The energy and transportation sector often make use of different kinds of fluid machinery, including pumps, turbines, and aircraft engines, all of which entail a high carbon footprint. This result mainly from inefficiencies in the fluid machinery caused by flow separation around curved surfaces, which are typically quite complex in nature.

Credit: Tokyo University of Science

The energy and transportation sector often make use of different kinds of fluid machinery, including pumps, turbines, and aircraft engines, all of which entail a high carbon footprint. This result mainly from inefficiencies in the fluid machinery caused by flow separation around curved surfaces, which are typically quite complex in nature.

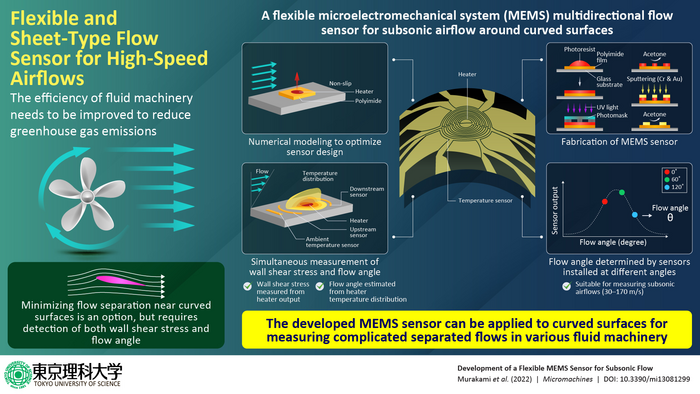

To improve the efficiency of fluid machinery, one, therefore, needs to characterize near-wall flow on the curved surface to suppress this flow separation. The challenge in accomplishing this is multifold. First, conventional flow sensors are not flexible enough to fit into the curved walls of fluid machinery. Second, existing flexible sensors suitable for curved surfaces cannot detect the fluid angle (direction of flow). Moreover, these sensors are limited to only detecting flow separation at speeds less than 30 m/s.

In a new study, Prof. Masahiro Motosuke from the Tokyo University of Science (TUS) in Japan and his colleagues, Mr. Koichi Murakami, Mr. Daiki Shiraishi and Dr. Yoshiyasu Ichikawa from TUS, in collaboration with Mitsubishi Heavy Industries, Japan, and Iwate University, Japan, took on this challenge. As Prof. Motosuke states, “Sensing the shear stress and its direction on curved surfaces, where flow separation easily occurs, has been difficult to achieve in particular without using a novel technique.” Their work was published in Volume 13 Issue 8 of Micromachines on 12 August 2022.

The team, in their study, developed a polyimide thin film-based flexible flow sensor that can be easily installed on curved surfaces without disturbing the surrounding airflow, a key requirement for efficient measurement. To enable this, the sensor was based on microelectromechanical system (MEMS) technology. Moreover, the novel design allowed multiple sensors to be integrated for simultaneous measurement of the wall shear stress and flow angle on the surface of the wall.

To measure the shear stress on the walls, the sensor measured the heat loss from a micro-heater, while the flow angle was estimated using an array of six temperature sensors around the heater that facilitated multidirectional measurement. The team conducted numerical simulations of the air flow to optimize the geometry of the heaters and sensor arrays. Using a high-speed airflow tunnel as the testing environment, the team achieved effective flow measurements with wide range of airflow speeds from (30 – 170) m/s. The developed sensor demonstrated both high flexibility and scalability. “The circuits around the sensor can be pulled out using a flexible printed circuit board and installed in a different location, so that only a thin sheet is attached to the measurement target, minimizing the effect on the surrounding flow,” elaborates Prof. Motosuke.

The team estimated the heater output to vary as the one-third power of the wall shear stress, while the sensor output comparing the temperature difference between two oppositely placed sensors demonstrated a peculiar sinusoidal oscillation as the flow angle was changed.

The developed sensor has the potential for a wide range of applications in industrial-scale fluid machinery that often involve complex flow separation around three-dimensional surfaces. Moreover, the working principle used to develop this sensor can be extended beyond high-speed subsonic airflows.

“Although this sensor is designed for fast airflows, we are currently developing sensors that measure liquid flow and can be attached to humans based on the same principle. Such thin and flexible flow sensors can open up many possibilities,” highlights Prof. Motosuke.

Taken together, the novel MEMS sensor could be a game-changer in the development of efficient fluid machineries with reduced detrimental effects on our environment.

***

Reference

DOI: https://doi.org/10.3390/mi13081299

About The Tokyo University of Science

Tokyo University of Science (TUS) is a well-known and respected university, and the largest science-specialized private research university in Japan, with four campuses in central Tokyo and its suburbs and in Hokkaido. Established in 1881, the university has continually contributed to Japan’s development in science through inculcating the love for science in researchers, technicians, and educators.

With a mission of “Creating science and technology for the harmonious development of nature, human beings, and society”, TUS has undertaken a wide range of research from basic to applied science. TUS has embraced a multidisciplinary approach to research and undertaken intensive study in some of today’s most vital fields. TUS is a meritocracy where the best in science is recognized and nurtured. It is the only private university in Japan that has produced a Nobel Prize winner and the only private university in Asia to produce Nobel Prize winners within the natural sciences field.

Website: https://www.tus.ac.jp/en/mediarelations/

About Professor Masahiro Motosuke from Tokyo University of Science

Masahiro Motosuke is a Professor in the Department of Mechanical Engineering at the Tokyo University of Science (TUS), Japan. He earned his PhD in Engineering from Keio University, Japan, and has held positions at the Japan Society for the Promotion of Science and the Technical University of Denmark. His research into thermofluidics and thermofluidics-based sensors has resulted in multiple journal articles, conference papers and book chapters. Prof. Motsuke has received multiple awards for his research from professional organizations such as the Heat Transfer Society of Japan. For more information, visit: https://www.rs.tus.ac.jp/motlab/en/index.html

Funding information

This study received no external funding.

Journal

Micromachines

DOI

10.3390/mi13081299

Method of Research

Experimental study

Subject of Research

Not applicable

Article Title

Development of a Flexible MEMS Sensor for Subsonic Flow

Article Publication Date

12-Aug-2022