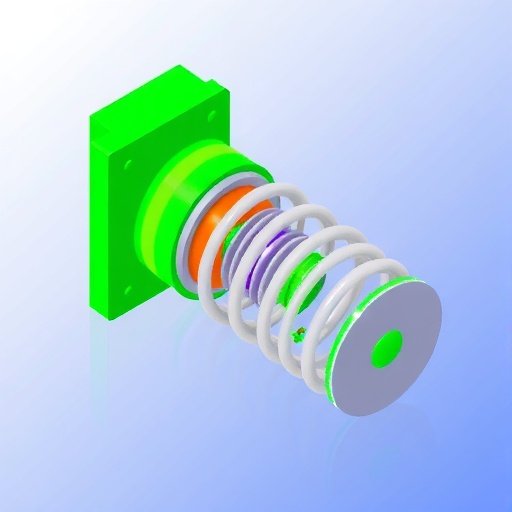

In an evolving automotive landscape, the quest for enhanced performance, comfort, and safety leads engineers to explore innovative designs and technologies. One area of significant focus is the development of air-spring-dampers—a component that plays a crucial role in the suspension systems of vehicles. These systems are responsible for maximizing rider comfort while ensuring vehicle stability and handling. This delicate balance requires precision engineering, making the design process a critical aspect of vehicle development.

Recent advancements have been made by a team of researchers led by Schnieders, Rexer, and Jericho, who aim to revolutionize the way air-spring-damper systems are designed. Their groundbreaking work presents a modular simulation framework that allows engineers to evaluate and optimize different configurations and parameters of air-spring-dampers seamlessly. Such innovations cater to the specific needs of automotive manufacturers and engineers, effectively streamlining the design process.

The modular nature of the simulation framework permits flexibility, allowing users to mix and match different elements of air-spring-damper systems. This adaptability is crucial because the unique driving conditions and preferences of end-users can vary widely. By creating a system that accommodates a variety of configurations, the researchers provide a powerful tool for optimizing performance across different vehicle types and use cases.

In addition to providing flexibility, the simulation framework is designed to enhance accuracy in modeling the dynamic behavior of air-spring-damper systems. Engineers can simulate a wide range of driving scenarios, from smooth highway cruising to challenging off-road conditions, giving them insights into how different configurations will perform under various circumstances. This level of sophistication was previously unattainable with traditional approaches, which often relied on inflexible design parameters and limited scope for testing.

Another notable aspect of this work lies in the efficiency it brings to the design workflow. The modular simulation framework can integrate with existing engineering tools, promoting an efficient design cycle that reduces time and resource expenditure. By combining various testing scenarios and configuration options, engineers can identify the optimal designs more quickly than ever before, accelerating the path from conception to production.

This capability is particularly crucial in today’s fast-paced automotive market, where competition is fierce. Manufacturers are under pressure to innovate while keeping costs down and ensuring quality. The researchers’ modular approach empowers engineers to conduct rapid prototyping, allowing for quick iterations and refinements in design without the need for extensive physical testing. This agility enhances manufacturers’ ability to adapt to changing market demands and consumer preferences.

Moreover, the study of air-spring-damper systems opens up pathways toward sustainability in automotive design. By optimizing these components, manufacturers can achieve better fuel efficiency and reduced emissions, aligning with the global push for greener automotive solutions. The modular simulation framework directly contributes to these goals by enabling engineers to explore lightweight materials and design efficiencies that could lead to more sustainable vehicles.

The research team utilized cutting-edge algorithms and mathematical models to develop their framework, providing a comprehensive toolkit for engineers. By leveraging advancements in computational technology, they empower engineers to explore complex interactions between suspension components, vehicle dynamics, and driver inputs in a virtual environment. The result is a more informed design process that takes into account not only mechanical interactions but also user experience.

As this research progresses and garners attention from the automotive industry, it holds the potential to redefine industry standards for air-spring-damper design. Manufacturers who adopt this innovative framework will likely benefit from improved product offerings, better customer satisfaction, and enhanced market competitiveness. Furthermore, this research could pave the way for future innovations in suspension technology that continue to provide a smoother, safer ride for consumers.

In conclusion, the modular simulation framework presented by Schnieders and colleagues signifies a major advancement in the realm of automotive engineering. By integrating flexibility, accuracy, and efficiency, this tool represents a paradigm shift in how air-spring-damper systems are envisioned and designed. As the automotive industry continues to evolve, such innovative frameworks will be indispensable in meeting the challenges of modern vehicle development.

While manufacturers stand to gain much from this research, the ultimate beneficiaries will be consumers. Vehicles equipped with optimized air-spring-dampers will enhance ride quality, safety, and performance, enabling a more enjoyable driving experience. The work of Schnieders and his team reminds us that as technology advances, so too does our capability to craft superior automotive solutions.

In the near future, we can expect this research to spark further exploration into advanced suspension technologies—perhaps even leading to developments in fully autonomous vehicle systems. As innovation begets innovation, the implications of such research could truly reshape the landscape of mobility.

As we look to the future, the potential impacts of this work on automotive design and manufacturing become increasingly significant. By improving air-spring-damper systems, we may very well be stepping toward a new era of vehicles that harmonize performance with environmental responsibility. The ongoing exploration of such technologies heralds a promising future in which driving communities can enjoy enhanced efficiency without compromising on comfort or safety.

This research, therefore, stands not just as a standalone advancement but as a cornerstone for future studies. The collaboration and teamwork exhibited in this exploration exemplify how collective knowledge and innovation can lead to breakthroughs that benefit both the industry and society at large.

In conclusion, the modular simulation framework for air-spring-dampers represents a vital development in automotive engineering, with the potential to change how vehicles are designed and experienced. As the findings from this research unfold within the industry, drivers may soon enjoy the fruits of advanced engineering and design.

In summary, the automotive industry continues to grow and evolve, driven by demand for cutting-edge technology and improved performance. The work completed by Schnieders, Rexer, and Jericho reflects the importance of adapting to these changes, utilizing new tools and methodologies to maximize efficiency and ultimately enhance the driving experience.

Subject of Research: Development of a modular simulation framework for air-spring-dampers in automotive engineering.

Article Title: Modular simulation framework for the design of air-spring-dampers.

Article References:

Schnieders, M., Rexer, M., Jericho, C. et al. Modular simulation framework for the design of air-spring-dampers.

Automot. Engine Technol. 10, 5 (2025). https://doi.org/10.1007/s41104-025-00148-8

Image Credits: AI Generated

DOI: https://doi.org/10.1007/s41104-025-00148-8

Keywords: Air-spring-dampers, modular simulation framework, automotive engineering, vehicle dynamics, suspension technology, design optimization, efficiency, sustainability.

Tags: air-spring-damper designair-spring-damper performance evaluationautomotive manufacturer solutionsautomotive suspension systemscustomizable suspension componentsengineering advancements in suspensionflexible design tools for engineersinnovative design technologiesmodular simulation frameworkprecision engineering in automotiverider comfort and vehicle stabilityvehicle performance optimization