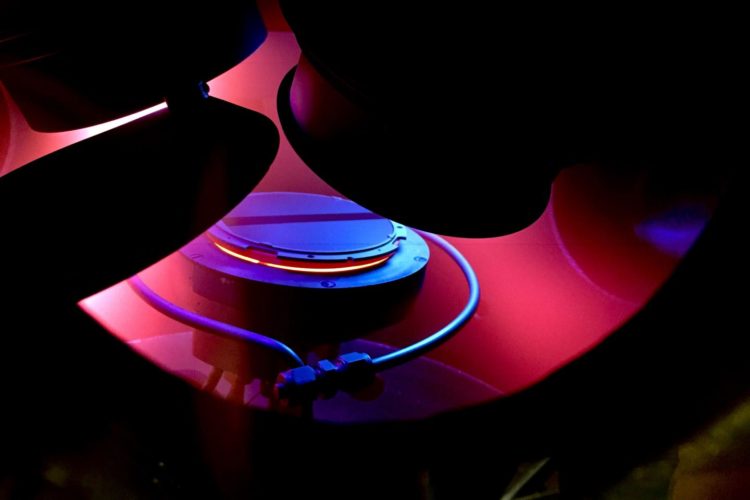

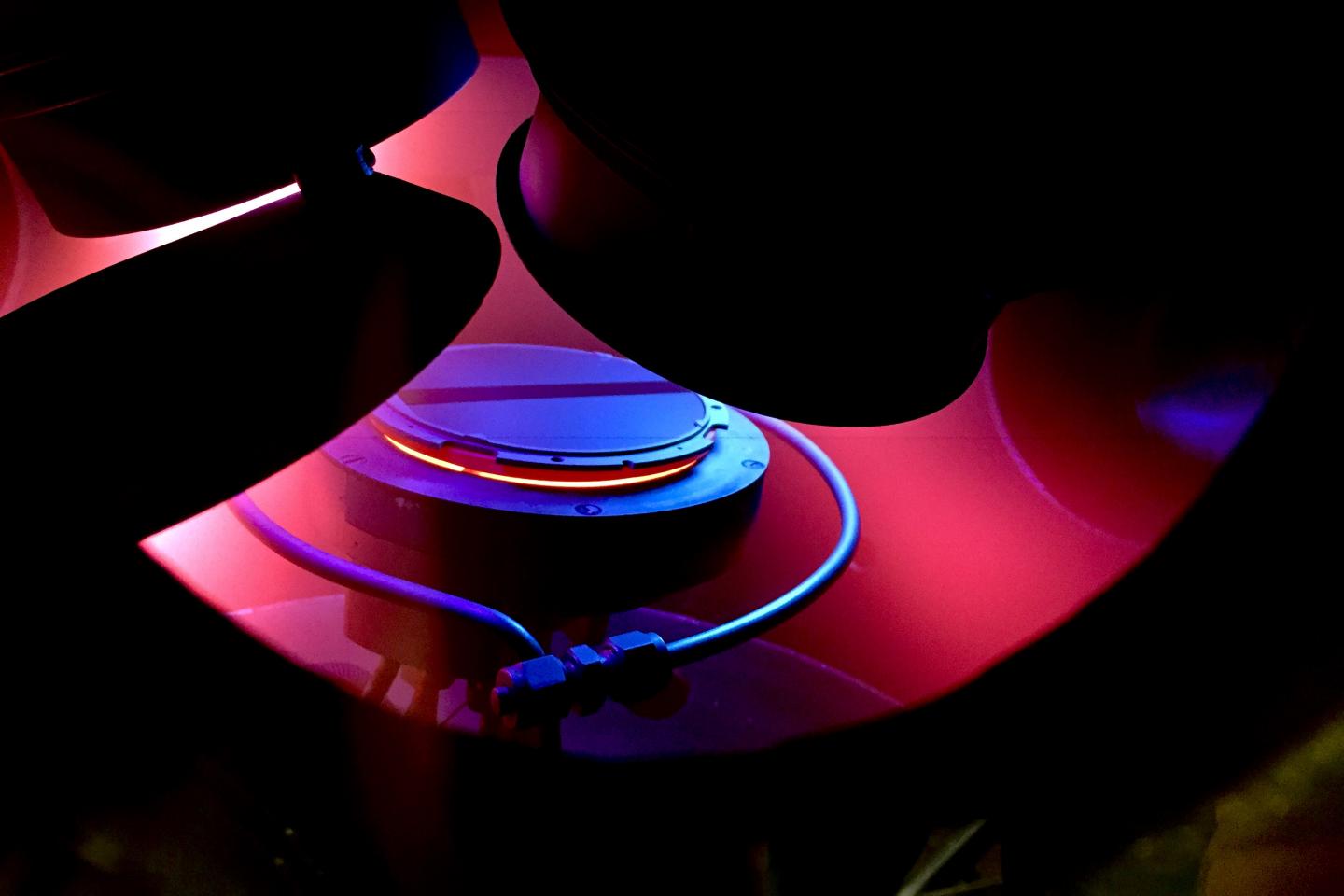

Material research

Credit: © Lars Banko

Porous or dense, columns or fibres

During the manufacture of thin films, numerous control variables determine the condition of the surface and, consequently, its properties. Relevant factors include the composition of the layer as well as process conditions during its formation, such as temperature. All these elements put together result in the creation of either a porous or a dense layer during the coating process, with atoms combining to form columns or fibres. “In order to find the optimal parameters for an application, it used to be necessary to conduct countless experiments under different conditions and with different compositions; this is an incredibly complex process,” explains Professor Alfred Ludwig, Head of the Materials Discovery and Interfaces Team.

Findings yielded by such experiments are so-called structure zone diagrams, from which the surface of a certain composition resulting from certain process parameters can be read. “Experienced researchers can subsequently use such a diagram to identify the most suitable location for an application and derive the parameters necessary for producing the suitable layer,” points out Ludwig. “The entire process requires an enormous effort and is highly time consuming.”

Algorithm predicts surface

Striving to find a shortcut towards the optimal material, the team took advantage of artificial intelligence, more precisely machine learning. To this end, PhD researcher Lars Banko, together with colleagues from the Interdisciplinary Centre for Advanced Materials Simulation at RUB, Icams for short, modified a so-called generative model. He then trained this algorithm to generate images of the surface of a thoroughly researched model layer of aluminium, chromium and nitrogen using specific process parameters, in order to predict what the layer would look like under the respective conditions.

“We fed the algorithm with a sufficient amount of experimental data in order to train it, but not with all known data,” stresses Lars Banko. Thus, the researchers were able to compare the results of the calculations with those of the experiments and analyse how reliable its prediction was. The results were conclusive: “We combined five parameters and were able to look in five directions simultaneously using the algorithm – without having to conduct any experiments at all,” outlines Alfred Ludwig. “We have thus shown that machine learning methods can be transferred to materials research and can help to develop new materials for specific purposes.”

###

Funding

The research was funded by the German Research Foundation under the umbrella of Collaborative Research Centre/Transregio 87 “Pulsed high power plasmas for the synthesis of nanostructural functional layers”, subproject C2.

Original publication

Lars Banko, Yury Lysogorskiy, Dario Grochla, Dennis Naujoks, Ralf Drautz, Alfred Ludwig: Predicting structure zone diagrams for thin film synthesis by generative machine learning, in: Communications Materials, 2020, DOI: 10.1038/s43246-020-0017-2

Press contact

Prof. Dr. Alfred Ludwig

Materials Discovery and Interfaces

Institute for Materials

Department of Mechanical Engineering

Ruhr-Universität Bochum

Germany

Email: [email protected]

Media Contact

Prof. Dr. Alfred Ludwig

[email protected]

Original Source

https:/

Related Journal Article

http://dx.