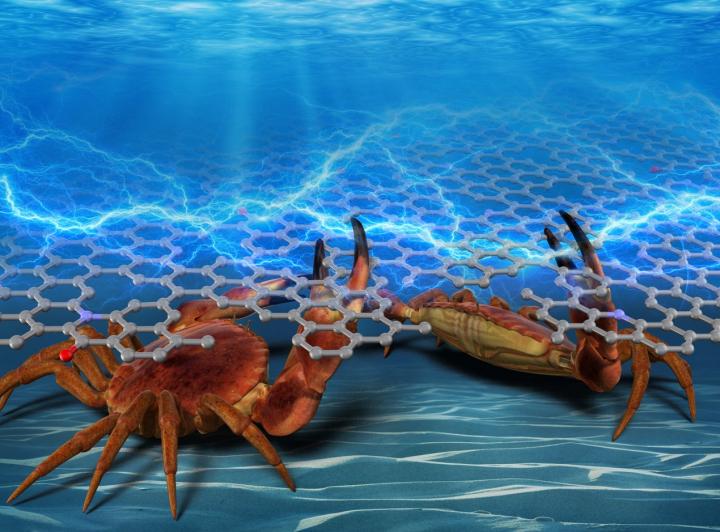

Researchers from Osaka University report a sustainable nanocarbon material made from crab shells that are suitable for use in photosensing and energy storage devices

Credit: Osaka University

Osaka, Japan – As the worldwide demand for electronic devices continues to grow, so too does the strain on the finite resources used in their production, such as metals and fossil fuels. In an effort to provide renewable alternatives, researchers from Osaka University have developed a nanocarbon material for electronics applications made from chitin derived from crab shells. Their findings are published in Journal of Materials Chemistry C.

Nanocarbon materials show significant promise for use in electronic devices. In particular, those with porous three-dimensional (3D) structures provide efficient networks for the transport of charge as well as electrolytes and reactants. The flow through these networks can be further improved by the addition of imperfections–known as defects–in the form of different atoms, such as nitrogen.

Efforts to use both synthetic polymers and biomass to prepare 3D porous nanocarbon with defects, have led to effective sensing, energy storage, and electrocatalysis materials. However, many of these are made from non-renewable resources or require multiple steps to prepare the network and introduce the defects.

The researchers have therefore developed 3D porous defective nanocarbon materials through the simple pyrolysis–or thermal decomposition–of chitin nanofiber paper. Chitin is a biopolymer that is the major component of crustacean shells. Because the structure of chitin contains nitrogen atoms, it acts as its own source of defects and no doping steps are required.

“We were able to control various properties of the final nanocarbon materials by pyrolyzing the chitin nanofiber paper at different temperatures,” says study first author Luting Zhu. “The pore structure, specific surface area, and electrical resistivity all varied with the pyrolysis temperature, providing us with a useful means of tuning the material for specific applications.”

The pyrolyzed chitin nanofiber papers were successfully used as photosensors–exhibiting lower resistance when exposed to light. They were also shown to be effective supercapacitor electrodes (electrical components that can store electric charge in an electric field), with higher specific capacitance than many other nanocarbon materials reported to date, indicating their potential for use in energy storage.

“In order to translate laboratory findings into products that make a significant impact in the real world it is important to streamline processes, which is why we are excited about our simple pyrolysis treatment,” study corresponding author Hirotaka Koga explains. “Furthermore, our successful use of a renewable resource that is generally considered a waste product demonstrates the viability of sustainable electronics.”

###

The article, “Pyrolyzed chitin nanofiber paper as a three-dimensional porous and defective nanocarbon for photosensing and energy storage,” was published in Journal of Materials Chemistry C at DOI: https:/

About Osaka University

Osaka University was founded in 1931 as one of the seven imperial universities of Japan and is now one of Japan’s leading comprehensive universities with a broad disciplinary spectrum. This strength is coupled with a singular drive for innovation that extends throughout the scientific process, from fundamental research to the creation of applied technology with positive economic impacts. Its commitment to innovation has been recognized in Japan and around the world, being named Japan’s most innovative university in 2015 (Reuters 2015 Top 100) and one of the most innovative institutions in the world in 2017 (Innovative Universities and the Nature Index Innovation 2017). Now, Osaka University is leveraging its role as a Designated National University Corporation selected by the Ministry of Education, Culture, Sports, Science and Technology to contribute to innovation for human welfare, sustainable development of society, and social transformation.

Website: https:/

Media Contact

Saori Obayashi

[email protected]

Related Journal Article

http://dx.