Credit: Padture Lab / Brown University

PROVIDENCE, R.I. [Brown University] — A new study reveals good news for the possibility of using perovskite materials in next-generation solar cells.

The study, published in the journal Acta Materialia, finds that though perovskite films tend to crack easily, those cracks are easily healed with some compression or a little bit of heat. That bodes well, the researchers say, for the use of inexpensive perovskites to replace or complement pricy silicon in solar cell technologies.

“The efficiency of perovskite solar cells has grown very quickly and now rivals silicon in laboratory cells,” said Nitin Padture, the Otis E. Randall Professor in Brown’s School of Engineering and director of Brown’s Institute for Molecular and Nanoscale Innovation. “Everybody’s chasing high efficiency, which is important, but we also need to be thinking about things like long-term durability and mechanical reliability if we’re going to bring this solar cell technology to the market. That’s what this research was about.”

Perovskites, a broad class of crystalline materials, were first incorporated into solar cells in 2009. Those first perovskite solar cells had a power conversion efficiency of around 4%, but now that exceeds 25% — essentially the same as traditional silicon. The advantage of perovskite solar cells is that they can be made for a fraction of the cost of silicon, potentially cutting the cost of solar power installations. Perovskites can also be made into thin films that are semi-transparent and flexible, potentially clearing the way for energy-generating windows or for lightweight, flexible solar cells in tents or backpacks.

But the low-cost and ease of making perovskite solar cells comes with a cost.

“In material science, things that are easy to make also tend to be easy to break,” said Padture who led the study. “That’s certainly true of perovskites, which are quite brittle. But here we show they’re also quite easy to fix — cracks in perovskite films can be healed by compressing them or with moderate heat.”

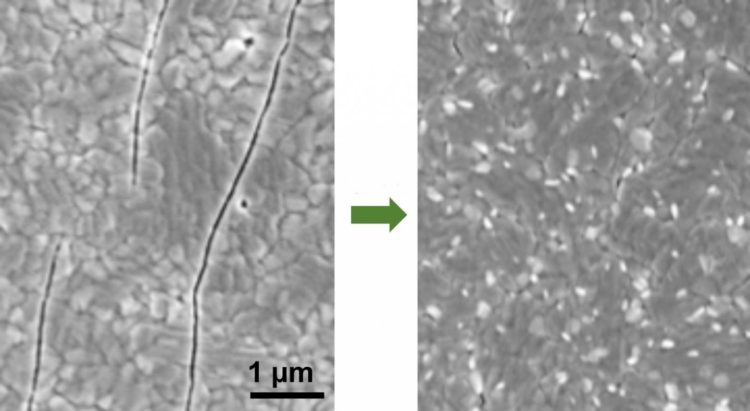

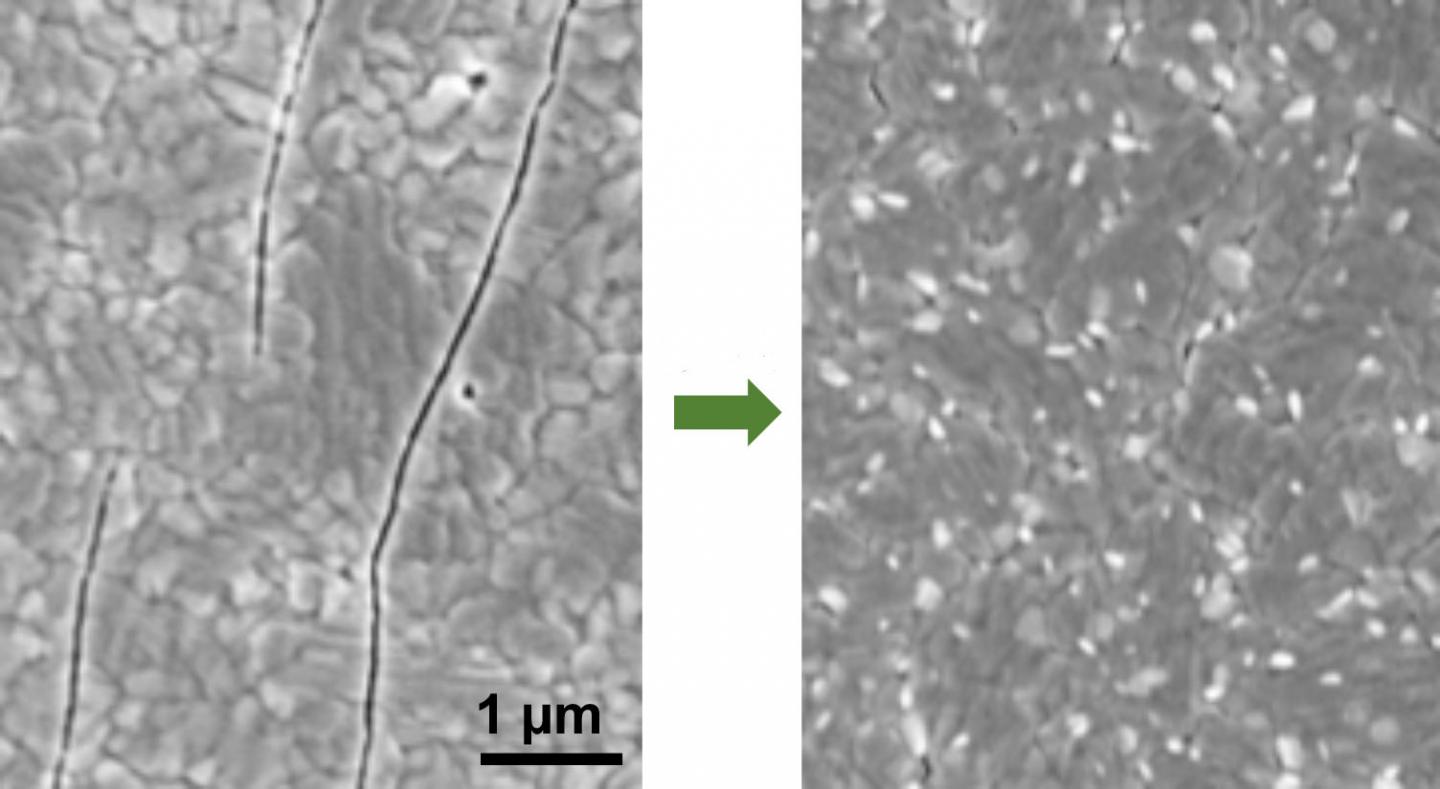

For the study, Srinivas Yadavalli, a doctoral student working in Padture’s laboratory and the first author of the paper, deposited perovskite films on plastic substrates. He then bent the substrate to put tensile (pulling apart) stress on the perovskite film while using a scanning electron microscope (SEM) to detect cracks. Once the film was cracked, the researchers then bent the substrate in the opposite direction to see if compressive stress might heal those cracks.

Sure enough, SEM imaging showed that the cracks had disappeared. To make sure the cracks were fully healed and not merely hidden, the researchers used a technique known as X-ray diffraction. By measuring the size of a material’s atomic lattice, the technique can reveal whether a formerly cracked area is now able to carry a mechanical load — a surefire sign that the crack is healed. Those tests also indicated fully healed cracks.

The researchers found that heat was just as effective in healing cracks. Temperatures around 100 degrees Celsius — quite modest heating by material science standards — were enough to completely heal cracks in perovskite films.

Padture says that the research was aimed at better understanding the basic properties of perovskite materials, and more work needs be done to develop methods of applying this information in a commercial setting. But knowing that perovskite films are easily healed could be useful as these kinds of solar cells move toward commercialization.

“It’s good news,” Padture said. “It suggests that fairly simple healing methods may help maintain performance in these kinds of solar cells.”

###

Co-authors on the paper were Zhenghong Dai, Hua Zhou, and Yuanyuan Zhou. The research was funded by the Office of Naval Research (N00014-17-1-2232) and the National Science Foundation (OIA-1538893). The study used resources of the Advanced Photon Source, a Department of Energy Office of Science User Facility operated by Argonne National Laboratory (DE-AC02-06CH11357).

Media Contact

Kevin Stacey

[email protected]

401-863-3766

Original Source

https:/

Related Journal Article

http://dx.