In the quest for cleaner, more efficient energy conversion technologies, symmetric solid oxide fuel cells (SSOFCs) have garnered significant attention as promising candidates. These devices, distinguished by their symmetrical electrode configuration, offer substantial advantages, including reduced fabrication complexity and enhanced durability over traditional asymmetric cells. Recent advancements spotlight the integration of ammonia (NH3) as a sustainable fuel source, leveraging its high energy density and carbon-free nature. This emerging synergy of SSOFC technology and ammonia fuel sets the stage for transformative breakthroughs in energy systems.

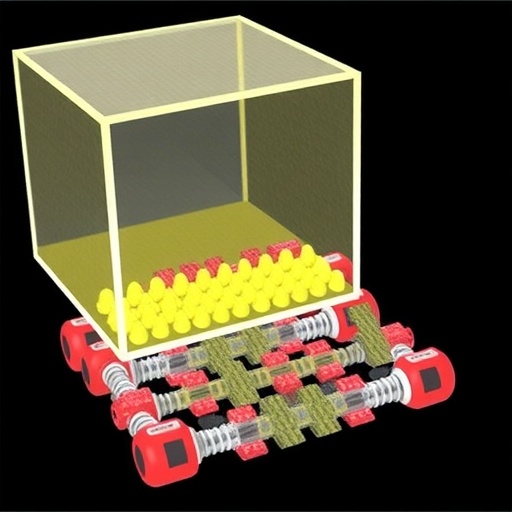

Central to these advancements is the development of novel electrode materials capable of catalyzing fuel oxidation with high efficiency and resilience. Researchers have synthesized a bifunctional perovskite electrode designated as Pr₀.₃₂Sr₀.₄₈Fe₀.₇₅Ni₀.₂Ru₀.₀₅O₃-δ (PSFNRu), achieved by judiciously doping 5 molar percent ruthenium (Ru) into the parent Pr₀.₃₂Sr₀.₄₈Fe₀.₈Ni₀.₂O₃-δ (PSFN) matrix. This precise compositional tuning not only introduces substantial oxygen vacancies but also induces the in situ exsolution of metallic alloy nanoparticles under reducing atmospheres. These dynamically formed nanoparticles serve as prolific catalytic centers, substantially amplifying electrochemical reactions essential to fuel cell performance.

The strategic inclusion of ruthenium addresses intrinsic limitations commonly observed in conventional perovskite electrodes. Oxygen vacancies embedded within the PSFNRu structure enhance ionic conductivity by facilitating oxygen ion migration, a critical factor in elevating electrode reactions. More importantly, the exsolution mechanism yields alloy nanoparticles firmly anchored on the electrode surface, which mitigates particle sintering and agglomeration—a frequent cause of performance degradation in prolonged operation. This structural stability directly translates to superior longevity and sustained catalytic activity during fuel cell operation.

Electrochemical evaluations demonstrate that SSOFCs utilizing the PSFNRu electrode exhibit outstanding power outputs. When fueled with hydrogen (H₂), the cell delivers a peak power density reaching 736 mW cm⁻² at 800°C, a significant enhancement compared to the undoped PSFN-based system. More impressively, the cell maintains a formidable 547 mW cm⁻² peak power density using ammonia as the direct fuel source, underscoring the robust catalytic aptitude of the PSFNRu electrode in handling NH3 decomposition and subsequent electrochemical oxidation.

The direct utilization of ammonia as a fuel within SSOFC frameworks addresses pressing challenges associated with hydrogen storage and transportation. Ammonia’s inherent attributes—high volumetric energy density, easy liquefaction, and carbon-free combustion products—render it an effective hydrogen carrier and a practical fuel alternative for large-scale deployment. However, its complex decomposition and potential poisoning effects necessitate the incorporation of advanced electrode materials capable of efficient NH3 cracking and electrooxidation within the same electrode structure, a criterion met impressively by PSFNRu.

Durability assessments further reinforce the viability of the PSFNRu electrode in operational environments. The cell sustains stable performance for over 172 hours at 700°C when directly fueled with ammonia, with negligible degradation observed throughout this extensive period. This endurance is a testament to the structural integrity and catalytic resilience imparted by the ruthenium doping and nanoparticle exsolution phenomena. Such operational longevity is critical for real-world applications, where continuous, maintenance-free service is a prerequisite.

The implications of these findings extend beyond mere performance metrics. The bifunctional nature of the PSFNRu electrode, combining oxygen ion conductivity and fuel catalytic activity, streamlines cell fabrication by enabling symmetrical cell configurations. This symmetry simplifies manufacturing logistics and reduces material incompatibility issues commonly encountered in heterogeneous electrode assemblies. Consequently, it opens pathways toward cost-effective, scalable production of SSOFC stacks optimized for direct ammonia utilization.

Mechanistically, the PSFNRu electrode operates through a synergistic interaction between its crystalline lattice and surface nanoparticles. Oxygen vacancies within the perovskite facilitate facile oxygen ion diffusion to the triple-phase boundary, while the surface-anchored alloy nanoparticles catalyze the breakdown of NH3 molecules into nitrogen and hydrogen species. The liberated hydrogen then undergoes electrochemical oxidation, producing electricity and benign nitrogen—an environmentally friendly fuel cell reaction that aligns with global decarbonization goals.

From a materials science perspective, the judicious doping with Ru not only tailors the electronic structure of the perovskite but also stabilizes the exsolved alloy nanoparticles against coarsening at high temperatures. This attribute ensures consistent catalytic activity over extended cycles, overcoming conventional electrode degradation modes such as particle sintering and phase segregation. Raman spectroscopy, X-ray diffraction, and electron microscopy analyses corroborate these microstructural and compositional stabilities, providing robust evidence for the electrode’s enhanced functional attributes.

Beyond fundamental insights, the practical ramifications of this research position the PSFNRu-based SSOFC as a competitive technology for stationary and mobile power generation. Its capability to operate efficiently on ammonia paves the way for integrating renewable ammonia synthesis pathways, such as electrochemical nitrogen reduction powered by intermittent renewables, thereby closing the sustainable energy loop. This convergence of advanced electrochemical materials and green fuel infrastructures holds transformative potential for future energy landscapes.

In summation, the development of PSFNRu marks a significant leap in SSOFC electrode technology, effectively bridging the gaps between high performance, durability, and operational simplicity. Its superior power density performance with both hydrogen and ammonia fuels, combined with sustained stability under realistic operating conditions, renders it an exemplary candidate for next-generation direct ammonia SSOFC systems. As global energy demands evolve, such innovations will be pivotal in securing a sustainable, carbon-neutral energy future.

Subject of Research: Development of bifunctional perovskite electrodes for direct ammonia-fueled symmetric solid oxide fuel cells.

Article Title: Ruthenium-Doped Praseodymium-Strontium-Ferrite-Nickelate Perovskite Electrodes Enable High-Performance Direct Ammonia Symmetric Solid Oxide Fuel Cells

News Publication Date: Information not provided.

Web References: Information not provided.

References: Information not provided.

Image Credits: Image courtesy of EurekAlert.

Tags: ammonia as a carbon-free fuelbifunctional electrodes for fuel cellsCobalt-free nanocompositesdirect ammonia solid oxide fuel cellselectrochemical performance enhancementenergy conversion technologieshigh efficiency fuel oxidation catalystsin situ exsolution of nanoparticlesionic conductivity in fuel cellsruthenium-doped perovskite materialssustainable fuel sources for energysymmetric solid oxide fuel cells