Credit: Zhengmao Lu and Ningxin Chen

Scientists have developed a bilayer passive cooling technology inspired by the way camels stay cool in the hot desert sun. The technology’s bottom hydrogel layer acts like a camel’s sweat glands, lowering the temperature through evaporating water, whereas the top aerogel layer functions like fur, insulating against outside heat while letting water vapor pass through. The research, published November 11 in the journal Joule, demonstrates that the design keeps products cool five times longer than conventional single-layer approaches.

“While previous passive cooling research focused on mimicking the evaporation from sweat glands in mammals, in this work we identified the crucial role of the fur insulation,” says Jeffrey Grossman, head of the Department of Materials Science and Engineering at Massachusetts Institute of Technology and a senior author of the study. “By mimicking the dual fur/gland system in camels, we designed an evaporation-insulation bilayer, which, like for the camel, allows for a significant extension of the passive evaporative cooling time for the same amount of water consumption.”

As the climate warms and technology becomes increasingly necessary to keep buildings cool and preserve food and pharmaceuticals, scientists are in hot pursuit of passive cooling methods that do not require external energy sources. Although approaches based on evaporation from hydrogels present one of the most promising passive cooling solutions, they tend to require significant amounts of water and have limited potential for long-term use.

By thinking about these issues in terms of desert-animal physiology, Grossman and colleagues realized that a key component was missing from existing evaporative cooling technologies.

“Zoologists have reported that a shorn camel has to increase the water expenditure for sweating by 50% in the daytime compared to the one with a natural woolly coat,” says Grossman. “And so, to minimize water loss while preserving the cooling power of evaporation, and therefore extend the cooling capabilities over longer periods of times, we turned our attention to nature.”

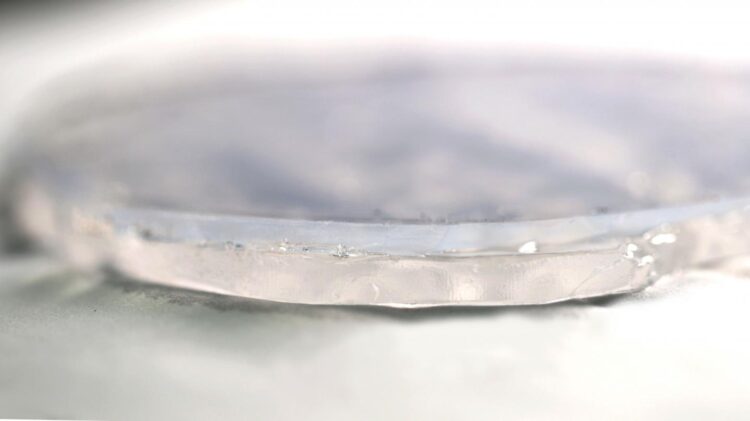

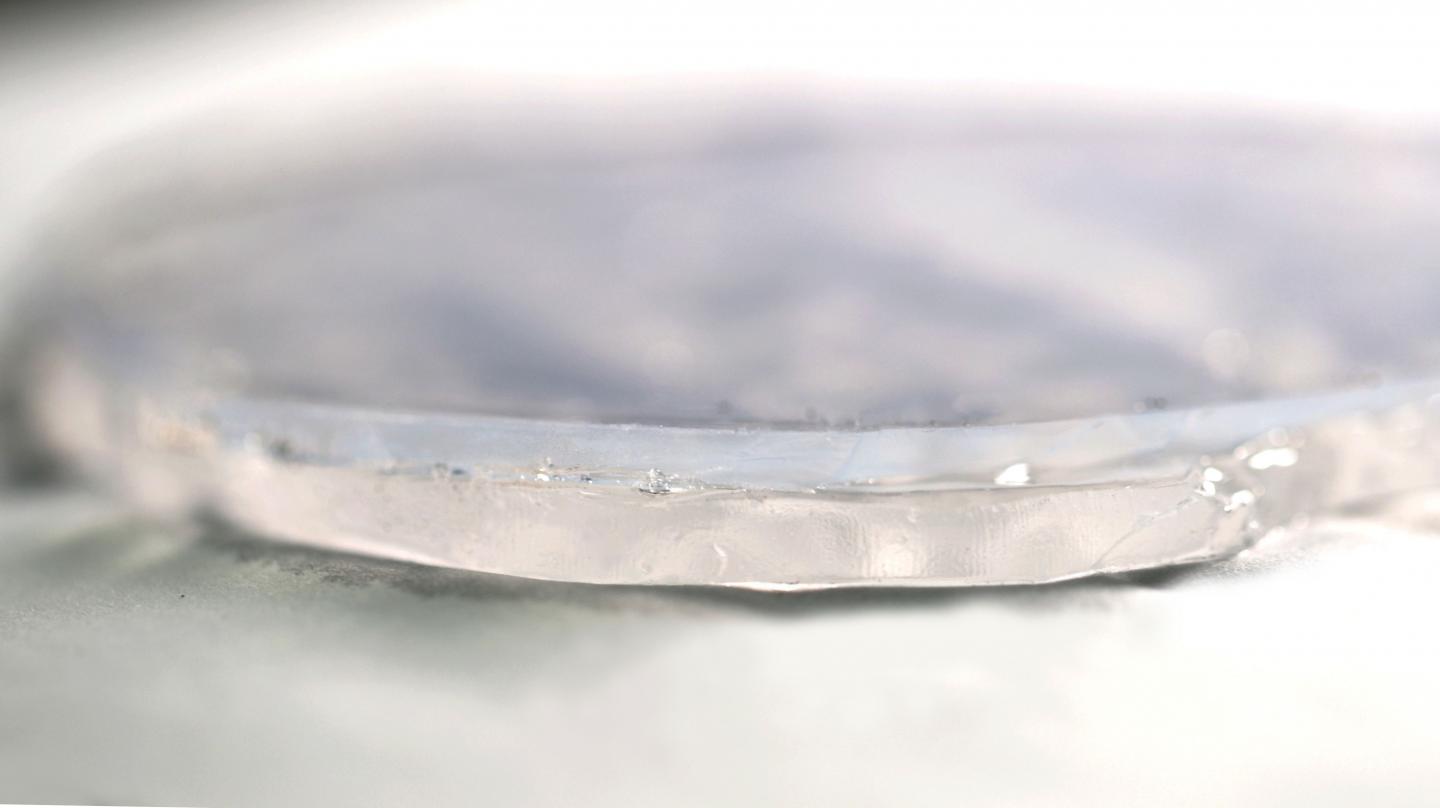

To mimic a camel’s fur layer, the researchers synthesized highly porous, hydrophobic silica aerogels with about half the thermal conductivity of air, then combined them with sweat gland-mimicking hydrogels. The team then tested a sample of the resulting bilayer in an enclosed chamber with controlled ambient temperature and relative humidity, demonstrating that the sample could maintain a temperature 7 degrees Celsius lower than its surroundings. A cooling technology with only the hydrogel layer could maintain a slightly lower temperature, but the bilayer technology lasted far longer. A 5-millimeter layer of hydrogel covered by a 5-millimeter aerogel maintained its temperature for 200 hours before its moisture was depleted and it needed to be recharged with water, whereas a hydrogel layer alone persisted for only 40 hours.

Because of its ability to keep objects cool for an extended period of time without electricity, the bilayer passive cooling technology could enable distributors to ship, transport, and temporarily store products without air conditioning–a service that would be especially useful in regions of the world where electricity remains scarce.

“This technology could also allow for significant miniaturization of conventional evaporation technologies, as it provides move effective cooling for longer times for any given amount of water provided,” says Grossman. “It can also potentially assist thermal management of buildings where the demand for cooling has rapidly increased.”

However, the aerogel layer that gives the technology its edge currently limits its ability to be scaled up for widespread use. “While the material cost of our aerogel is low, the manufacture cost is currently the bottleneck for scalability due to a critical-point drying step,” says Grossman, noting that one of the coauthors, Elise Strobach, has co-founded a start-up company to pursue scalable production of transparent aerogels for building window applications.

###

Joule, Lu et al.: “Passive Sub-Ambient Cooling from a Transparent Evaporation-Insulation Bilayer” https://www.cell.com/joule/fulltext/S2542-4351(20)30494-3

Joule (@Joule_CP), published monthly by Cell Press, is a new home for outstanding and insightful research, analysis, and ideas addressing the need for more sustainable energy. A sister journal to Cell, Joule spans all scales of energy research, from fundamental laboratory research into energy conversion and storage to impactful analysis at the global level. Visit http://www.

Media Contact

Carly Britton

[email protected]

Related Journal Article

http://dx.