In a groundbreaking advancement at the crossroads of materials science and bioengineering, researchers have unveiled an innovative method for fabricating highly precise, three-dimensional conductive hydrogels tailored for next-generation soft bioelectronic devices. The study, spearheaded by Buzio, Gini, Schneider, and their colleagues, introduces the use of two-photon lithography to sculpt PEDOT:PSS/gelatin composite hydrogels into complex microarchitectures, a leap forward aimed at bridging the interface between biological tissues and electronic systems.

The essence of this approach lies in combining the electrical conductivity of PEDOT:PSS (poly(3,4-ethylenedioxythiophene):poly(styrenesulfonate)) with the biocompatibility and mechanical compliance of gelatin, a natural polymer derived from collagen. This hybrid material embodies an ideal physiological milieu, offering softness and stretchability compatible with living tissues while sustaining the electron transport integral to bioelectronic functionality. Yet, achieving detailed spatial control over the microstructure of such composite hydrogels has posed a significant challenge—until now.

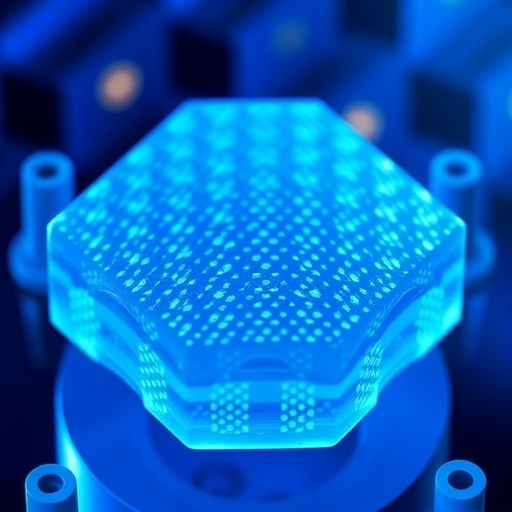

Two-photon lithography, a high-resolution 3D printing technique that leverages nonlinear absorption of femtosecond laser pulses, enables the direct writing of micro- and nanoscale features inside photosensitive materials with unprecedented precision. This team adeptly harnessed the power of two-photon lithography to induce localized cross-linking of the gelatin matrix in the presence of PEDOT:PSS, thereby creating conductive pathways embedded within a hydrated, gel-like environment. The resulting constructs possess tailored geometries at sub-micrometer resolution, a scale critical for interfacing with cellular components and neuronal networks.

The meticulous orchestration of photopolymerization parameters allowed the researchers to finely tune the electrical properties and mechanical stiffness of the hydrogels. By adjusting laser exposure and material formulations, they achieved a delicate balance—maximizing conductivity while maintaining tissue-like softness and ensuring aqueous stability. Such control amplifies the potential application scope, from soft sensors conforming to organ surfaces to implantable devices that facilitate seamless electrophysiological monitoring.

Beyond material composition and fabrication, the study provides extensive characterization of the hydrogels’ biocompatibility and functionality. In vitro assays demonstrated that cultured cells exhibit superior adhesion and viability on these microstructured hydrogels compared to traditional rigid electrodes. This biocompatibility is pivotal for chronic implantation, where minimizing inflammatory responses and promoting cellular integration are paramount for device longevity and performance.

The team further showcased the potential of their conductive hydrogels in soft bioelectronic circuits by integrating microelectrode arrays capable of detecting electrical signals with high sensitivity and spatial resolution. Such devices could revolutionize biomedical diagnostics and therapeutics by enabling real-time, minimally invasive monitoring of neural activity, cardiac rhythms, or muscle contractions. The flexible nature of the hydrogels facilitates intimate contact with soft tissues, mitigating mechanical mismatch that commonly impairs electrode-tissue interfaces.

An especially compelling aspect of this research is its modularity. The two-photon lithography technique permits the fabrication of complex three-dimensional architectures, including multilayered and branched structures, that mimic the intricate extracellular matrix found in vivo. This biomimetic capability opens avenues for the creation of advanced neural interfaces, biosensors, and tissue engineering scaffolds that actively interact with biological systems rather than merely recording from them.

This combination of electrical conductivity and biofunctionality within a 3D microfabrication paradigm holds promise for advancing precision medicine. For instance, soft neural probes constructed from these hydrogels could be customized to individual patient anatomy and disease states, enabling tailored interventions with enhanced efficacy and reduced side effects. Furthermore, incorporation of functional biomolecules or drug reservoirs within the hydrogel matrix could transform these platforms into multifunctional therapeutic devices.

In addition to health care, the implications extend to wearable electronics and soft robotics, where flexible, stretchable sensors capable of detecting electrophysiological signals or mechanical forces in real-time are in high demand. The scalable production of such conductive hydrogels may pave the way for consumer devices embedded into fabrics or skin-mounted patches that are comfortable, biocompatible, and mechanically resilient.

The study addresses long-standing challenges in soft bioelectronics by overcoming the limitations posed by traditional electrode materials such as metals and silicon, which are often rigid and prone to degradation in physiological environments. Moreover, the utilization of gelatin, an abundant and biodegradable biopolymer, aligns with growing sustainability trends in material science, offering eco-friendly alternatives to synthetic polymers.

Detailed electrical testing revealed that the fabricated hydrogels sustain stable conductivity under cyclic mechanical strain, an essential characteristic for devices implanted in dynamic biological environments where deformation is frequent. Such robustness in performance underscores the material’s suitability for real-world medical applications requiring durability and reliability over extended periods.

Furthermore, the ability to pattern conductive elements in three dimensions enables the integration of multiple sensing modalities within compact volumes, enhancing the functional density of bioelectronic implants without increasing their physical footprint. This feature is critical for enabling high-resolution mapping of biological signals, facilitating new insights into complex physiological processes at cellular and tissue levels.

The underlying chemical interactions governing the cross-linking process and conductivity retention were elucidated using spectroscopic and microscopic analysis. These insights provide a foundation for future refinement of the hydrogel composition and fabrication parameters, potentially leading to even higher conductivities, enhanced mechanical properties, or new functionalities such as responsiveness to environmental stimuli.

Looking ahead, this innovative 3D micropatterning strategy sets the stage for interdisciplinary collaborations spanning materials science, neurobiology, biomedical engineering, and clinical medicine. Its translation from lab-scale demonstrations to practical medical devices could revolutionize how clinicians diagnose, monitor, and treat diseases, particularly those related to neural and cardiac dysfunction.

The convergence of soft hydrogel materials with precise laser-based micropatterning technologies heralds a new era in bioelectronics where devices are not just tools but integrated partners in the biological ecosystem. Through this synergy, the boundary between living tissue and electronic circuitry begins to blur, opening transformative possibilities in health care, human-machine interfaces, and beyond.

As this research continues to evolve, the scientific community eagerly anticipates the forthcoming clinical validations and commercial adaptations that will bring these conductive hydrogels from experimental innovation to everyday medical reality. The study by Buzio and colleagues, published in npj Flexible Electronics, stands as a landmark contribution illuminating the path toward truly seamless bioelectronic integration.

Subject of Research: 3D micropatterning of PEDOT:PSS/Gelatin conductive hydrogels for applications in soft bioelectronics.

Article Title: 3D micropatterning of PEDOT:PSS/Gelatin conductive hydrogels via two-photon lithography for soft bioelectronics.

Article References:

Buzio, M., Gini, M., Schneider, T.C. et al. 3D micropatterning of PEDOT:PSS/Gelatin conductive hydrogels via two-photon lithography for soft bioelectronics. npj Flex Electron (2026). https://doi.org/10.1038/s41528-026-00529-5

Image Credits: AI Generated

Tags: 3D conductive hydrogelsadvanced materials for bioelectronicsbiocompatible hydrogel developmentbridging biological tissues and electronicsconductive pathways in hydrogelsgelatin-based composite hydrogelsmicroarchitecture in bioengineeringnext-generation biomedical devicesPEDOT:PSS composite materialsprecision 3D printing techniquessoft bioelectronics innovationtwo-photon lithography applications