Credit: TECHNOLOGY

A team of researchers from Tufts University in Medford, MA have put together a review article, which discusses recent developments in stimuli-responsive membranes with an emphasis on membranes manufactured by polymer self-assembly. The article describes the state-of-art stimuli-responsive mem-brane manufacturing processes followed by examples explaining their stimuli-responsive behaviors. In the end, an overview of future development and challenges in this field is highlighted. The subject covered by the review article is a new and promising field. The report appears in the December 2016 issue of the journal TECHNOLOGY.

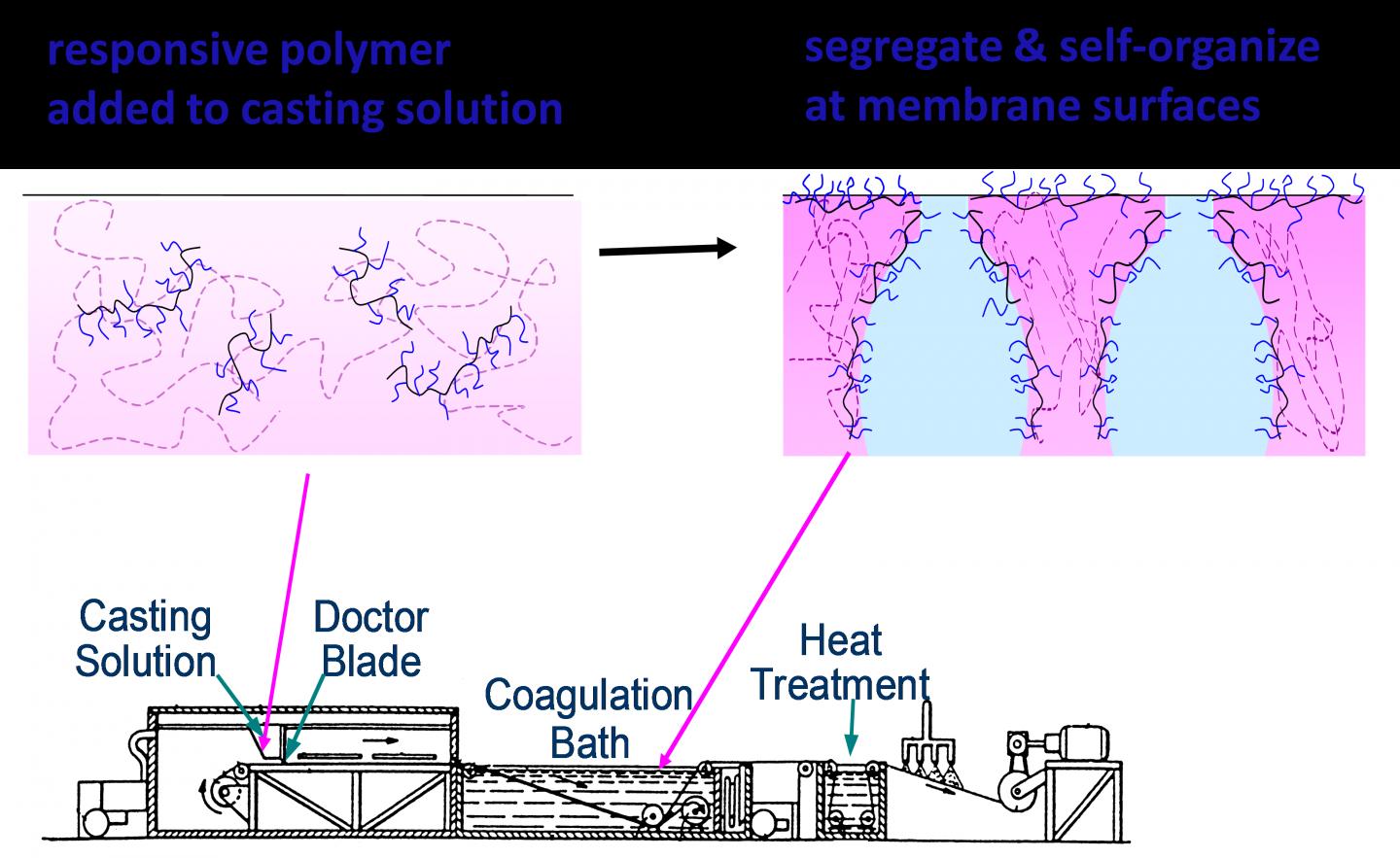

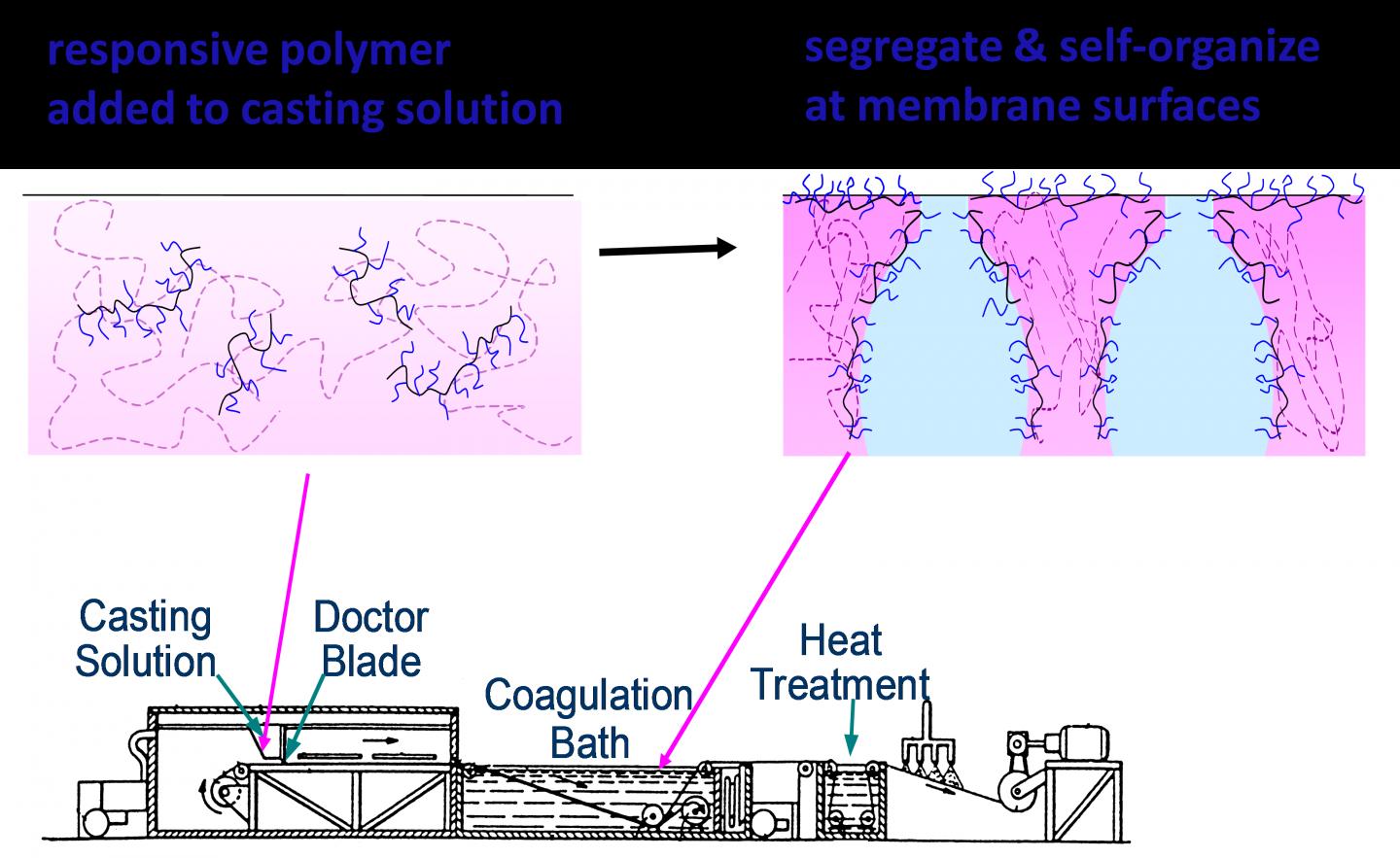

Today, the most common method of manufacture for most ultrafiltration (UF) membranes is the non-solvent induced phase separation (NIPS) process. In NIPS, a polymer solution is cast on a solid substrate, and then immersed in a coagulation bath filled with a non-solvent or a mixture of non-solvents (Figure 1). The non-solvent in coagulation bath diffuses into the polymeric solution and the solvent in polymeric solution diffuses into the non-solvent bath, which essentially is an exchange between the solvents called the demixing process. UF membranes with their nanometer-scale pores allow for the size-based separation of different components. Yet, all NIPS-prepared membranes with a mesoporous skin display a fairly broad pore size distribution in their selective layer, which is a bottleneck in selectivity for size-based separations.

Polymer self-assembly, where polymer chemistry and physics act in concert to create well-defined nanometer-scale features that can act as pores, offers the benefit of improved size-based selectivity. Several researchers have investigated processes that are scalable and compatible with the conventional NIPS process that take advantage of this.

Membrane preparation by NIPS using stimuli-responsive polymers, copolymers, and polymer-additive mixtures is an attractive approach in developing responsive membranes. The conformation/polarity/reactivity of responsive polymers or functional groups integrated in the pore structure changes in response to the stimuli they are designed for, enabling their use in systems or devices that require switchable on-demand material properties Based on the particular behavior and application, polymers can be custom-designed to respond to different external stimuli such as temperature, pH, magnetic or electric fields, ionic strength, added saccharides, antigen binding, or light. Furthermore, mem-branes that respond to multiple types of stimuli can be developed by incorporation of different stimuli-responsive functionalities in the polymer, to respond, e.g., to both pH and temperature.

Corresponding author for this study in TECHNOLOGY is Professor Ayse Asatekin, Ph.D., [email protected]. Other co-authors are Papatya Kaner, Prity Bengani-Lutz, and Ilin Sadeghi, all from the Smart Polymers, Membranes and Separations Laboratory at Tufts University.

###

Media Contact

CHEW Mun Kit

[email protected]

65-646-65775

@worldscientific

http://www.worldscientific.com

############

Story Source: Materials provided by Scienmag