3D printing of polymer inks in embedding media to fabricate freeform and overhang structures may find applications in rapid prototyping of actuators and antennas

Credit: SUTD

Fabrication of 3D freeform structures of thermoplastics involving overhang (non-anchored) structures is successfully showcased by fused deposition modeling (FDM) and direct ink writing (DIW), yet limited in terms of applicable materials and conditions of printing. 3D printing of freeform structures requires support materials that enable printing of thermoplastics in non-anchored locations.

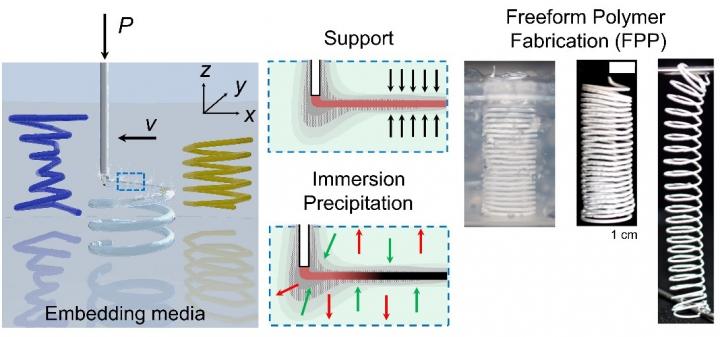

In order to address the difficulty of freeform fabrication via extrusion-based printing, the use of microparticulate gels as embedding media has been widely explored. Such methods are collectively termed embedded 3D printing (e3DP).

In these demonstrations, the gels behaved as Bingham plastics with a low modulus and low yield stress during the printing of low-viscosity resins. e3DP enabled the freeform fabrication of different materials such as silicones, hydrogels, casting alloys, colloids, and hydrogels containing living cells.

Despite all these successful studies, freeform fabrication of thermoplastics has not been demonstrated with e3DP. This is because the molten thermoplastics and the nozzles are typically greater than 100°C, and they are not compatible with the support media consisting of microparticulate hydrogels.

Researchers from the Singapore University of Technology and Design’s (SUTD) Soft Fluidics Lab developed a simple method to 3D print thermoplastics using embedded media in freeform manners, termed freeform polymer precipitation (FPP).

In FPP, microparticulate gels as surrounding media simultaneously offered two essential functions. The microparticulate gels provided structural support to the printed ink and induced the phase change of the printed ink via immersion precipitation. 3D printing based on immersion precipitation with surrounding microparticulate has unlocked the capability of freeform fabrication of thermoplastics.

The study demonstrated the use of both water-based and ethanol-based microparticulate gels as surrounding gels that allowed the increased numbers of solvents and polymers to be used in FPP. Polymer inks with low polymer concentrations (with low viscosity) and inks with pore-inducing agents conferred internal porosity to the printed structures.

“Our approach has overcome the limitation of use of microparticulate media for the fabrication of freeform structures of thermoplastics, for the first time, using the immersion precipitation of polymer inks in microparticulate gels,” said the lead author of the paper Dr Rahul Karyappa from SUTD.

“FPP offers a unique way to fabricate mechanically strong components consisting of thermoplastics in various 3D shapes without support materials. This expands the available technologies of additive manufacturing,” added principal investigator, Associate Professor Michinao Hashimoto from SUTD.

###

This paper titled ‘Freeform Polymer Precipitation in Microparticulate Gels’ has been published in ACS Applied Polymer Materials, a leading journal that encourages original research covering all aspects of engineering, chemistry, physics, and biology relevant to applications of polymers.

Media Contact

Jessica Sasayiah

[email protected]

Related Journal Article

http://dx.