Hydroxyapatite, a mineral present in human bones, shows efficient decomposition of hazardous organic compounds when activated using mechanical stress

Credit: Image courtesy: Takashi Shirai from Nagoya Institute of Technology

One of the most prominent evils of rapid industrialization has been the emission of toxic pollutants into the surrounding biosphere, with often disastrous consequences for human beings. Several industrial processes, such as chemical manufacturing and printing, along with facilities such as power plants emit volatile organic compounds (VOCs) that are known to be cancer-causing and raise an important environmental issue in need of a solution. Traditionally, VOCs are controlled via a process called “catalytic oxidation,” in which they are converted into benign materials in the presence of noble metal (e.g. gold, silver, and platinum) nanoparticles. However, the process is expensive and requires a fine-tuning of nanoparticle characteristics. Thus, a catalytic process not requiring noble metal catalysts is highly desirable. While transition metals and their oxides are a possible alternative, they require complex syntheses and precise chemical composition control.

So, can we do better than this? Turns out, we can! A team of scientists led by Prof. Takashi Shirai from Nagoya Institute of Technology (NITech), Japan, reported a complete catalytic decomposition of VOC using an inorganic compound called “hydroxyapatite” (HAp), a naturally occurring form of the mineral calcium phosphate that makes up most of the human bone structure. “HAp is made of elements abundant in nature, is non-toxic and exhibits high biocompatibility. Our results, thus, opened up a new possibility for designing cheap, noble-metal-free catalysts for VOC control,” says Prof. Shirai.

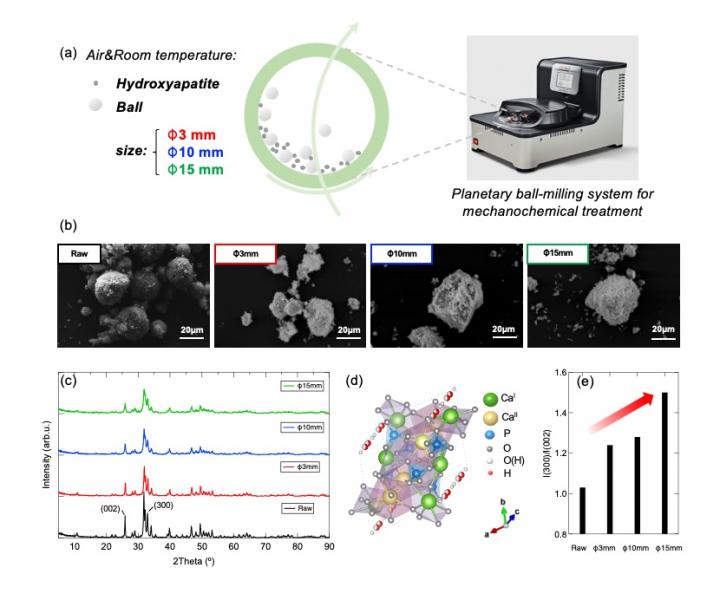

In a new study published in Scientific Reports, Prof. Shirai and his colleague Yunzi Xin from NITech now take things further by tailoring the “active surface” of HAp using a mechanochemical treatment under ambient conditions that leads to a highly efficient catalytic oxidation of VOC with 100% conversion to harmless compounds! Specifically, they mixed initial HAp with ceramic balls in a vessel and conducted “planetary ball milling” at room temperature and ambient pressure. This essentially altered the chemical structure of HAp and allowed for its selective tailoring by simply changing the ball size.

By using different ball sizes (3, 10, and 15 mm) to systematically vary the morphology, crystallinity, surface defects/oxygen vacancy, acidity/basicity, and VOC affinity of HAps, the scientists carried out their characterization using various techniques such as scanning electron microscopy, powder X-ray diffraction, Fourier transform infrared spectrometry, X-ray photoelectron spectroscopy, electron spin resonance analysis, surface acidity/basicity evaluation, and gas-flowing diffuse reflectance infrared Fourier transform spectroscopy.

They observed a predominance of oxygen vacancy formation in the PO43- (triply charged PO4) site along with an enhanced basic site population caused by a selective mechanochemical activation of the c-plane (plane perpendicular to the symmetry axis) of the hexagonal HAp crystal and attributed it to the excellent catalytic conversion of VOC to CO2/CO.

Moreover, they found that HAps treated with 3 mm balls showed superior catalytic activity over that treated with 10- and 15-mm balls, even though larger balls caused more defects and basicity. By looking at the surface absorption of a VOC, ethyl acetate, scientists attributed this anomaly to the inhibited absorption of ethyl acetate in HAp treated with larger balls, leading to suppressed catalysis.

The results have excited scientists about the future prospects of HAps. “We expect that our catalyst will contribute significantly to VOC controlling and environmental cleaning all over the world by next decade, achieving the sustainable goals of clean air and water, affordable energy, and climate action,” comments Prof. Shirai, excited.

Indeed, this is one huge step towards a more eco-friendly society!

###

Media Contact

Azusa Yabugami

[email protected]

Original Source

https:/

Related Journal Article

http://dx.