Credit: Yongjian Yang, Penn State

Rapid, accurate communication worldwide is possible via fiber optic cables, but as good as they are, they are not perfect. Now, researchers from Penn State and AGC Inc. in Japan suggest that the silica glass used for these cables would have less signal loss if it were manufactured under high pressure.

“Signal loss means that we have to use amplifiers every 80 to 100 kilometers (50 to 62 miles),” said John C. Mauro, professor of materials science and engineering, Penn State. “After that distance, the signal wouldn’t be detected properly. Across continents or across oceans that becomes a big deal.”

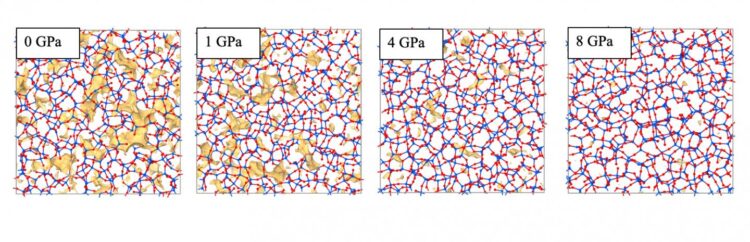

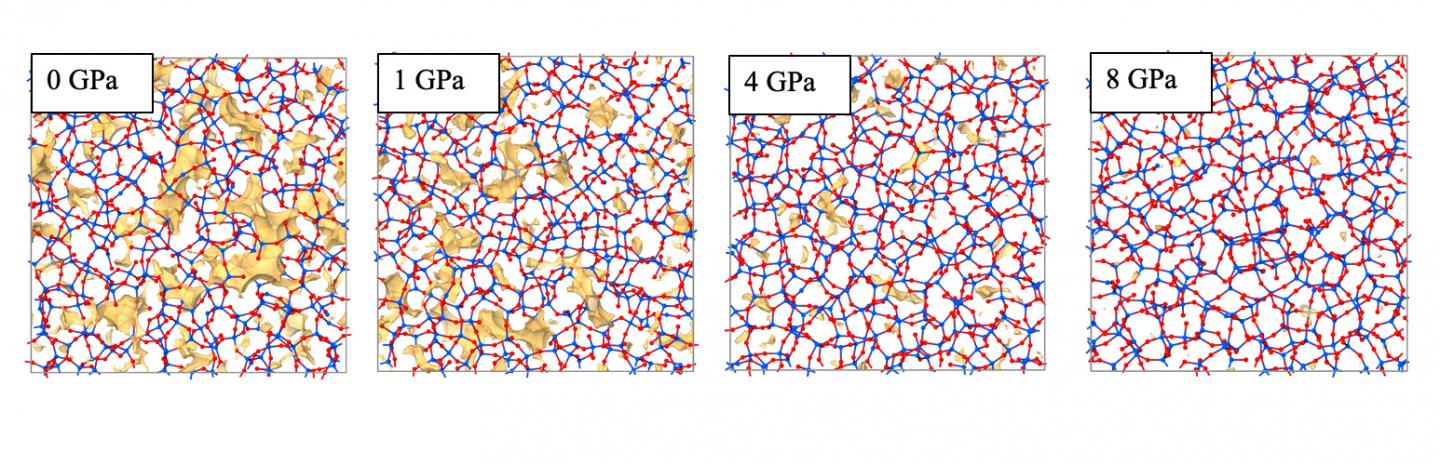

Glass fibers lose signal strength because of Rayleigh scattering — scattering of light that comes from fluctuations in the glass’s atomic structure.

“Glass, on an atomic scale, is heterogeneous,” said Mauro. “It has an open porosity on an atomic scale that occurs randomly.”

The strands in fiber optical cables are made from ultra-high purity silica glass.

“Historically, the biggest breakthrough was the discovery that led to the original optical fiber — how to get rid of the water in the glass,” said Mauro.

Normally glass has a lot of water that absorbs the signal at the frequencies commonly used for telecommunications. Using a modified form of chemical vapor deposition, the fibers could be made free of water. But, like nearly all glass, optical fibers are manufactured at ambient pressure.

Mauro and his team used molecular simulations to investigate the effects of pressure when making optical fibers. They reported their results in npj Computational Materials. The simulations showed that using pressure quenching of the glass, the Rayleigh scattering loss could be reduced by more than 50%.

Pressure treatment of the glass would make the material more homogeneous and decrease the microscopic holes in the structure. This would create a higher mean density material with less variability.

“We were looking for the independent processes that can control mean and variance,” said Mauro. “We realized that the pressure dimension had not been explored previously.”

Mauro’s work is a molecular simulation, but Madoka Ono of AGC Inc.’s Materials Integration Laboratories, who is an associate professor in the Research Institute for Electronic Science at Hokkaido University in Japan, tested bulk pieces of silica glass and found that the results matched the simulation.

“The optimum pressure we found was 4 gigapascals,” said Mauro. “But there is still a process challenge that needs to be addressed.”

To manufacture optical fiber under pressure, the glass would need to be formed and cooled under pressure while it is in the glass transition phase — the temperatures when glass is sticky, not a solid and not truly liquid. To do this would require a pressure chamber capable of 40,000 atmospheres.

###

Also working on this project were Yongjian Yang, postdoctoral fellow in materials science and engineering, Penn State; and Osamu Homma and Shingo Urata, AGC Inc.

AGC Inc. and Penn State’s Institute for Computational and Data Sciences’ ROAR computer (formerly the CyberScience Advanced Cyberinfrastructure) supported this research.

Media Contact

A’ndrea Elyse Messer

[email protected]

Related Journal Article

http://dx.