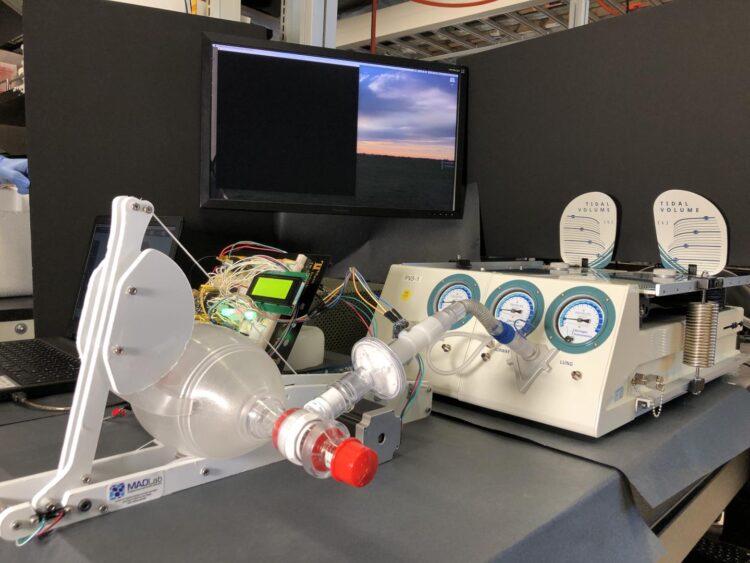

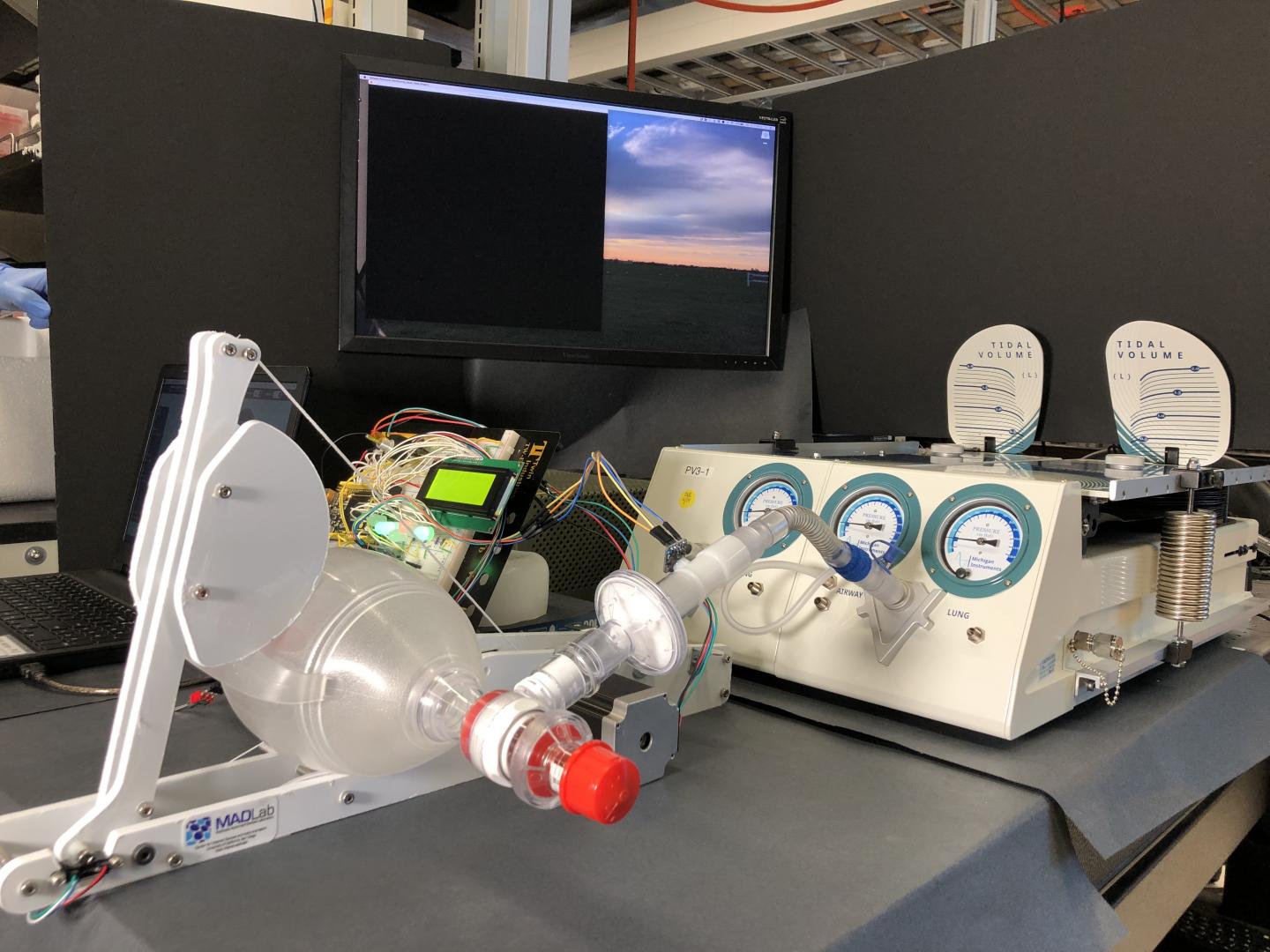

Credit: (Photo: University of California San Diego)

ARLINGTON, Va.–One of the most dangerous effects of coronavirus is the inability to breathe on your own–requiring the help of a ventilator to push air through your lungs.

Consequently, the severity of the coronavirus pandemic has resulted in ventilator shortages, causing some hospitals to assign multiple patients to one machine, limiting effective treatment.

To fight this threat, the Office of Naval Research (ONR) recently sponsored work to develop low-cost, easily built ventilator prototypes for both hospital and field settings. The ventilators would be valuable in emergency situations involving large patient surges and a lack of life-sustaining equipment.

“These ventilators could serve multiple naval scenarios,” said Dr. Timothy Bentley, a program manager in ONR’s Warfighter Performance Department. “Not just combat or tactical situations but also supporting humanitarian response during natural disasters and health crises. The ventilators can be constructed fast and are relatively simple to operate.”

This effort involves ONR; ONR Global, the command’s international arm; and the University of California San Diego (UCSD).

The prototypes are based on hand-held ventilators–composed of a mask and squeeze bag–used by paramedics to manually pump air into patients’ lungs. The UCSD team created enhanced ventilators with commercially available sensors, electronics and motors, allowing the machines to pump air automatically. The prototypes also can monitor whether air pressure is too high or low–a vital function, since dramatic pressure shifts can limit air flow and damage lung capacity.

The partnership stems from a recent nationwide Department of Defense (DoD)-held Hack-A-Vent Innovation Challenge. Participants designed ventilators that could be built quickly with locally sourced commercial parts, rapidly prototyped and easily operated.

Derek Ikehara–an ONR Global science advisor assigned to U.S. Naval Air Forces in San Diego–heard about the challenge and encouraged local performers to submit entries. One performer was Dr. James Friend, a UCSD engineering professor. Friend quickly assembled a team of engineering and medical students to build four prototypes using onsite manufacturing equipment and 3D printers.

Ikehara also contacted ONR’s Bentley, who agreed to sponsor the prototype development.

“This was a remarkable success story that occurred within only a few weeks,” said Ikehara. “ONR provided the funding within days of my request, UCSD did all the design work in-house and the result was multiple ventilators ideal for surge support in a crisis.”

The UCSD prototypes performed well during the Hack-A-Vent Innovation Challenge, finishing 22nd out of 172. UCSD currently is partnering with local manufacturing companies to produce the four ventilator types on a larger scale and distribute them to naval and civilian hospitals.

“This is an inspiring example of how ONR and the Navy recognize urgent emergencies and fund innovative solutions,” said Friend. “They said, don’t worry about money–worry about solving the problem. This allows us to respond to a pressing need and make a difference in society.”

###

Learn more about the UCSD ventilator effort at http://madvent.

Media Contact

David Smalley

[email protected]

Original Source

https:/