Rice drying stands as a pivotal process in the post-harvest handling of one of the world’s most essential staple foods. Freshly harvested rice typically contains a high level of moisture, generally ranging from 22% to 30%, which, if not rapidly reduced below a critical threshold of 14%, can initiate biochemical degradation. Elevated moisture levels promote enhanced enzymatic activity and the growth of molds and fungi that can severely compromise the quality, shelf life, and safety of rice products. Ensuring effective drying is thus not only a matter of preserving food quantity but also safeguarding food security on a global scale.

Among various drying technologies, the deep bed dryer has emerged as a notably efficient system. Utilizing convective heat transfer, this drying apparatus works by passing air through a thick layer of grain to reduce moisture content gradually and evenly. The operational success of a deep bed dryer hinges heavily on the design of its aeration system, which must deliver airflow uniformly across the entire mass of paddy rice. Any uneven distribution risks localized over-drying—leading to grain fissures—or insufficient drying areas where microbial contamination thrives. Despite its critical importance, designing an aeration system that achieves optimal uniformity of airflow is a complex engineering challenge.

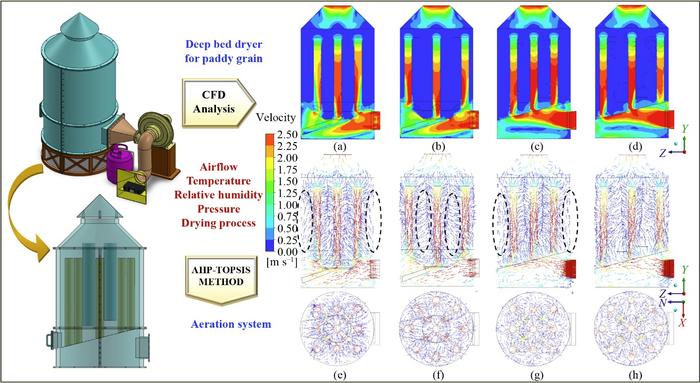

Researchers from Indonesia’s IPB University, led by Diswandi Nurba, have recently addressed this challenge by applying an innovative approach that combines Computational Fluid Dynamics (CFD) simulations with an advanced multi-criteria decision-making framework known as the AHP-TOPSIS method. This combined technique allows the detailed examination of multiple critical parameters affecting drying performance, including airflow velocity, pressure distribution, temperature gradients, and relative humidity variation within the drying chamber. Such multiphysical factors interact in complex ways, which traditional empirical design methods often fail to capture holistically.

.adsslot_PBhXA1RGVa{width:728px !important;height:90px !important;}

@media(max-width:1199px){ .adsslot_PBhXA1RGVa{width:468px !important;height:60px !important;}

}

@media(max-width:767px){ .adsslot_PBhXA1RGVa{width:320px !important;height:50px !important;}

}

ADVERTISEMENT

The study examined four distinct aeration system configurations differentiated by two main design elements: floor shape and air pipe formation. The floors were either conical or sloping, while the pipes supplying airflow were arranged in rectangular or circular cross-sections. Each design was subjected to extensive CFD modeling, which provided high-resolution visual and quantitative data on internal airflow dynamics. The simulated environment modeled airflow patterns penetrating the rice bed, capturing velocity fields, pressure variance, and the corresponding thermal and humidity distribution patterns.

To transcend the limitation of analyzing single performance metrics, the researchers employed a hybrid method integrating the Analytic Hierarchy Process (AHP) and the Technique for Order Preference by Similarity to Ideal Solution (TOPSIS). This approach enabled them to assign weighted importance to multiple criteria extracted from the simulations, creating a composite evaluation index for each design. By doing so, they could objectively rank the aeration systems based on comprehensive operational effectiveness rather than isolated parameters, embracing the inherent multidimensionality of drying performance.

The results identified a clear optimal configuration: a “sloping floor” combined with a “circular pipe formation,” dubbed Model 4. The sloping floor design mitigated airflow obstruction near the base of the dryer, facilitating freer and more even air diffusion into the rice bed. Meanwhile, circular pipes delivered airflow more radially and uniformly, eliminating the airflow dead zones commonly seen with rectangular pipe arrangements. These synergistic effects substantially reduced fluctuations in airflow velocity and temperature and humidity disparities within the drying chamber, creating a consistently favorable microenvironment for rice drying.

Further simulations reflecting a typical 5-hour drying period demonstrated that Model 4 significantly outperformed its counterparts, achieving a drying rate of approximately 2.22% moisture reduction per hour. This led to a final average rice moisture level of 13.9%, diminishing the risks linked to both spoilage and quality deterioration. Additionally, the uniformity of drying reduced the occurrence of over- or under-dried pockets, which often degrade overall grain quality and market value. This finding is particularly consequential for tropical regions where drying must occur swiftly to combat ambient heat and humidity challenges.

This investigation underscores the profound advantages of integrating visual simulation tools and multidimensional evaluation methods in agricultural engineering. Unlike traditional dryer design efforts that often rely on trial-and-error or focus narrowly on single variables such as airflow rate, this comprehensive approach delivers actionable insights supported by quantitative evidence. It clarifies the spatial distribution of airflow strength and consistency, highlighting precisely where improvements are needed to enhance drying uniformity.

Moreover, incorporating CFD and AHP-TOPSIS not only enhances precision but also streamlines the design process, reducing reliance on costly and time-consuming experimental prototypes. Computational modeling expedites the iterative development of aeration systems by enabling virtual testing scenarios under diverse operational conditions, thus saving resources while maximizing design optimization possibilities. Multi-criteria decision-making frameworks further enable decision-makers to balance competing objectives efficiently, ensuring the chosen system design meets practical constraints without sacrificing performance.

From a practical standpoint, adopting a “sloping floor + circular pipe” aeration system presents a promising pathway to revolutionize deep bed dryer efficiency. The approach directly addresses the lingering challenge of inhomogeneous drying, which often catalyzes mold growth and other post-harvest losses. By enhancing airflow uniformity and controlling the drying environment’s temperature and humidity distribution, this optimized system preserves grain integrity, nutritional content, and marketability.

As global demands for rice continue to rise alongside climatic variability and logistical challenges, advancing grain drying technology remains critical in securing stable food supplies, particularly in tropical agricultural regions. Timely and uniform drying can significantly reduce post-harvest losses, improving the profitability and sustainability of rice farming communities while also mitigating health risks associated with mold-contaminated grains.

In conclusion, the interdisciplinary application of computational fluid dynamics and multi-criteria decision analysis represents a state-of-the-art approach in the field of post-harvest processing. The findings by Nurba et al. exemplify how such techniques can lead to concrete technological improvements, offering scalable solutions adaptable across diverse geographic and operational contexts. The study paves the way for future innovations that couple robust simulation methods with data-driven decision frameworks to enhance a broad range of agricultural engineering systems.

The continued development and adoption of optimized aeration designs in deep bed dryers could constitute a major step forward in drought resilience and food security, especially as climate change intensifies environmental stresses on crop storage and processing. Beyond rice, similar methodologies can potentially be adapted to various other grains and agricultural products where drying uniformity is critical. This research thus marks an important milestone toward the smart design of energy-efficient, high-performance drying infrastructures that underpin global agriculture’s future.

Subject of Research: Not applicable

Article Title: Aeration system optimization for a deep bed dryer for paddy grain using computational fluid analysis and the AHP-TOPSIS method

News Publication Date: 6-May-2025

Web References:

https://journal.hep.com.cn/fase/EN/10.15302/J-FASE-2024577

http://dx.doi.org/10.15302/J-FASE-2024577

Image Credits: Diswandi NURBA1,2, Sutrisno S. MARDJAN1, Dyah WULANDANI1,3, Leopold O. NELWAN1, I Dewa Made SUBRATA1

Keywords: Agriculture, Applied sciences and engineering

Tags: aeration system designconvective heat transfer methodsdeep bed dryer technologyefficient grain drying solutionsfood safety and qualitymicrobial contamination in ricemoisture reduction in ricepost-harvest rice handlingpreserving rice shelf lifepreventing rice spoilagerice drying processuniform airflow in drying