SUTD researchers’ new approach finds that preheating gelatin extended its 3D printing time compared to freshly prepared gelatin and enhanced the printability of the ink, which is essential for extrusion-based bioprinting and food printing.

Credit: SUTD

Researchers from the Singapore University of Technology and Design (SUTD) demonstrated a simple yet effective approach to increase the printing time of gelatin by preheating it before mixing the gelatin with transglutaminase.

Gelatin has often been hailed as a promising candidate for bioprinting and 3D food printing because it is generally inexpensive to produce, edible and non-toxic to cells. However, gelatin is unable to retain its structure and melts at body temperature. Therefore, 3D printing of gelatin often includes transglutaminase (also known as meat glue), an enzyme which facilitates bonding between amino acids within the gelatin. However, the fast bond formation results in the rapid solidification of the liquid gelatin ink, forming clumps in the ink which lowers the quality of the 3D printed structures and clogs the nozzle during printing.

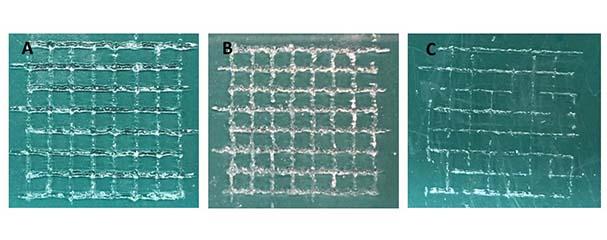

To overcome this limitation, the researchers from the Soft Fluidics Lab at SUTD developed a method to preheat the liquid gelatin ink and demonstrated the increase in printing duration of the gelatin ink in direct ink writing (DIW) 3D printing. The team found that preheating gelatin prior to 3D printing increased its printing time and produced high quality prints over a longer period of time (refer to figure).

Extensive studies on the rheological properties of preheated and freshly prepared gelatin were conducted to understand the differences in their print behaviours. The study also showed that preheated gelatin exhibited greater change in volume in phosphate buffer saline, which allowed for size changes post-printing.

“This inexpensive and simple approach has many useful applications involving gelatin in 3D printing, especially in the fields of food and medicine,” said the lead author and post-doctoral research fellow from SUTD, Dr Justin Tan.

“Gelatin inks are increasingly used in DIW 3D printing to fabricate complex 3D structures that require a long printing duration. We believe that the preheating of gelatin would serve as a facile route to improve the usability of gelatin in extrusion-based processes,” added Assistant Professor Michinao Hashimoto, the principal investigator of the team.

###

The research study was published by the International Journal of Bioprinting, a leading journal that encourages high quality research contributing to the advancement of 3D printing and its applications. Lee Cheng Pau, a PhD candidate at SUTD, also participated in this research project.

Media Contact

Jessica Sasayiah

[email protected]

Related Journal Article

http://dx.