Credit: by Rubaiya Hussain, Mehmet Alican Noyan, Getinet Woyessa, Rodrigo R. Retamal Marín, Pedro Antonio Martinez, Faiz M. Mahdi, Vittoria Finazzi, Thomas A. Hazlehurst, Timothy N. Hunter, Tomeu Coll, Michael Stintz,…

In many industrial and environmental applications, determining the size and distribution of microscopic particles is essential. For example, in the pharmaceutical industry, inline measurement and control of particles containing various chemical ingredients (before consolidation in tablets) may critically enhance the yield and quality of the final medical product. Also, the air we breathe, water we drink and food we eat can also contain many types of unhealthy particulates, which is then crucial to detect for our health and wellbeing.

In a new paper published in Light Science & Application, a team of European scientists and engineers from ICFO and IRIS in Spain, Ipsumio B.V. in the Netherlands, the Technical University of Denmark, the Technische Universität Dresden in Germany and the University of Leeds in the UK, has developed a new micro-particle size analyser by combining consumer electronics products and artificial intelligence. The device, an order of magnitude smaller in terms of size, weight and cost, measures particle size with a precision comparable to commercial light-based particle size analysers at least.

“The EU funded project ProPAT aimed to deliver new sensors for industrial applications. The innovation developed by ICFO is a great example of such sensor. The feedback from pilot scale testing in real world conditions and end-industries moved the sensor from a lab device to potential applicability in industrial environments,” says Frans Muller, professor in chemical process engineering at the University of Leeds and the technical manager of ProPAT.

Conventionally, laser diffraction (LD) based particle size analysers (PSA) are widely used for measuring particle size from hundreds of nanometres to several millimetres. In such devices, laser light focused onto a dilute particle sample produces a diffraction (scattering) pattern, measured by an array of light detectors and converted to a particle size distribution using well-established scattering theory. These devices are precise and reliable but large (each dimension being of the order of half meter), heavy (tens of kg) and expensive (often costing in the order of a hundred thousand dollars or more). In addition, their complexity, together with the fact that they often require maintenance and highly trained personnel, make them impractical, for example in the majority of online industrial applications, which require installation of probes in processing environments, often at multiple locations.

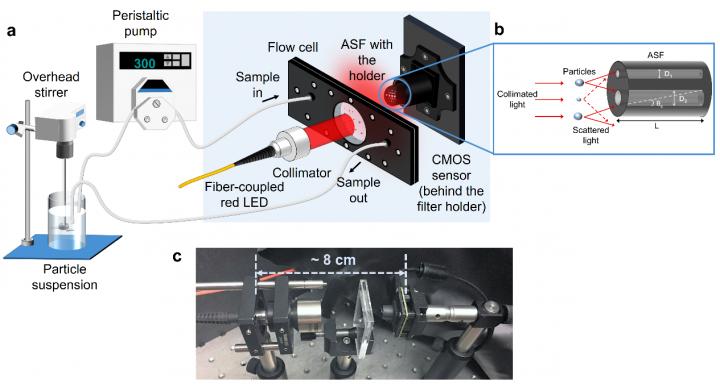

The newly developed PSA works in a collimated beam configuration using a simple LED light emitting diode (LED) and a single metal-oxide-semiconductor (CMOS) image sensor, similar to those used in smart phones. The key-innovation is the small angular spatial filter (ASF) made with an array of holes with different diameters that is extruded from a polymer rod. On illuminating the target sample, light scatters and passes through the ASF onto the sensor. Light collected from different size holes is representative of a different set of scattering angles. An ad hoc machine learning (ML) model converts the sensor image into size of particles. The same device can be easily converted into hazemeter, an essential instrument to characterize many optical materials.

“It is very exciting to see how a simple combination of consumer photonic components, such as an LED and a phone camera, an innovative angular filter fabricated using mass-scalable photonic crystal fiber extrusion and machine learning data processing has allowed us to make such a compact, cheap and precise device”, says Rubaiya Hussain, first author of the paper and PhD candidate in the Optoelectronics group at ICFO.

In order to validate the new PSA, mixtures of water and glass beads with sizes in the range from 13 to 125 micrometre were tested at several process concentrations in liquid dispersions. Laser diffraction systems cannot measure such high concentrations as light is scattered multiple times resulting in scattering patterns that cannot be converted into particles size. Using the random forest machine learning algorithm the data from the new device could be analysed successfully, increasing the working range of particle sizes and concentrations that can be measured.

“We used the PSA device built at ICFO in Barcelona to collect data from different particle size ranges and concentrations of standard glass beads. According to the obtained results and our experience, we were pleased to see that the precision of a few % of the median volume particle size (D50) is comparable with other measurement techniques (e.g. LD) in micrometre range”, says Dipl.-Ing. Rodrigo R. Retamal Marín, researcher in the Mechanical Process Engineering group at theTechnische Universität Dresden.

Future improvements in the optical hardware are also being designed. In particular, further optimisation of the innovative ASF component and refined data capturing methods are being undertaken, to produce larger, higher fidelity datasets for the machine learning algorithm. Future work will also include analysis of non-spherical particles, collected with well-designed sample feeding systems for both dry and wet measurements, leading to high precision analysis for a range of industrially relevant systems.

“We intend to utilize the inherent flexibility of the simple design and low hardware cost of our proprietary PSA for specific applications, for example online or at-line monitoring, and we are looking for partners from various Industries and Research Institutions”, says Valerio Pruneri, ICREA Professor at ICFO and leading author of the work.

###

Media Contact

Valerio Pruneri

[email protected]

Related Journal Article

http://dx.