Credit: POSTECH

Thermoelectric (TE) conversion offers a carbon-free power generation from geothermal, waste, body or solar heat, and shows promise to be the next-generation energy conversion technology. At the core of such TE conversion, there lies an all solid-state thermoelectric device which enables energy conversion without the emission of noise, vibrations, or pollutants. To this, a POSTECH research team proposed a way to design the next-generation thermoelectric device that exhibits remarkably simple manufacturing process and structure compared to the conventional ones, while displaying improved energy conversion efficiency using the spin Seebeck effect (SSE).1

A POSTECH joint research team – led by Professor Hyungyu Jin and Ph.D. candidate Min Young Kim of the Department of Mechanical Engineering with Professor Si-Young Choi of the Department of Materials Science and Engineering – has succeeded in designing a highly efficient thermoelectric device by optimizing the properties of both the interior and surface of the magnetic material that makes up the SSE thermoelectric device. This is a pioneering study to show the possibility of fabricating a next-generation thermoelectric device by utilizing the SSE, which has remained in fundamental research. These research findings were recently published in the online edition of Energy and Environmental Science, an international academic journal in the field of energy.

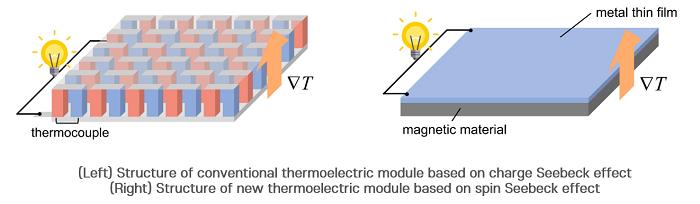

Conventional TE devices rely on the charge Seebeck effect, a thermoelectric effect wherein a charge current is generated in the direction parallel to an applied temperature gradient in a solid material. This longitudinal geometry complicates the device structure and limits manufacturing such TE devices (Figure 1).

The research team fabricated a nickel ferrite (NFO) – platinum (Pt) bilayer SSE device by thinking outside the box – they realized that the device structure can be made much simpler by utilizing the transverse TE effect where a charge current is generated in the direction perpendicular to the applied temperature gradient (Figure 2). When a temperature gradient is applied in the height direction of the device, the spin current generated in the NFO magnetic material is transferred to the interface between NFO and Pt, injected into the Pt, then converted into an electric current inside the Pt. The current generated at this time flows in a direction perpendicular to the applied temperature gradient. By using this SSE, it is possible to construct a device structure that is simpler and easier to scale up compared to conventional thermoelectric devices (Figure 1).

In order to utilize the SSE device, it requires dramatic improvement in structure and efficiency. To this, the research team devised a simple heat treatment method to improve the efficiency of the NFO-Pt thermoelectric device. It was discovered through an observation using a scanning transmission electron microscopy, that a unique microstructure can be formed inside the NFO material by heating it at a high temperature of 1200°C or higher for a certain duration, then heating at a higher temperature for a given time then cooling. In addition, the team also confirmed that the same heat treatment technique can also significantly improve the quality of the interface between NFO and Pt. Finally, it was shown that these two effects can greatly improve the thermoelectric efficiency of the device.

“In this study, we have explained and presented the principles behind fabricating the next-generation TE device with a much simpler structure than conventional ones using the SSE and a method that can dramatically improve its efficiency through a simple heat treatment technique,” remarked Professor Hyungyu Jin who led the study. He added, “If this leads to the development of highly efficient TE devices in the future, it shows promise to ultimately contribute to mitigating both energy and climate challenges.”

###

This study was conducted with the support from the Young Researcher Program, the Strategic International Collaborative Research Program, and the Global Frontier Hybrid Interface Materials of the National Research Foundation of Korea, and the National Research Facilities and Equipment Center Program of the Korea Basic Science Institute.

Media Contact

Jinyoung Huh

[email protected]

Original Source

https:/

Related Journal Article

http://dx.