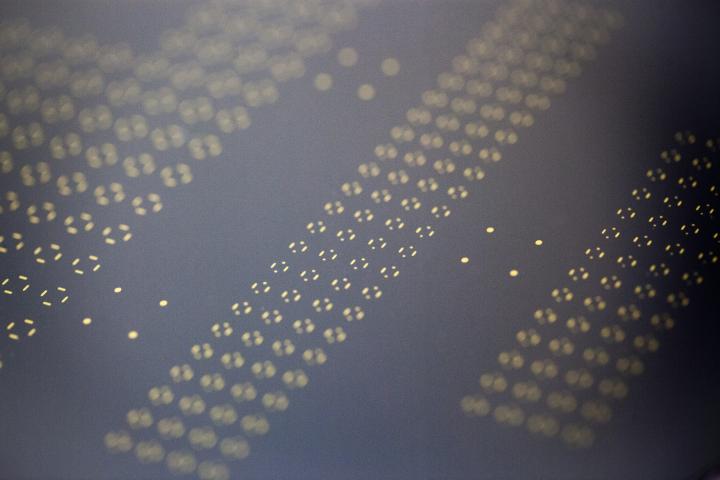

Credit: Paragraf

A recent University of Cambridge spin-out company, Paragraf, has started producing graphene – a sheet of carbon just one atomic layer thick – at up to eight inches in diameter, large enough for commercial electronic devices.

Paragraf is producing graphene ‘wafers’ and graphene-based electronic devices, which could be used in transistors, where graphene-based chips could deliver speeds more than ten times faster than silicon chips; and in chemical and electrical sensors, where graphene could increase sensitivity by a factor of more than 30. The company’s first device will be available in the next few months.

Graphene’s remarkable properties – stronger than steel, more conductive than copper, highly flexible and transparent – make it ideal for a range of applications. However, its widespread commercial application in electronic devices has been held back by the difficulties associated with producing it at high quality and at high volume. The conventional way of making large-area graphene involves using copper as a catalyst which contaminates the graphene, making it unsuitable for electronic applications.

Professor Sir Colin Humphreys from the Centre for Gallium Nitride in Cambridge’s Department of Materials Science and Metallurgy, along with his former postdoctoral researchers Dr Simon Thomas and Dr Ivor Guiney, developed a new way to make large-area graphene in 2015.

Using their method, the researchers were able form high-quality graphene wafers up to eight inches in diameter, beating not only other university research groups worldwide, but also companies like IBM, Intel and Samsung.

The three researchers spun out Paragraf in early 2018. Thomas is currently the company’s CEO and Guiney is its Chief Technology Officer, while Humphreys, who has recently moved to Queen Mary University of London, serves as Chair.

Paragraf has received £2.9 million in funding to support the development of its first commercial products and moved into premises in February 2018. The funding round was led by Cambridge Enterprise, the University’s commercialisation arm. Paragraf already employs 16 people and has filed eight patents.

“Paragraf has the potential to transform a wide range of industries, including electronics, energy and healthcare,” said Humphreys. “It will enable the brilliant basic science results achieved in laboratories worldwide using small graphene flakes to be commercially exploited in graphene-based devices and to realise the potential and benefits to society of graphene, the wonder material.”

###

The original research was funded by the Engineering and Physical Sciences Research Council (EPSRC).

Media Contact

Sarah Collins

[email protected]

Original Source

https:/