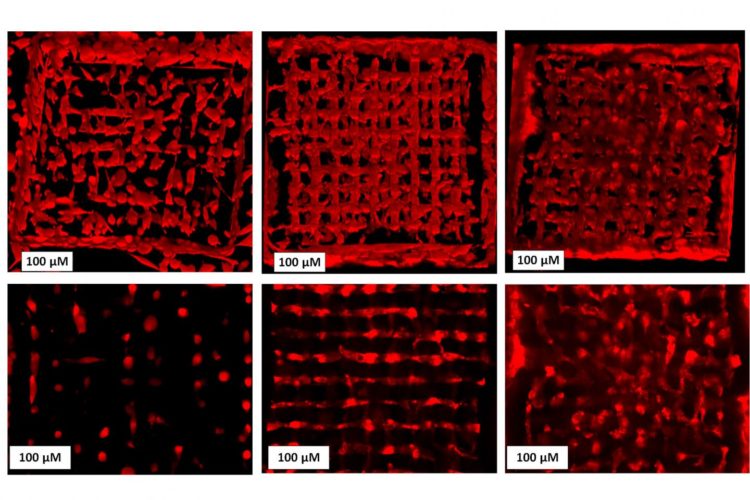

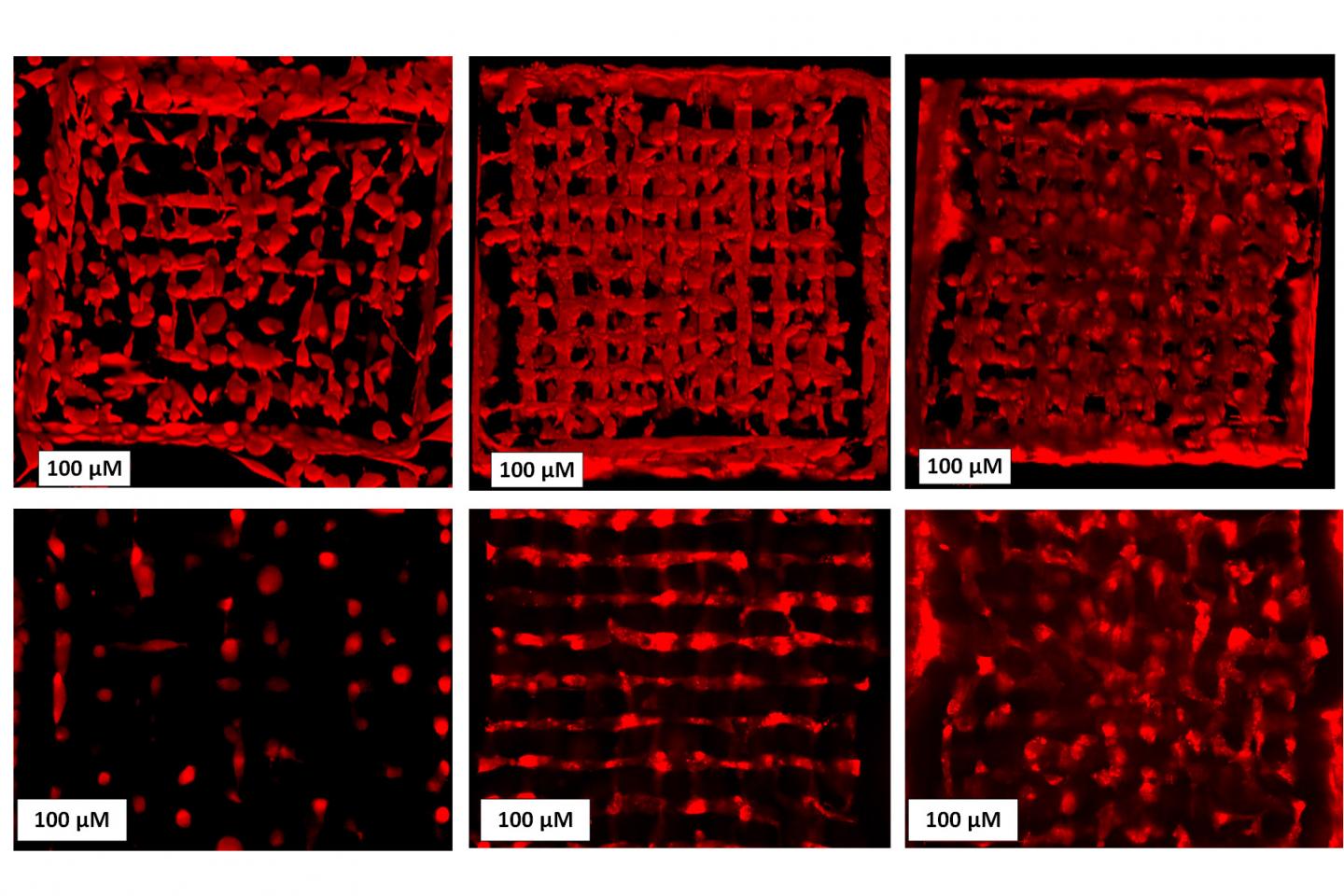

With a new process developed at TU Wien (Vienna), living cells can be integrated into fine structures created in a 3D printer – extremely fast and with very high resolution

Credit: TU Wien

Tissue growth and the behavior of cells can be controlled and investigated particularly well by embedding the cells in a delicate 3D framework. This is achieved using additive 3D printing methods – so called “bioprinting” techniques. However, this involves a number of challenges: Some methods are very imprecise or only allow a very short time window in which the cells can be processed without being damaged. In addition, the materials used must be cell-friendly during and after the 3D biopriting process. This restricts the variety of possible materials.

A high-resolution bioprinting process with completely new materials has now been developed at TU Wien (Vienna): Thanks to a special “bio ink” for the 3D printer, cells can now be embedded in a 3D matrix printed with micrometer precision – at a printing speed of one meter per second, orders of magnitude faster than previously possible.

The environment matters

“The behavior of a cell behaves depends crucially on the mechanical, chemical and geometric properties of its environment,” says Prof. Aleksandr Ovsianikov, head of the 3D Printing and Biofabrication research group at the Institute of Materials Science and Technology (TU Wien). “The structures in which the cells are embedded must be permeable to nutrients so that the cells can survive and multiply. But it is also important whether the structures are stiff or flexible, whether they are stable or degrade over time”.

It is possible to first produce suitable structures and then colonise them with living cells – but this approach can make it difficult to place the cells deep inside the scaffold, and it is hardly possible to achieve a homogeneous cell distribution that way. The much better option is to embed the living cells directly into the 3D structure during the production of the structure – this technique is known as “bioprinting”.

Printing microscopically fine 3D objects is no longer a problem today. However, the use of living cells presents science with completely new challenges: “Until now, there has simply been a lack of suitable chemical substances,” says Aleksandr Ovsianikov. “You need liquids or gels that solidify precisely where you illuminate them with a focused laser beam. However, these materials must not be harmful to the cells, and the whole process has to happen extremely quickly.”

Two photons at once

In order to achieve an extremely high resolution, two-photon polymerization methods have been used at TU Wien for years. This method uses a chemical reaction that is only initiated when a molecule of the material simultaneously absorbs two photons of the laser beam. This is only possible where the laser beam has a particularly high intensity. At these points the substance hardens, while it remains liquid everywhere else. Therefore, this two-photon method is best suited to produce extremely fine structures with high precision.

However, these high resolution techniques usually have the disadvantage of being very slow – often in the range of micrometers or a few millimeters per second. At TU Wien, however, cell-friendly materials can be processed at a speed of more than one meter per second – a decisive step forward. Only if the entire process can be completed within a few hours is there a good chance of the cells surviving and developing further.

Numerous new options

“Our method provides many possibilities to adapt the environment of the cells,” says Aleksandr Ovsianikov. Depending on how the structure is built, it can be made stiffer or softer. Even fine, continuous gradients are possible. In this way, it is possible to define exactly how the structure should look in order to allow the desired kind of cell growth and cell migration. The laser intensity can also be used to determine how easily the structure will be degraded over time.

Ovsianikov is convinced that this is an important step forward for cell research: “Using these 3D scaffolds, it is possible to investigate the behavior of cells with previously unattainable accuracy. It is possible to study the spread of diseases, and if stem cells are used, it is even possible to produce tailor-made tissue in this way”.

###

The research project is an international and interdisciplinary cooperation in which three different institutes of the TU Vienna were involved: Ovsianikov’s research group was responsible for the printing technology itself, the Institute of Applied Synthesic Chemistry developed fast and cell friendly photoinitiators (the substances that initiate the hardening process when illuminated) and the Institute of Lightweight Structures and Structural Biomechanics analyzed the mechanical properties of the printed structures.

The high-resolution 3D Printing technology and the materials are being commercialized the young but very successful TU Wien spin-off UPNano GmbH (https:/

Contact:

Prof. Aleksandr Ovsianikov

Institut für Werkstoffwissenschaft und Werkstofftechnologie

Technische Universität Wien

Getreidemarkt 9, 1060 Wien

T +43-1-58801-30830

[email protected]

Dr. Marica Markovic

Institut für Werkstoffwissenschaft und Werkstofftechnologie

Technische Universität Wien

Getreidemarkt 9, 1060 Wien

T +43-664-605883087

[email protected]

Media Contact

Florian Aigner

[email protected]

0043-158-801-41027

Original Source

https:/

Related Journal Article

http://dx.