Tokyo, Japan – Researchers from Tokyo Metropolitan University have come up with a new way of rolling atomically thin sheets of atoms into “nanoscrolls.” Their unique approach uses transition metal dichalcogenide sheets with a different composition on either side, realizing a tight roll that gives scrolls down to five nanometers in diameter at the center and micrometers in length. Control over nanostructure in these scrolls promises new developments in catalysis and photovoltaic devices.

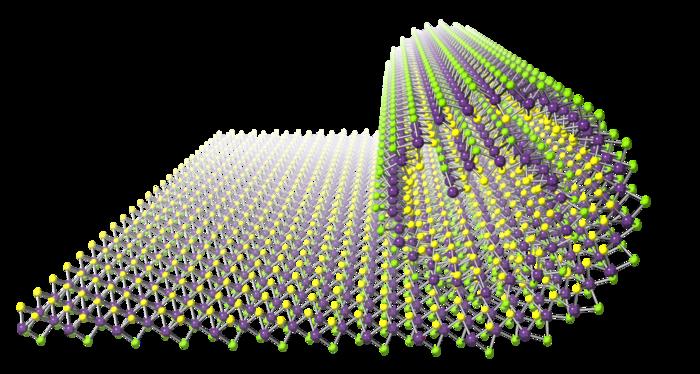

Credit: Tokyo Metropolitan University

Tokyo, Japan – Researchers from Tokyo Metropolitan University have come up with a new way of rolling atomically thin sheets of atoms into “nanoscrolls.” Their unique approach uses transition metal dichalcogenide sheets with a different composition on either side, realizing a tight roll that gives scrolls down to five nanometers in diameter at the center and micrometers in length. Control over nanostructure in these scrolls promises new developments in catalysis and photovoltaic devices.

Nanotechnology is giving us new tools to control the structure of materials at the nanoscale, promising a whole nano-toolset for engineers to create next generation materials and devices. At the forefront of this movement, a team led by Associate Professor Yasumitsu Miyata of Tokyo Metropolitan University have been studying ways to control the structure of transition metal dichalcogenides (TMDC), a class of compounds with a wide range of interesting properties, such as flexibility, superconductivity, and unique optical absorbance.

In their latest work, they set their sights on new ways of making nanoscrolls, nanosheets rolled up into tight scroll-like structures. This is an attractive approach for making multi-walled structures: since the structure of each sheet is the same, the orientations of individual layers are aligned with each other. However, the two existing ways of making nanoscrolls have significant issues. In one, removing sulfur atoms from the surface of the nanosheet creates distortions which cause the sheet to roll up; but by doing so, they destroy the crystal structure of the sheet. In the other, a solvent is introduced between the nanosheet and the substrate, loosening the sheet from the base and allowing the formation of defect-free nanoscrolls. However, tubular structures made like this tend to have large diameters.

Instead of approaches like this, the team have come up with a new way of causing sheets to roll up. Starting with a monolayer molybdenum selenide nanosheet, they treated the nanosheet with a plasma and replaced the selenium atoms on one side with sulfur; such structures are called Janus nanosheets, after the ancient two-faced god. Gentle addition of a solvent then loosens the sheets from the base, which then spontaneously roll into scrolls due to the asymmetry between the sides. These new nanoscrolls are multiple microns in length, significantly longer than previously made single-walled TMDC nanosheets. Furthermore, they were found to be more tightly rolled than ever before, with a center down to five nanometers in diameter, meeting theoretical expectations. The scrolls were also found to interact strongly with polarized light and have hydrogen producing properties.

With unprecedented control over nanostructure, the team’s new method forms the foundation for studying new applications of TMDC nanoscrolls to catalysis and photovoltaic devices.

Journal

ACS Nano

DOI

10.1021/acsnano.3c05681

Article Title

Nanoscrolls of Janus Monolayer Transition Metal Dichalcogenides

Article Publication Date

17-Jan-2024