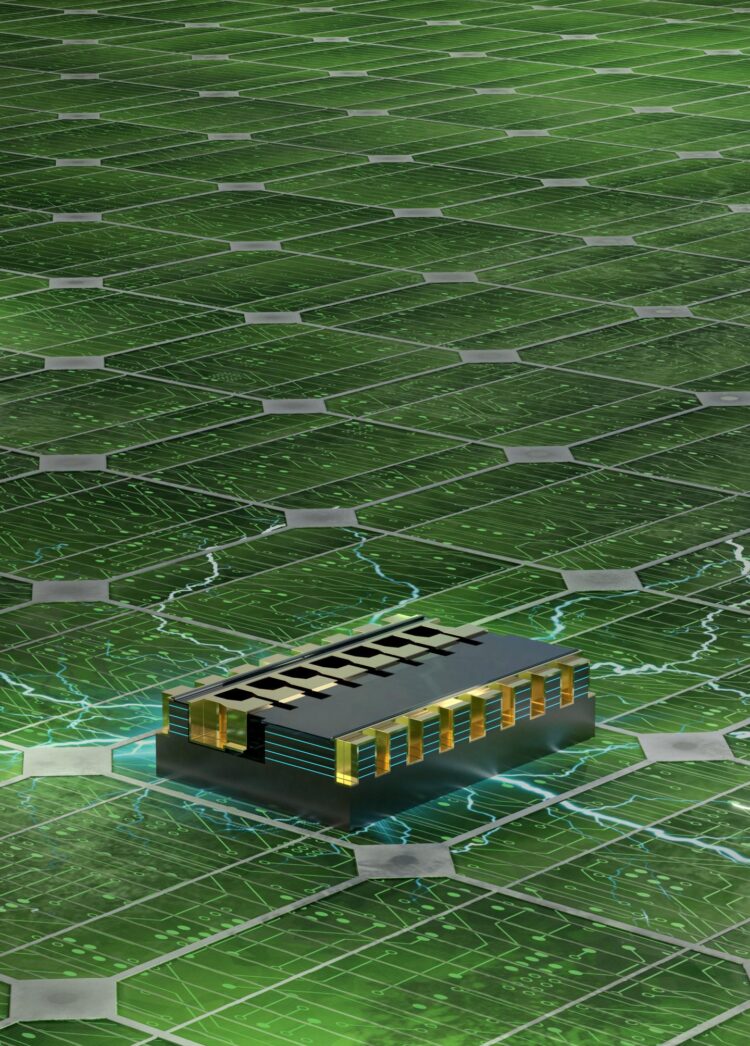

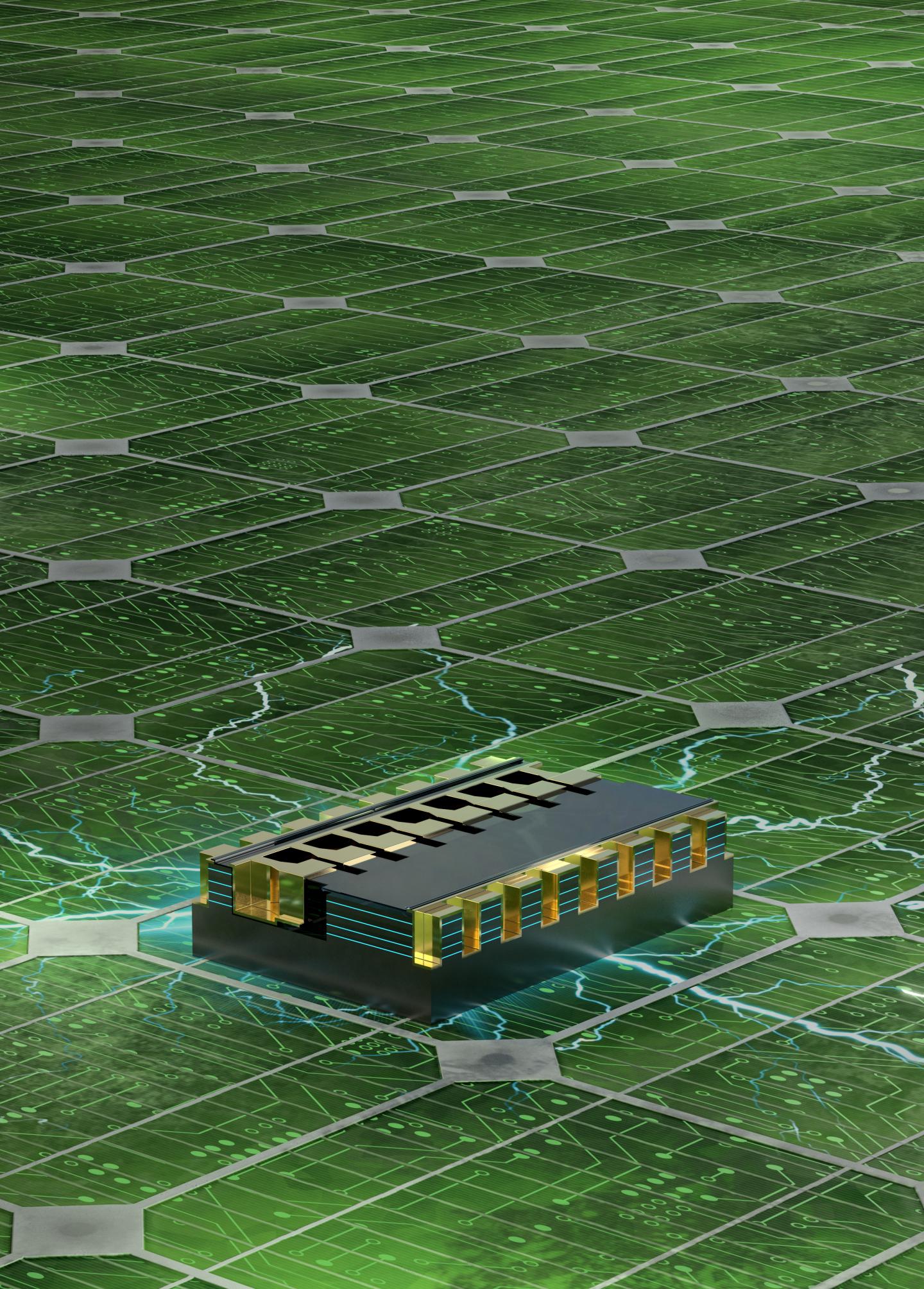

Credit: © EPFL

Power converters are the little-known systems that make electricity so magical. They are what allow us to plug in our computers, lamps and televisions and turn them on in a snap. Converters transform the alternating current (AC) that comes out of wall sockets into the exact level of direct current (DC) that our electronics need. But they also tend to lose, in average, up to 20% of their energy in the process.

Power converters work by using power transistors – tiny semiconductor components designed to switch on and off and withstand high voltages. Designing novel power transistors to improve the converters’ efficiency is the aim of the team of EPFL engineers. With their entirely new transistor design, based on the counterintuitive application of nanoscale structures for high voltage applications, much less heat is lost during the conversion process, making the transistors especially well-suited to high-power applications like electric vehicles and solar panels. Their findings have just been published in Nature Electronics.

The heat dissipation in converters is caused by the high electrical resistance, among other factors, which is the biggest challenge in power electronic devices. “We see examples of electric power losses every day, such as when the charger of your laptop heats up,” says Elison Matioli, a coauthor of the paper and head of EPFL’s POWERlab.

This becomes even more of a problem in high-power applications. “The higher the nominal voltage of semiconductor components, the greater the resistance,” he adds. Power losses shorten the ranges of electric vehicles, for instance, and reduce the efficiency of renewable-energy systems.

Matioli, along with his PhD student Luca Nela and their team, have developed a transistor that can substantially reduce the resistance and cut the amount of heat dissipation in high-power systems. More specifically, it has less than half as much resistance as conventional transistors, while holding voltages of over 1,000 V. The EPFL technology incorporates two key innovations.

The first involves building several conductive channels into the component so as to distribute the flow of current – much like new lanes that are added to a highway to allow traffic to flow more smoothly and prevent traffic jams. “Our multi-channel design splits up the flow of current, reducing the resistance and overheating,” says Nela.

The second innovation involves using nanowires made of gallium nitride, a semiconducting material ideal for power applications. Nanowires are already used in low-power chips, such as those in smartphones and laptops, not in high voltage applications. The POWERlab demonstrated nanowires with a diameter of 15 nm and a unique funnel-like structure enabling them to support high electric fields, and voltages of over 1,000 V without breaking down.

Thanks to the combination of these two innovations – the multi-channel design that allows more electrons to flow, and the funnel structure that enhances the nanowires’ resistance – the transistors can provide greater conversion efficiencies in high-power systems. “The prototype we built using slanted nanowires performs twice as well as the best GaN power devices in the literature,” says Matioli.

While the engineers’ technology is still in the experimental phase, there shouldn’t be any major obstacles to large-scale production. “Adding more channels is a fairly trivial matter, and the diameter of our nanowires is twice as big as the small transistors made by Intel,” says Matioli.?The team has filed several patents for their invention.

Demand for chips that can perform efficiently at high voltages is set to boom as electric vehicles become more widely adopted, since more efficient chips translate directly into longer ranges. Several major manufacturers have expressed interest in teaming up with Matioli to further develop this technology.

###

Media Contact

Elison Matioli

[email protected]

Related Journal Article

http://dx.