Pitt chemical engineers replicate feed, fight and flight responses in catalytic chemical reactions

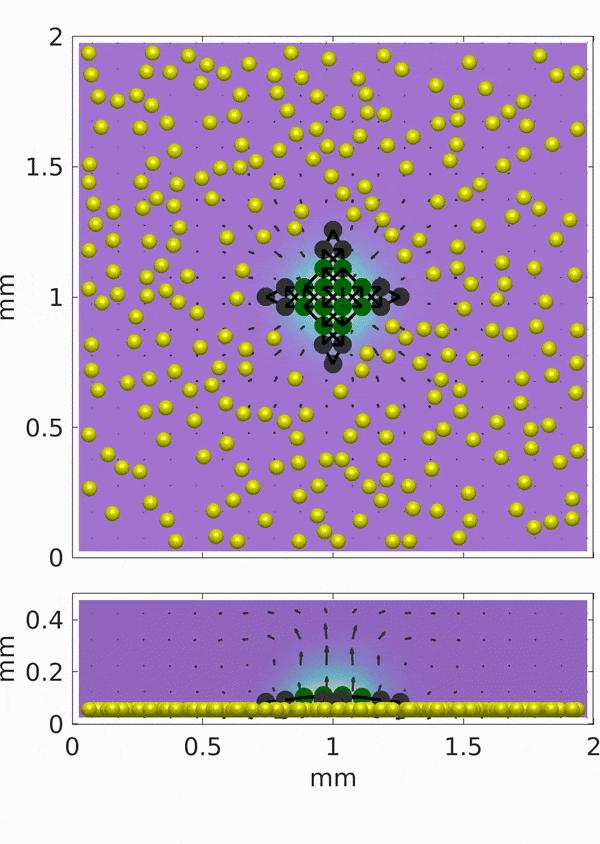

Credit: Abhrajit Laskar/Anna Balazs

PITTSBURGH (April 22, 2019) … Collaboration and competition are basic instincts among biological species, from the simplest single-celled organisms to reptiles, fish and primates, as well as humans. This dynamic behavior – the result of millions of years of evolution – is difficult to replicate in synthetic systems. However, chemical engineers at the University of Pittsburgh Swanson School of Engineering have recreated these responses in an environment of microscopic particles, sheets, and catalysts, effectively mimicking responses of feeding, fighting, and fleeing.

Their research, “Collaboration and completion between active sheets for self-propelled particles,” was published this week in Proceedings of the National Academy of Sciences (PNAS, DOI: 10.1073/pnas.1901235116). Principal investigator is Anna C. Balazs, the John A. Swanson Chair and Distinguished Professor of Chemical and Petroleum Engineering at the Swanson School. Lead author is Abhrajit Laskar, and co-author is Oleg E. Shklyaev, both post-doctoral associates.

As a lead-up to this work, Dr. Balazs et al used computational modeling to design chemically active sheets that were able to wrap, flap and creep in a fluid-filled microchamber, leveraging the potential to create flexible or “squishy” robots for fluidic environments. For the PNAS article, the researchers designed fluidic systems that shape the catalyst-coated sheets into a form resembling a crab with four “claws,” creating the predator that can chemically “hunt” its particle prey.

“As we develop future robotics and smart devices, it’s important to understand the limits to imitating biological functions in human-made machines. It is also critical to understand whether artificial systems can collaborate or compete for resources,” Dr. Balazs explained. “If we can replicate this interdependency, we can help establish the foundation for robots or other devices to work together toward a common goal.”

To affect this behavior, Balazs and her associates utilized the catalyst on the sheets to convert reactants to products within a microchamber. This reaction creates variations in the chemical composition and fluid density, which change the two-dimensional sheets into 3D “crabs” and propel both the crabs and the particles in the fluid. As the crabs generate chemical gradients in one area, the particles respond by attempting to “flee” from this area, forming a highly interdependent system.

This interdependency also impacted the environment when a second crab was added to the fluid – once the reactant was introduced, the two crabs mimicked cooperation to “share” particles. However, if a larger crab was introduced, it would compete with the smaller shapes to capture all the particles for itself.

“In some cases, the big crab can’t catch the small particles, but when we add more crabs they appear to collaborate like a pack of wolves,” Dr. Shklyaev explains. “Likewise, when an even larger predator enters the microchamber, the “hunger” it generates with a larger catalytic surface area will dominate the behavior of the smaller predator sheets.”

Dr. Laskar says that the simplicity of this system is that the only programming involved is the introduction of the chemical reagent into the system.

“Once we added a reactant into the microchamber, all the biomimetic behaviors occurred spontaneously,” he said. “We can then tailor the extent to which the particles respond to chemical gradients, because different particles will respond in different ways. So changing the property of even one type of object alters the interdependency of the whole system.”

According to Dr. Balazs, the new findings indicate the ability to control activity within the microchamber in space and time, thereby enabling the sheets to respond to different commands only by changing the reactants added to the solution.

“Our computations reveal the ability to direct microscopic objects to perform specific functions, such as transporting cells or building complex structures,” she said. “These design rules have the potential to diversify the functionality of microfluidic devices, allowing them to accomplish significantly more complex tasks.”

###

Acknowledgements: This research is made possible through funding from NSF Grant 1740630, CCI Phase I, Center for Chemo-Mechanical Assembly, and computational facilities at the Center for Research Computing at the University of Pittsburgh.

Media Contact

Paul Kovach

[email protected]

Original Source

https:/

Related Journal Article

http://dx.