EPIC project aims at the energetic, economic, and ecological optimization of production

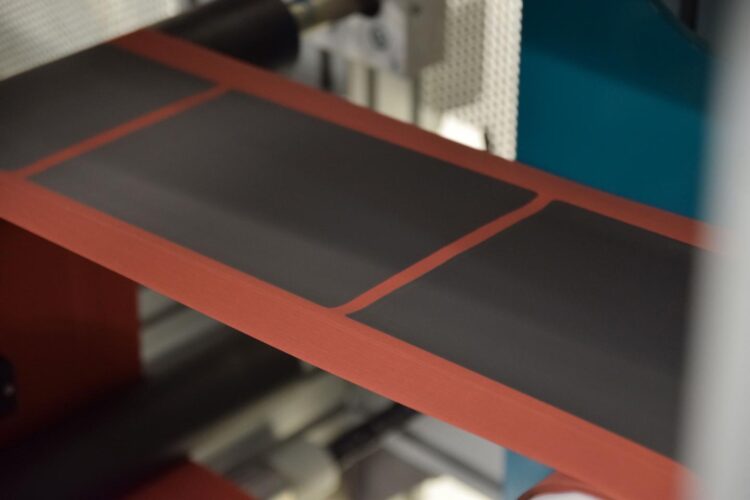

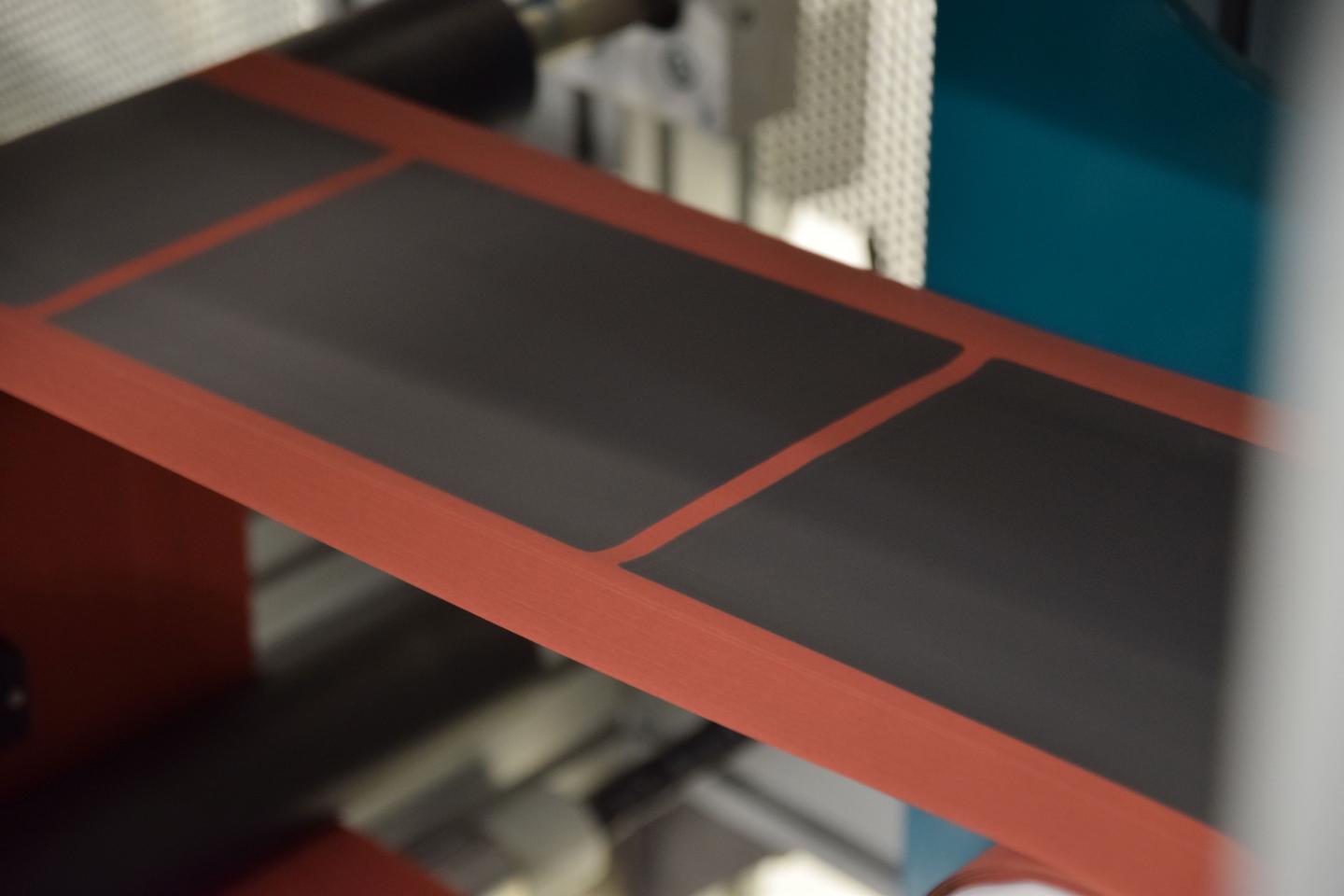

Credit: (Photo: Ralf Diehm/KIT)

Extension of electric mobility results in an increasing demand for suitable batteries. The new EPIC project coordinated by Karlsruhe Institute of Technology (KIT) is aimed at accelerating the drying of high-quality electrodes for lithium-ion batteries, increasing the energy efficiency of this process and, hence, reducing the cost of production. Innovative drying management of electrodes reduces costs of battery production, improves the environmental performance, and strengthens the position of Germany as a location of production. EPIC is funded by the Federal Ministry of Research with EUR 3 million.

The quality of battery cells based on lithium ions for future electric cars, for instance, decisively depends on the electrode layers. These active materials store the energy. Both the anode and the cathode material are applied in a very thin layer of a water- or solvent-based paste onto a conducting foil made of copper and aluminum, respectively. Production of electrodes takes a long time and increases investment and production costs. Researchers of the Thin Film Technology (TFT) group of KIT have now developed an innovative coating process, by means of which electrodes for lithium-ion batteries can be produced as quickly as never before. The following process steps, drying with structural development and a final drying step, currently represent the bottleneck of the process that prevents the electrode production speed from being increased. “But it is here, where costs of battery cell production can be reduced considerably,” the TFT researchers explain.

Integrated Analysis of the Process Steps

Reducing overall battery production costs and in particular the energy costs for electrode drying by at least 20% are the goals of the project “Erhöhung der Durchsatzgeschwindigkeit in der Elektrodenproduktion durch ein innovatives Trocknungsmanagement” (Increasing the speed of electrode production by innovative drying management), EPIC for short. Scientists work on increasing the drying speed by at least 50%, while maintaining or even further enhancing quality and long-term stability of the electrodes. “It is important to analyze the individual process steps together and to consider interactions,” says Professor Wilhelm Schabel. The Thin Film Technology (TFT) group headed by him coordinates the project. Other partners of EPIC are Professor Jürgen Fleischer from the wbk Institute of Production Science of KIT and researchers from the Center for Solar Energy and Hydrogen Research Baden-Württemberg (ZSW) in Ulm and the Technical University of Braunschweig. Within the framework of the ProZell II research cluster, EPIC is funded by the Federal Ministry of Education and Research (BMBF) with a total of EUR 3 million for a duration of three years. The project started on August 1.

EPIC does not only focus on innovative drying technologies that combine a high energy efficiency with high quality, but also on an optimal moisture management for the materials used along the process chain, from drying to cell assembly. TFT studies conventional drying processes, use of high-power radiators, and drying management in general. “Higher coating speeds are particularly attractive when drying time can be reduced and the expensive drying line does not have to be extended,” says Dr. Philip Scharfer, TFT.

The wbk studies drying directly in the cell stack prior to electrolyte filling as well as adjustment of the required cell moisture without prior drying in the cell stack directly before electrolyte filling. In any case, wbk, in cooperation with researchers from the Technical University of Braunschweig, evaluates how the drying intensity and duration influence cell properties. The ZSW, Ulm, will model on its line for the production of industry-scale batteries the exposure to moisture under a controlled production atmosphere on a scale comparable to that of series production.

Networking Strengthens Battery Research

The different approaches to production will be evaluated by the project partners using suitable process-cost models. Then, recommendations will be made for transferring the process to the industrial scale. Apart from energy and resource efficiency as well as battery cell quality, environmental compatibility will also be considered. TFT develops its technologies for electrode production – also for future new materials systems – at the Center for Electrochemical Energy Storage Ulm & Karlsruhe (CELEST), one of the largest battery research platforms worldwide. Latest findings in production technology will be incorporated directly in the Post Lithium Storage (POLiS) cluster of excellence, in which KIT will develop future batteries together with Ulm University and ZSW.

###

More about the KIT Energy Center: http://www.

Contact for this press release: Martin Heidelberger, Editor/Press Officer, Phone: +49 721 608-41169, martin [email protected]

Being “The Research University in the Helmholtz Association”, KIT creates and imparts knowledge for the society and the environment. It is the objective to make significant contributions to the global challenges in the fields of energy, mobility, and information. For this, about 9,300 employees cooperate in a broad range of disciplines in natural sciences, engineering sciences, economics, and the humanities and social sciences. KIT prepares its 24,400 students for responsible tasks in society, industry, and science by offering research-based study programs. Innovation efforts at KIT build a bridge between important scientific findings and their application for the benefit of society, economic prosperity, and the preservation of our natural basis of life. KIT is one of the German universities of excellence.

Media Contact

Monika Landgraf

[email protected]

Original Source

https:/