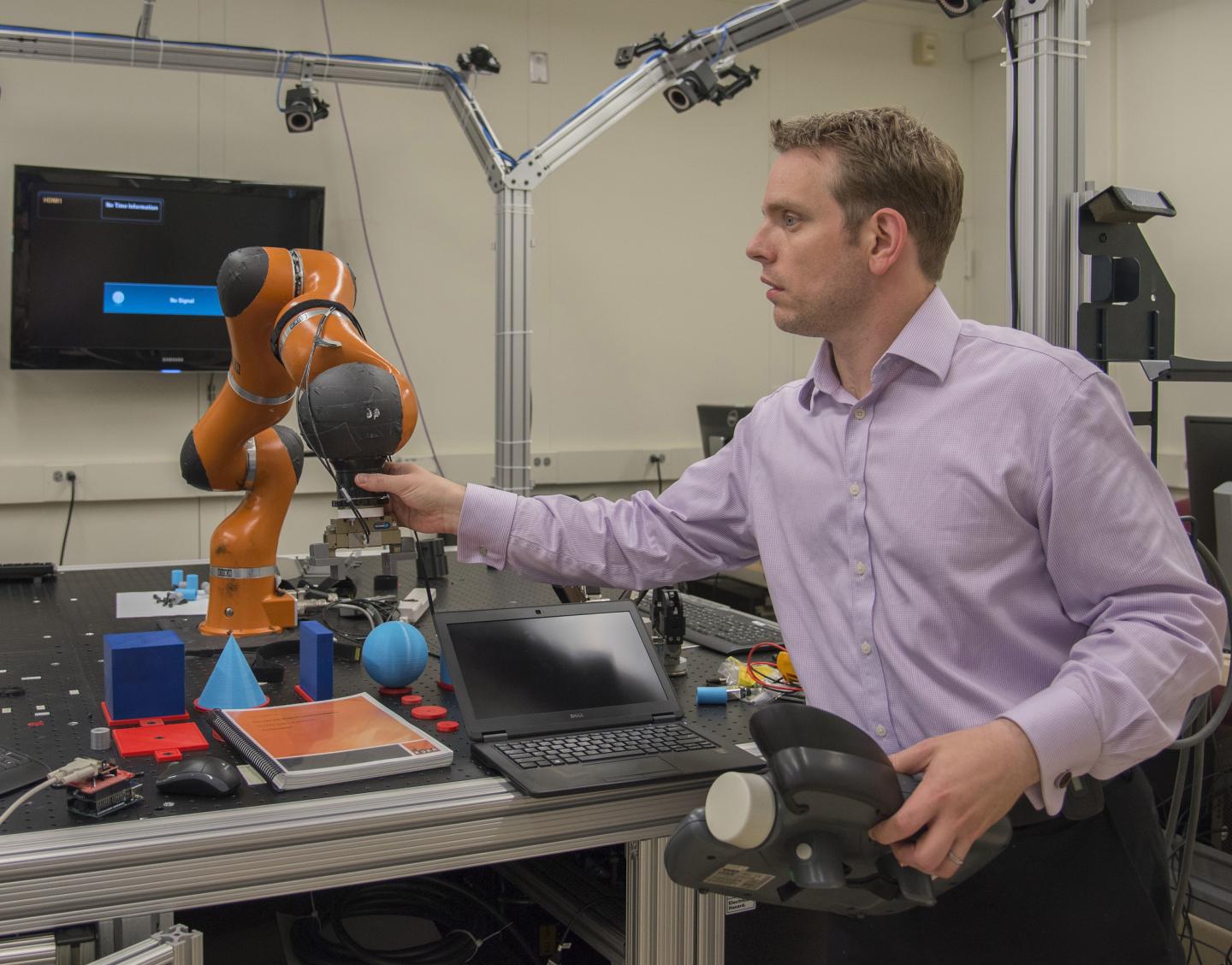

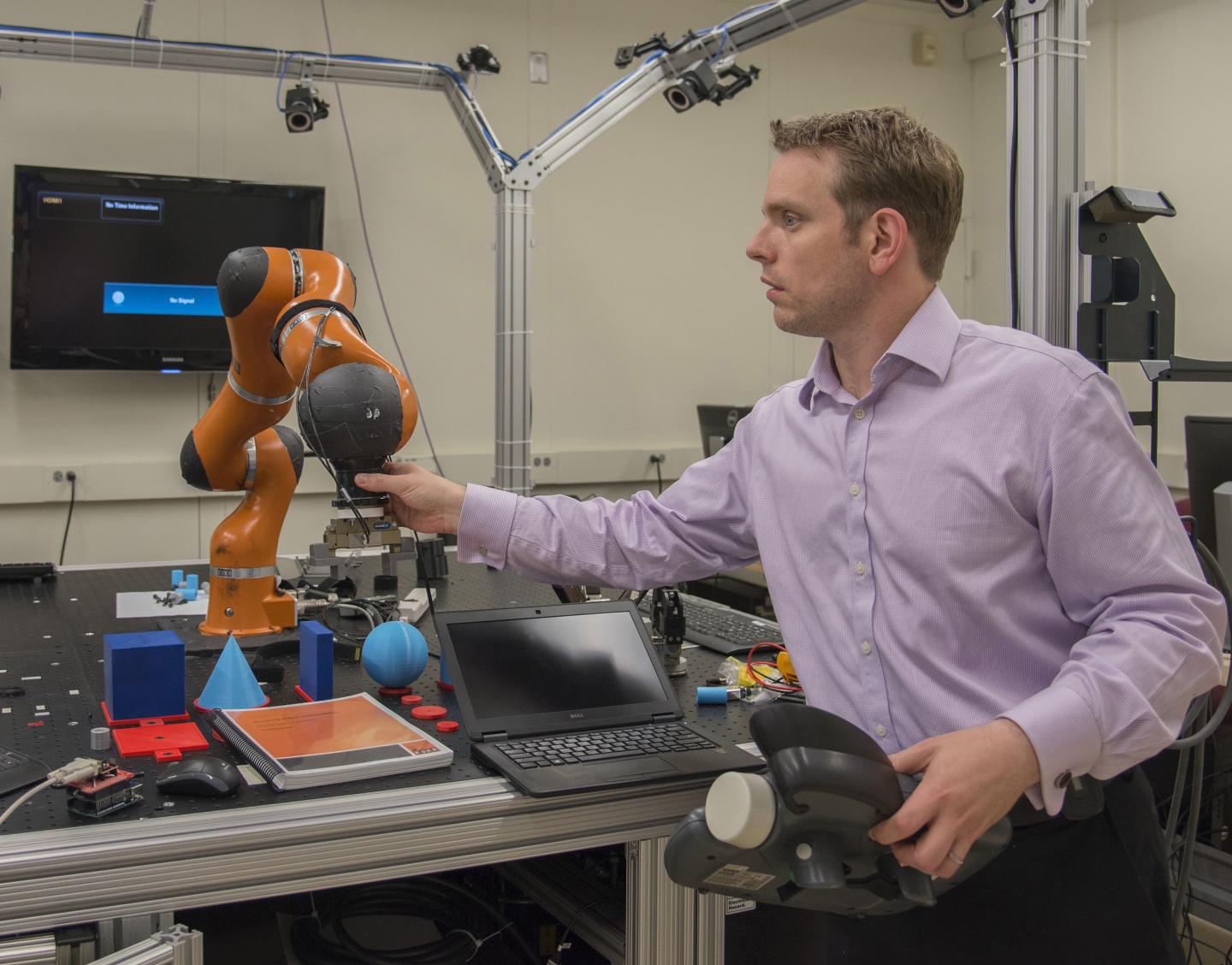

Credit: Fran Webber/NIST

To spur significant innovation and growth in advanced manufacturing, as well as save over $100 billion annually, U.S. industry must rectify currently unmet needs for measurement science and "proof-of-concept" demonstrations of emerging technologies. This is the overall conclusion reached by economic studies funded by the National Institute of Standards and Technology (NIST) of four advanced manufacturing areas used to create everything from automobile composites to zero-noise headsets.

"Gaps in the technology infrastructure–including the lack of reliable measurement and test methods, scientifically based standards, and other formal knowledge and tools–limit advanced manufacturing's further development and adoption," said NIST economist Gary Anderson, coordinator of the economic studies prepared by RTI International (link is external), an independent nonprofit research institute.

Using data collected through extensive interviews and surveys with researchers, developers, manufacturers and other stakeholders, each of the four studies identifies 5 to 10 critical technical barriers to the adoption of its specific manufacturing technology. The studies also estimate the impacts of eliminating those obstacles and define which needs should be met first to do so.

For example, establishing industry-wide standards and measurements for the inks and substrates used in roll-to-roll (R2R) manufacturing–the fabrication of electronic devices on a roll of flexible plastic or metal–is projected to reduce production costs by 15 percent. Likewise, the development and adoption of verified reference data, robust measurement technologies and testing protocols, and standardized modeling and finishing methods could yield some $4 billion in annual benefits and savings for additive manufacturing, a process also known as 3D printing.

The two largest predicted cost savings were the $57.4 billion and $40.1 billion for the smart manufacturing (where all manufacturing data from design to finished product is electronically exchanged and processed) and advanced robotics and automation sectors, respectively. Among the needs that must be met to realize both of these benefits, the researchers said, is increasing access by small- and medium-sized manufacturers to the same state-of-the-art methods, tools and knowledge as their larger counterparts.

For each of the four advanced manufacturing technologies studied, the estimated annual cost savings and percentage reduction in production costs are:

- Additive manufacturing: $4.1 billion, 18.3 percent

- Advanced robotics and automation: $40.1 billion, 5.3 percent

- Roll-to-roll manufacturing: $400 million, 14.7 percent

- Smart manufacturing: $57.4 billion, 3.2 percent

The researchers stated that their studies only looked at benefits directly attributable to closing the identified technical gaps in each sector; therefore, the impact estimates are conservative. "If we consider the larger-scale outcomes brought about by meeting these needs–such as new and improved products, increased production quality, long-term industry growth and job creation–the impacts would be significantly higher," Anderson said.

The studies also support a number of key strategies for overcoming technical barriers and fortifying advanced manufacturing, including: keeping standards and performance measures nonproprietary, using public research institutions to develop those tools, and working through manufacturing research consortia and technology extension services to ensure that all manufacturers–especially small- and medium-sized enterprises–can access them.

"Our studies emphasize that full economic impact will only be realized if all technical needs are met, and all stakeholders regardless of size, not just large manufacturers, can share in the rewards," Anderson said.

###

A summary of the overall findings from the four economic studies is available at http://nvlpubs.nist.gov/nistpubs/eab/NIST.EAB.1.pdf.

The individual reports also may be accessed:

- Additive manufacturing: http://nvlpubs.nist.gov/nistpubs/gcr/2016/NIST.GCR.16-006.pdf

- Advanced robotics and automation: http://nvlpubs.nist.gov/nistpubs/gcr/2016/NIST.GCR.16-005.pdf

- Roll-to-roll manufacturing: http://nvlpubs.nist.gov/nistpubs/gcr/2016/NIST.GCR.16-008.pdf

- Smart manufacturing: http://nvlpubs.nist.gov/nistpubs/gcr/2016/NIST.GCR.16-007.pdf

Media Contact

Michael E. Newman

[email protected]

301-975-3025

@usnistgov

http://www.nist.gov

############

Story Source: Materials provided by Scienmag