Unlocking New Frontiers in Additive Manufacturing: A Focus on 921A Steel

In the realm of modern manufacturing, Wire and Arc Additive Manufacturing (WAAM) stands out as a transformative approach for constructing complex steel components. The intrinsic characteristics of this technique make it particularly effective for producing large-scale structures, combining efficiency, versatility, and adaptability to diverse environments. One of the materials receiving significant attention in this domain is 921A steel, a low-alloy and high-strength steel that has become increasingly popular for its remarkable mechanical properties, toughness, corrosion resistance, and weldability. With applications ranging from shipbuilding to ocean engineering, the importance of WAAM technology for fabricating and repairing critical components from 921A steel cannot be overstated.

The process of WAAM is not merely a straightforward application of metal deposition; rather, it encompasses a complex interplay of multi-scale and multi-physics mechanisms. At a macro level, this includes heat and mass transfer phenomena, while at a microscopic level, it involves grain growth kinetics within the melt pool during the additive manufacturing process. The interaction between grain nucleation and growth is a determining factor in establishing the final microstructure, which, in turn, significantly impacts the mechanical properties of the material. Therefore, understanding the unique thermal history experienced during manufacturing is crucial for achieving uniform microstructures and optimizing mechanical performance in WAAM components.

Recent advancements in simulation technologies have opened new avenues for researchers investigating these intricate processes. Leading this charge is a team of material scientists from Shandong University in China, who, under the guidance of Professor Lei Shi, have developed a groundbreaking multi-scale model that incorporates computational fluid dynamics (CFD) with cellular automata (CA) methods. This innovative approach facilitates a comprehensive understanding of the thermal processes and microstructural evolution occurring in the molten pool during the WAAM of 921A steel. Utilizing the open-source ExaCA code for their simulations, the researchers have effectively predicted the temperature and flow fields as well as microstructural changes within the sedimentary layers of this steel.

Their published findings in the journal Materials and Solidification highlight a systematic study of the single-layer and single-pass deposition experiments conducted with 921A steel. Observations noted during the experiments revealed that the macroscopic metallographic structure of the deposited layer is characterized by columnar grains that align with the direction of heat flow, thereby organized into granular bainite and ferrite structures. This alignment not only provides insights into the solidification process but also indicates how thermal dynamics influence grain orientation within the material.

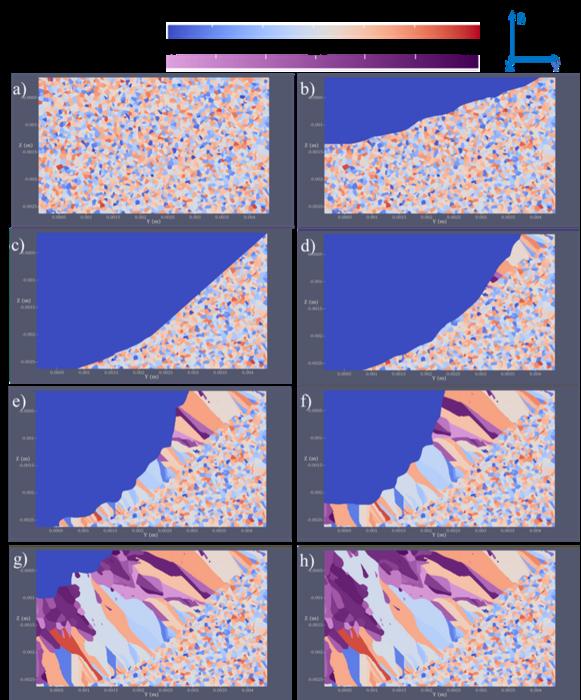

By employing FLOW-3D software, the team was able to simulate both the macroscopic temperature and flow fields inherent in the WAAM process. The results demonstrated fascinating insights into the behavior of molten metal, particularly noting how the mobility of molten pool metal diminishes at higher melting speeds. The correlation between simulation results and experimental forming dimensions was notably consistent, reinforcing the validity of their computational predictions.

Critical to their findings is the understanding that accurate macro-scale thermal modeling serves as an essential input for subsequent microstructure simulation. By feeding solidification data from the thermal model into future cellular automata simulations, researchers can better predict the evolution of microstructures under varied manufacturing conditions. Utilizing the ExaCA code, they simulated the solidification processes in the melt pool’s cross-section, revealing how columnar crystals grew towards the melt pool’s center, leading to the formation of equiaxed grains that obstructed the growth of original columnar structures.

Despite these advancements, researchers acknowledge the necessity for ongoing investigations into the microstructural evolution during the WAAM process for 921A steel. Professor Shi emphasized that more detailed studies are required to quantitatively analyze grain size, grain orientation, and achieve larger-scale microstructure simulations. Their collective efforts underscore the importance of exploring new research trajectories that will enhance the understanding of additive manufacturing’s complexities.

In addition to Shi, the research group comprised notable contributors such as Xiaohui Lyu, Ji Chen, Chuansong Wu, and Ashish Kumar from the School of Materials Science and Engineering at Shandong University, along with experts from the Metals and Chemistry Research Institute in Beijing and Shandong Aotai Electric Co., Ltd. in Jinan. The multifaceted nature of this study highlights the collaborative efforts necessary for pushing the boundaries of knowledge in this burgeoning field.

The research initiative was supported through several esteemed grants, showcasing the importance of collaborative funding efforts in advancing scientific inquiry. These included the National Key Research and Development Program of China, the National Natural Science Foundation of China, the Shandong Provincial Science Foundation for Outstanding Young Scholars, and other critical regional development programs. Such supportive frameworks not only underscore the significance of this research but also emphasize the global interest in optimizing materials science for additive manufacturing applications.

In conclusion, the exploration of WAAM technology combined with the specific properties of 921A steel signifies a pivotal advancement in additive manufacturing. The findings from Lei Shi and his team contribute vital knowledge that facilitiates the development of enhanced microstructures, leading to mechanically superior components for critical applications. As the fields of materials science and engineering evolve, ongoing research promises to unravel the complexities of additive manufacturing, fostering innovations that can ultimately revolutionize how large-scale components are fabricated in industries across the globe.

Subject of Research: The impact of multi-scale simulation on the thermal processes and microstructure evolution in WAAM of 921A steel.

Article Title: Multi-scale simulation of thermal processes and microstructure evolution in wire arc additive manufacturing of 921A steel

News Publication Date: 22-Jan-2025

Web References: Materials and Solidification

References: Relevant research papers, government grants, and articles on WAAM and 921A steel.

Image Credits: Courtesy of Tsinghua University Press.

Keywords: Additive manufacturing, Wire and Arc Additive Manufacturing, 921A steel, microstructure evolution, thermal modeling, computational fluid dynamics, cellular automata, welding technologies.