Older buildings tend to leak heat through their walls, requiring much more energy to maintain a comfortable temperature in summer or winter. Those constructed prior to the late 1970s rarely meet today’s more rigorous energy standards. And yet they account for large proportion of the buildings standing today. In the US, about 44% of the residential building stock was built before 1970 and about half of the commercial buildings that exist today were built before the 1980s, which creates a significant need for energy retrofitting to reduce environmental impact. A new industry-academic collaboration between Jefferson and Lightweight Manufacturing will tackle this problem over the coming year by designing textile-based modular “skins” that can easily and inexpensively cover a building’s façade to improve insulation and energy efficiency.

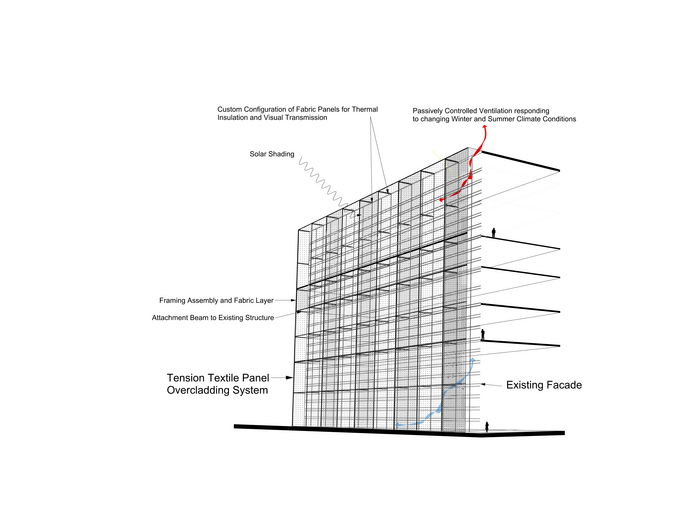

Credit: Kihong Ku, Thomas Jefferson University

Older buildings tend to leak heat through their walls, requiring much more energy to maintain a comfortable temperature in summer or winter. Those constructed prior to the late 1970s rarely meet today’s more rigorous energy standards. And yet they account for large proportion of the buildings standing today. In the US, about 44% of the residential building stock was built before 1970 and about half of the commercial buildings that exist today were built before the 1980s, which creates a significant need for energy retrofitting to reduce environmental impact. A new industry-academic collaboration between Jefferson and Lightweight Manufacturing will tackle this problem over the coming year by designing textile-based modular “skins” that can easily and inexpensively cover a building’s façade to improve insulation and energy efficiency.

“The concept of using stretched fabrics as spatial cover is an old one,” says associate professor of architecture, Dr. Kihong Ku, who’s leading this new partnership to develop what’s called a building overclad. “Teepees and yurts are historical examples of utilizing the tensile strength of fabrics for their lightweight protective properties. We are trying to take advantage of the scientific and engineering developments in functional textiles to bring more sustainable solutions to an urgent architectural problem.”

Overclad approaches have challenges. For example, Exterior Insulation and Finishing Systems (EIFS), or insulated metal panels, can offer reliable thermal insulation over existing masonry or concrete walls. However, when working with these systems, issues such as condensation may require more extensive recladding which ends up being costly and disruptive to daily building use and operations.

Together with Lightweight Manufacturing, Dr. Ku’s team plans to develop fabric-based overclad panels that can be applied to a building’s exterior. The system would help improve the building’s thermal insulation, while retaining light transmission and airflow. “We are looking at functional textiles with all of these properties so that the building envelope can be sealed,” says Dr. Ku. “However, because we plan to create modular panels, it’s also possible to have portions that leave windows uncovered, or covered with transparent foil material such as ETFE, a sort of translucent plastic sheeting used as an exterior wall.” The panels, designed for mid- and high-rise buildings, would use existing structures as support and be fixed using minimally invasive approaches to avoid compromising the existing waterproofing layer.

Dr. Brian George, director of engineering programs at Jefferson, will lend textile engineering expertise to the project, along with an architecture graduate student, and two undergraduate students who will engage in research and development of the system and its market analysis.

The project won funding through a $69,000 Pennsylvania Department of Economic Development grant, which aims to connect PA industry and manufacturing with local universities for their research expertise and brain trust.

“We are excited to be able to support this research project with Thomas Jefferson University, which aims to utilize tensioned fabric facade systems to make existing buildings more energy efficient and extend their useful life,” says Dirk Cos, president of Lightweight Manufacturing.

By the end of the year, the group hopes to have the prototype fabric and frame system ready to test for resistance to wind and weathering, as well as energy performance. The team will work with fabric producers to identify fabrics that can withstand high levels of sun, wind, rain and general weathering in order to hopefully last twenty or more years. “We may need to get creative to create something that can last as long as roof shingles,” says Dr. George.