Kanazawa University-led researchers simulate the industrial process of stamping features into metal sheets without causing the sheets to tear, twist, or bend to aid fabrication of tools to create metal parts for products such as cars

Credit: Kanazawa University

Kanazawa, Japan – The process of stamping metal sheets to create parts used in automotive products such as car doors has received a virtual upgrade in the form of a simulation method devised by Kanazawa University-based researchers. Their simulation can be used to optimize a metal stamping press in its conceptual design stage, thus reducing the costs of physically trialing designs. This method is not only cost-effective, but also more comprehensive than past simulation methods.

To improve fuel consumption, automotive manufacturers have increasingly been looking to fabricate cars using lighter materials than traditional steel. High-strength steel is considered a lightweight alternative, but when sheets of high-strength steel are stamped into shape to fabricate car parts, they are more likely to bend, tear, wrinkle, or become too thin in places compared with parts made of traditional steel.

In a competitive automotive market, it is more important than ever to carry out simulations in advance to optimize tools before building and testing them. Otherwise, the tools may need to be altered over a lengthy and costly period of trial-and-error until they can successfully fabricate high-quality parts. Many components of the tool have an effect on the final product and could therefore be optimized via simulations; however, current simulations are not comprehensive and rarely consider the shape of the stamping stencil (termed the “blank shape”) that the metal sheet is punched through to form the desired shape. Additionally, much research in this area focuses on stamping simple bar- or U-shapes.

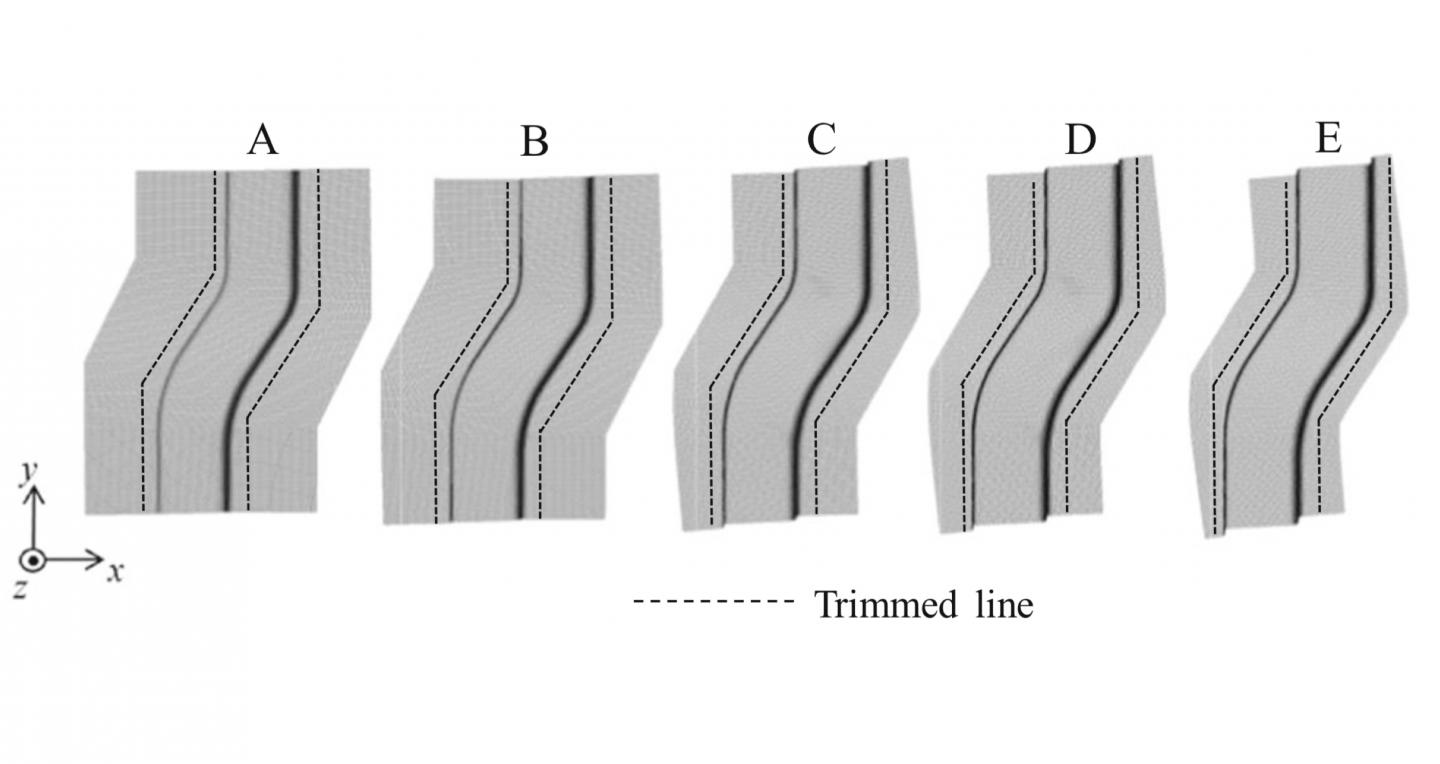

“We simulated the stamping of S-shapes into sheet metal. Unlike U-shapes, the stamping of S-shapes can cause the metal parts to twist out of shape, allowing us to study ways of reducing twisting springback,” study co-author Ryoto Ishizuki says.

The researchers came up with a novel way of reducing the twisting of metal sheets by optimizing the shape of the blank shape while also minimizing tearing and wrinkling of the metal sheet. They also simulated how much force to use to clamp the metal sheet in place in the so-called “blank holder” and how it should be varied during the punching process to achieve the best results.

“Sequential approximate optimization using a radial basis function network allowed us to efficiently optimize the blank shape and variable blank holder force trajectory,” first author Satoshi Kitayama says.

Reducing the propensity of high-strength steel parts to twist and bend out of shape after undergoing stamping is a key concern within the car manufacturing industry. The results of this study are therefore anticipated to significantly increase the quality of stamped metal parts.

###

Media Contact

Tomoya Sato

[email protected]

Related Journal Article

http://dx.